Dual-stage sealed filling head

A filling head and filling pipe technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problem of inability to fill the main and auxiliary water tanks, and achieve improved production inspection efficiency, simple structure, and good market application. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

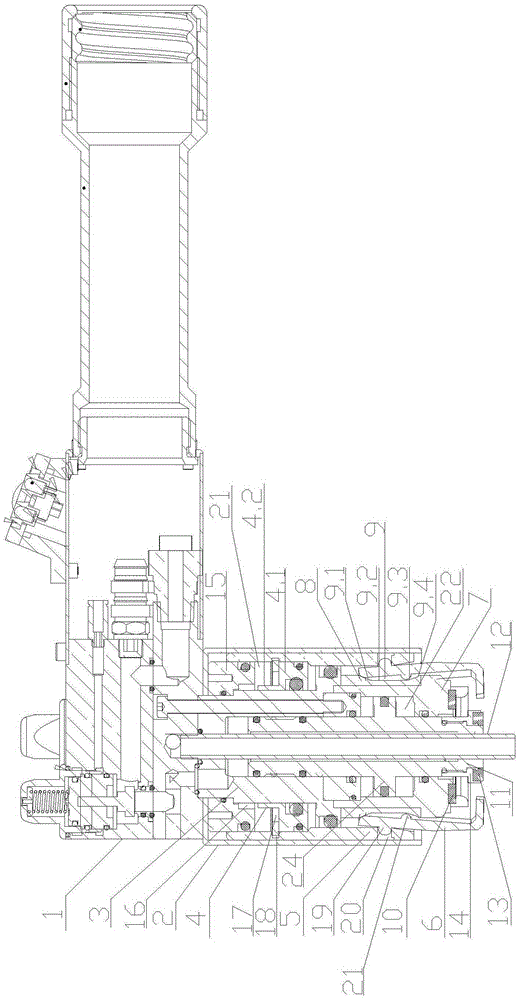

[0018] like figure 1 The double-stage sealed filling head shown includes an upper cylinder body 1 and a lower cylinder body 2, a piston rod 3 is arranged inside the lower cylinder body 2, and a static piston 15 is set on the top of the piston rod 3, and the static piston 15 is set on the top of the piston rod 3. The piston 15 is fixed on the inner surface of the top of the lower cylinder body 2, the upper part of the piston rod 3 is sleeved with a movable piston 4, the movable piston 4 is sleeved with a lift valve 5, and the lift valve 5 is set on the static piston 15 and the inner side wall of the lower cylinder body 2; the lower part of the poppet 5 is provided with a catch 6 along its circumference, and the lower part of the piston rod 3 is provided with a nested cylinder 7, and the bottom of the nested cylinder 7 is fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com