Differential Rail Container Crane

A container crane, differential technology, applied in the direction of cranes, trolley cranes, traveling mechanisms, etc., can solve the problems of large active load of the trolley, damage to the main beam structure, large inertia of the trolley, etc., to reduce weight and drive energy consumption. , the effect of reducing the inertia of starting or braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

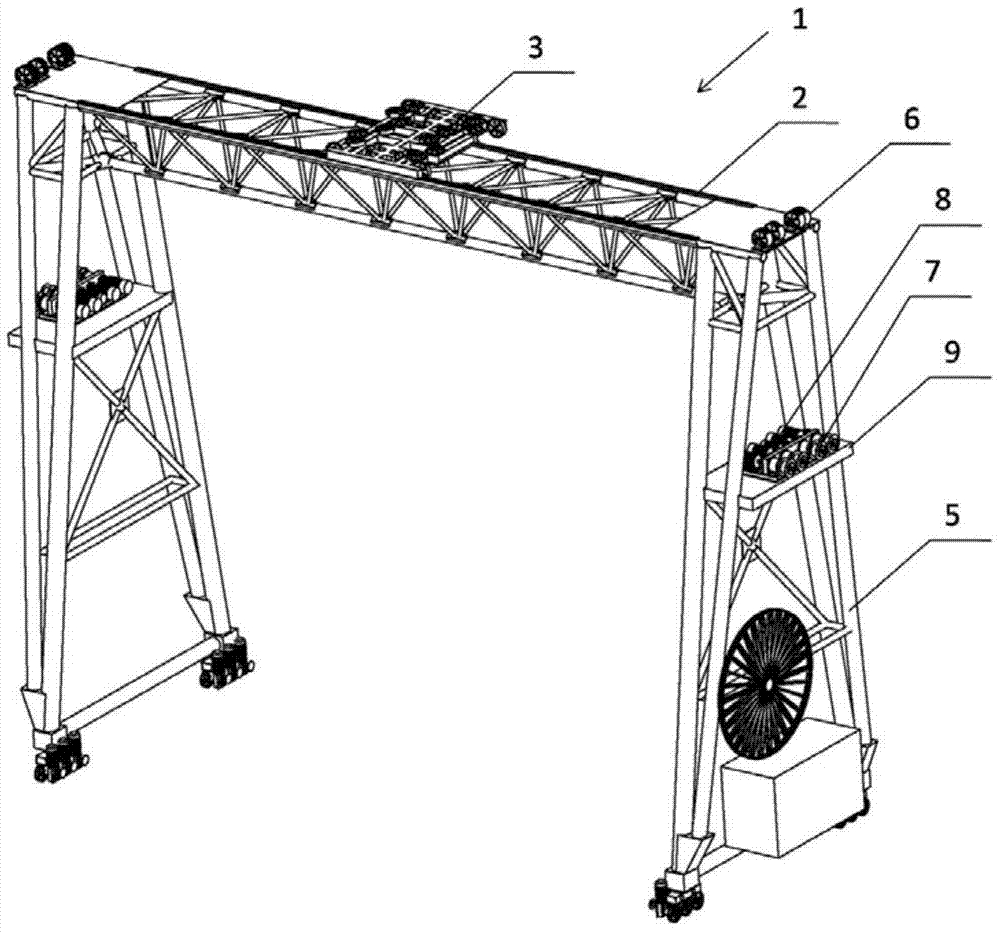

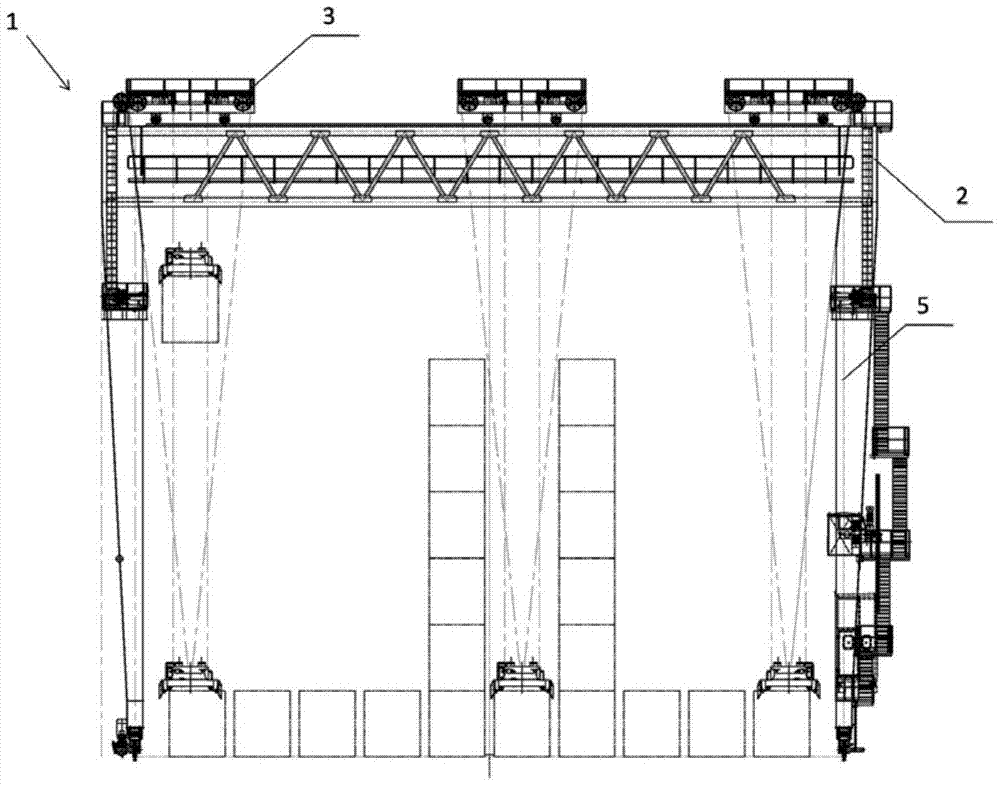

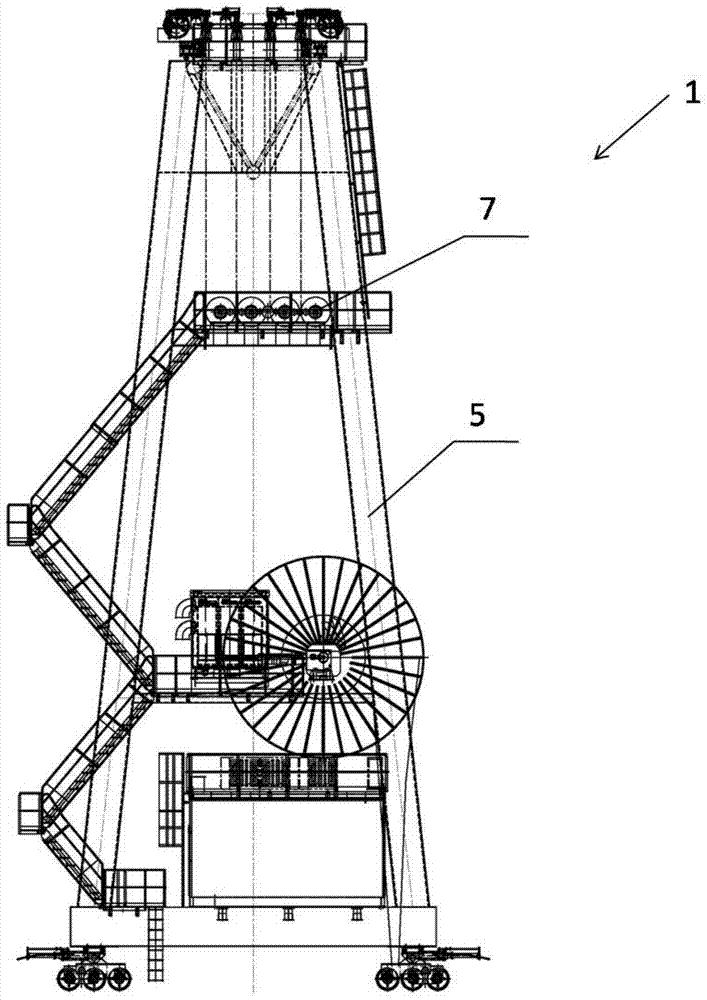

[0032] Such as Figure 1 to Figure 4 As shown, this embodiment provides a differential rail container crane, which includes: a mast structure 1 , a trolley 3 and a driving mechanism for driving the trolley to travel on the top of the mast mechanism 1 .

[0033] Wherein, the portal frame structure 1 includes a load-bearing main beam 2 and two support frames 5 for supporting the load-bearing main beam 2 . The load-bearing main girder is a triangular tube structure single main girder and its node form is a contained node. The parameters of the single main girder of the triangular tube structure are as follows: the main chord is φ400×12, the web is φ159×10, the span is 31m, the height is 3 meters, and the section moment of inertia is 0.9×1011mm 4 , the weight per unit length including the track is 0.7 tons, and it can withstand a lifting load of 50 tons. It is the lightest product of the same type in the world. The nodes carrying the main girder adopt inclusive nodes, which grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com