Construction machine with offset hopper rear walls

A technology of construction machinery and rear wall, which is applied in the field of construction machinery and can solve the problem of reducing the volume of storage materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

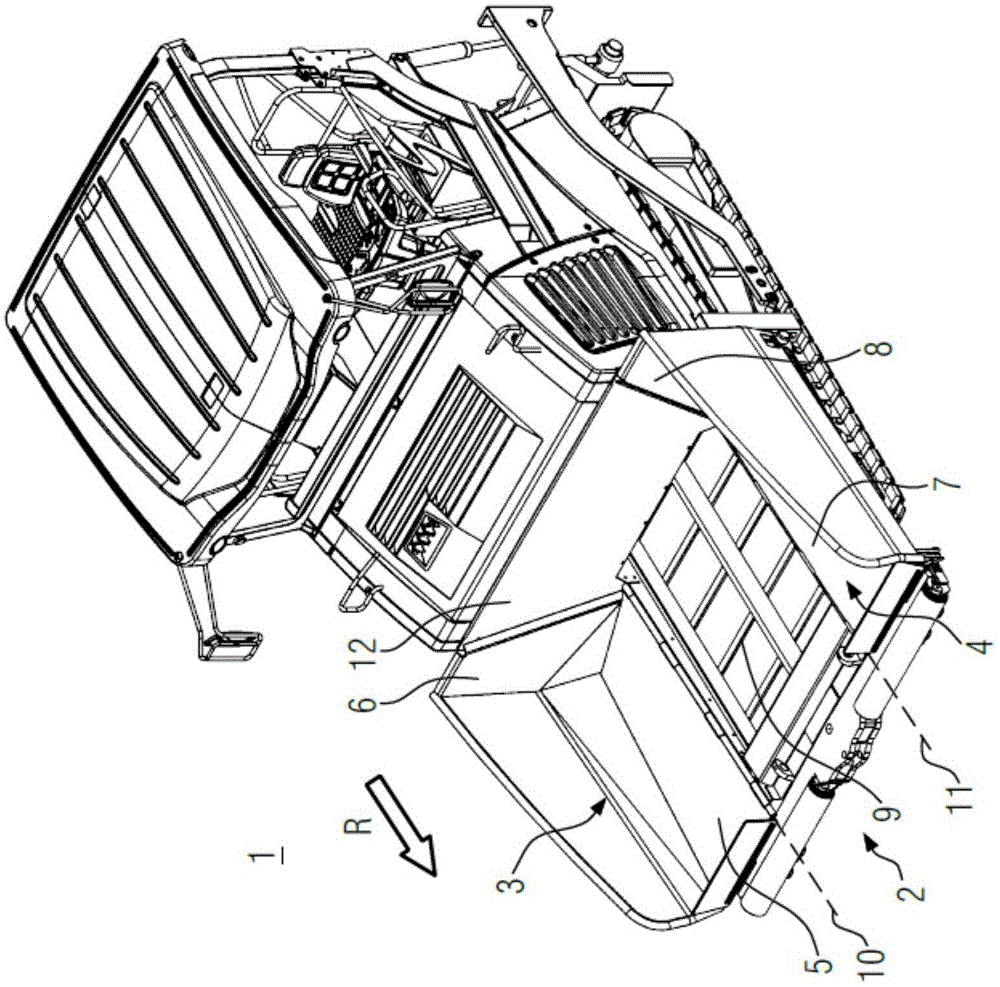

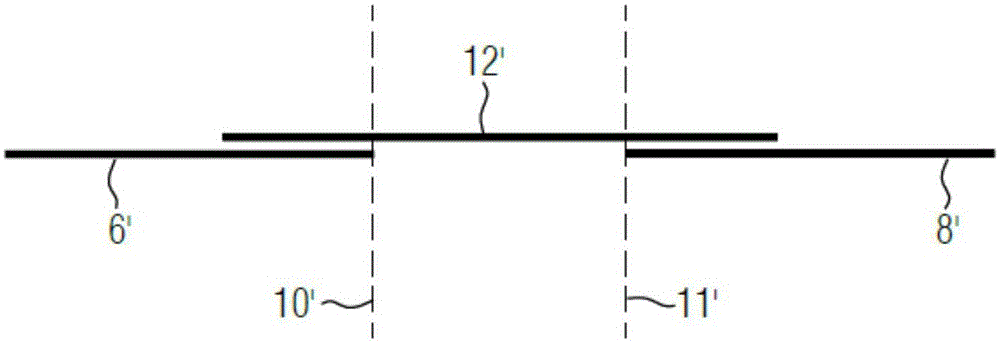

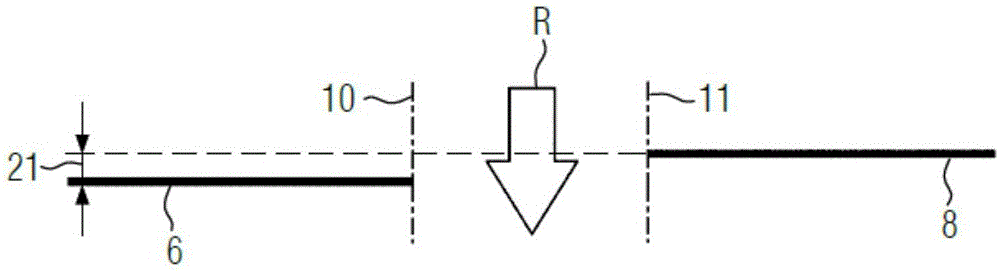

[0033] figure 1 By way of example, a road paver 1 is shown as a construction machine 1 . It moves in direction R of travel. The road paver 1 comprises a material hopper 2 which in the present embodiment comprises first and second sub-hoppers 3 , 4 . However, further additional sub-hoppers are also conceivable. The first sub-hopper 3 comprises a first base region 5 and a first rear wall 6 . Similarly, the second sub-hopper 4 comprises a second base region 7 and a second rear wall 8 .

[0034] Extending between the first sub-hopper 3 and the second sub-hopper 4 is a conveyor device 9 which in the present case conveys bulk material, such as bitumen, in a direction opposite to the direction of travel of the road paver 1 . The first sub-hopper 3 is pivotable about a first axis 10 in order to dump the bulk material located in the first sub-hopper 3 onto the conveyor arrangement 9 . Similarly, the second sub-hopper 4 is pivotable about the second axis 11 in order to dump the bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com