Full-rigid air spring capable of being locked in any position

An arbitrary position, gas spring technology, applied in the field of gas springs, can solve the problems of difficult to achieve precision, switch activation and rebound force increase, chronic air leakage, etc., to ensure the sealing effect and lifting effect, reduce the processing and assembly time. Difficulty, descent, and ascent values are evenly distributed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

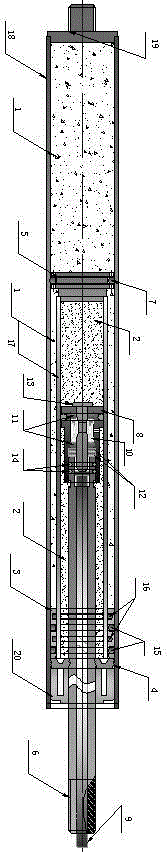

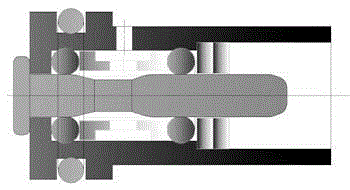

[0023] The air cavity 1 and the oil cavity 2 are separated from the piston 3 and the oil seal 4 by the rear plug 5 located at both ends of the oil pipe. The rear plug 5 is welded to the top of the oil pipe 17 by argon arc welding and sealed. The rear plug 5 is provided with a guide piston 7. Ensure that the oil pipe 17 will not shake from side to side, and the rear end of the oil pipe 17 is reamed so that the piston 3 cannot fall off, and the gas spring can move up and down when it moves up and down. Through the structural design of oil-air separation, the piston rod 6 runs and stretches completely in the oil chamber, so that the locking gas spring can realize full rigid locking at any position and angle, and the floating oil chamber in the air chamber can make the gas spring lift. Press down evenly and easily. One end of the piston rod body 6 is fixedly connected with the piston valve body 8, the center of the piston valve body 8 is provided with a valve needle 13, the contac...

Embodiment 2

[0025] The air cavity 1 and the oil cavity 2 are separated from the piston 3 and the oil seal 4 by the rear plug 5 located at both ends of the oil pipe. The rear plug 5 is welded to the top of the oil pipe 17 by argon arc welding and sealed. The rear plug 5 is provided with a guide piston 7. Ensure that the oil pipe 17 will not shake from side to side, and the rear end of the oil pipe 17 is reamed so that the piston 3 cannot fall off, and the gas spring can move up and down when it moves up and down. Through the structural design of oil-air separation, the piston rod 6 runs and stretches completely in the oil chamber, so that the locking gas spring can realize full rigid locking at any position and angle, and the floating oil chamber in the air chamber can make the gas spring lift. Press down evenly and easily. One end of the piston rod body 6 is fixedly connected with the piston valve body 8, the center of the piston valve body 8 is provided with a valve needle 13, the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com