Centrifugal type double-tube activating aeration oxygen increasing machine

An aerator and centrifugal technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem that the outside air cannot be transported and diffused at a high speed, the aeration effect will not be significantly improved, and the range of aeration It can improve the oxygenation effect of water body, eliminate the dead angle of oxygenation, and achieve the effect of reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

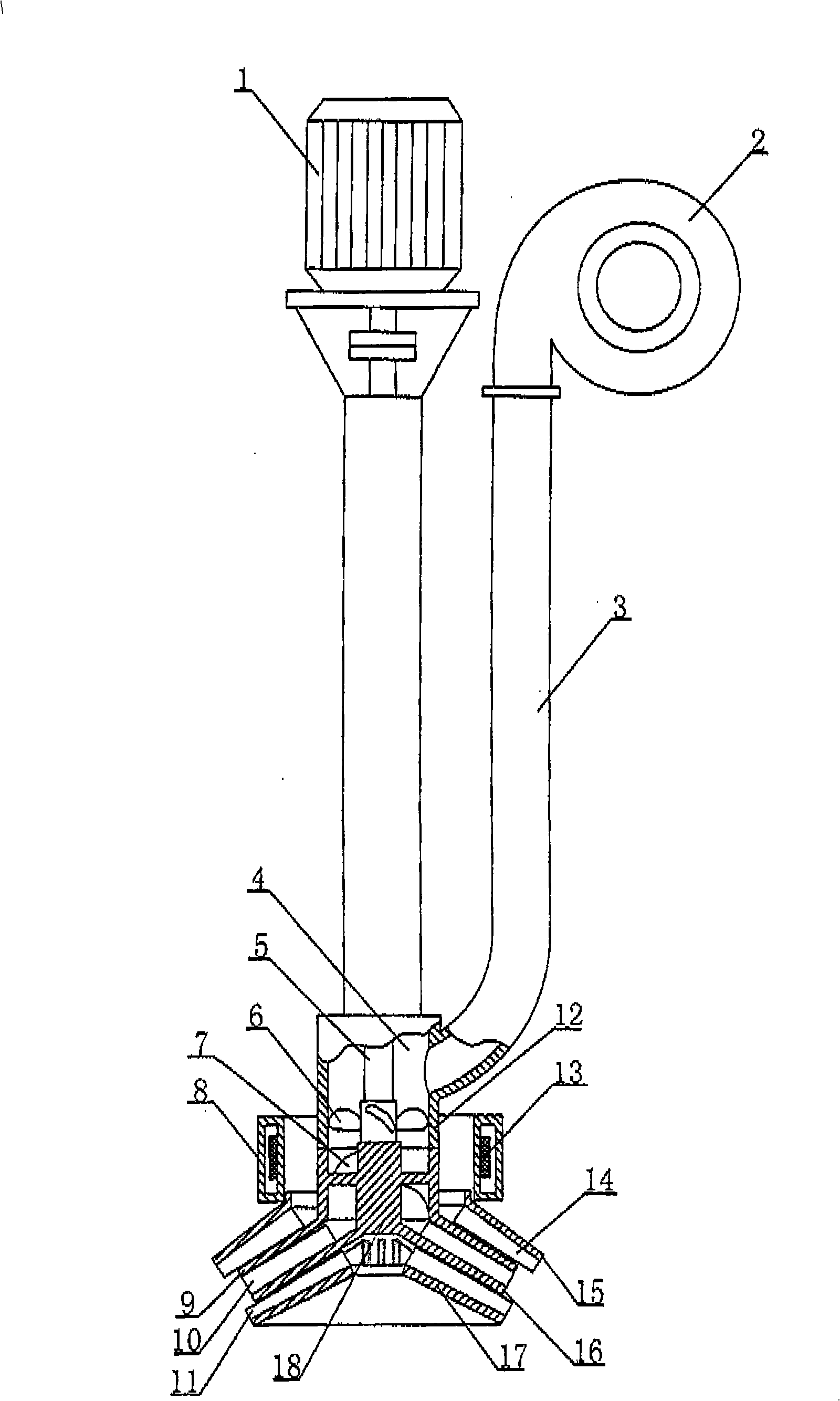

[0024] As shown in FIG. 1 , the centrifugal double-tube activated aeration aerator is mainly composed of a driving device 1 , a main shaft 5 , bell mouth type combined centrifugal paddle 18 , an outer sleeve 12 , an oxygen supply blower 2 and an oxygen supply pipe 3 . The driving device 1 is a motor, and the lower end of the driving device 1 is driven to connect a main shaft 5. The bell mouth type combined centrifugal paddle 18 is installed at the lowermost end of the main shaft 5, and bracket blades 7 are arranged on the main shaft upwardly from the bell mouth type combined centrifugal paddle. and supercharging impeller 6, used to further increase the air pressure entering the air channel and make the air form turbulent flow, the main shaft at the upper end of the trumpet type combined centrifugal paddle is covered with a fixed outer sleeve 12 to form an oxygen gathering chamber 4, and the oxygen gathering chamber 4 is formed. The chamber 4 is connected with an oxygen supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com