Wheel bracket and method of fitting brake pads to the wheel bracket

A technology of wheel brackets and brake pads, which is applied to the parts of brakes, brakes, transportation and packaging, etc., which can solve the problems of sensor wear and large wear, and achieve the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

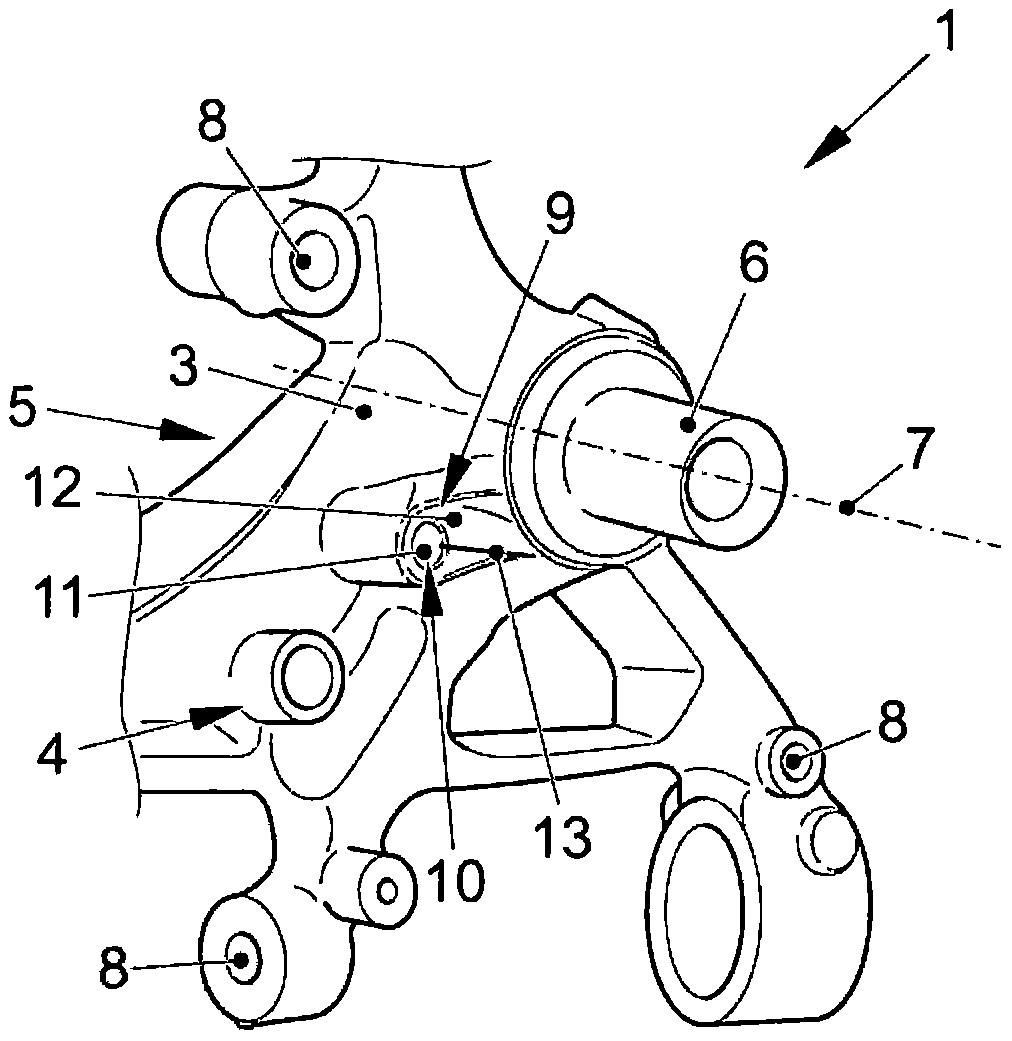

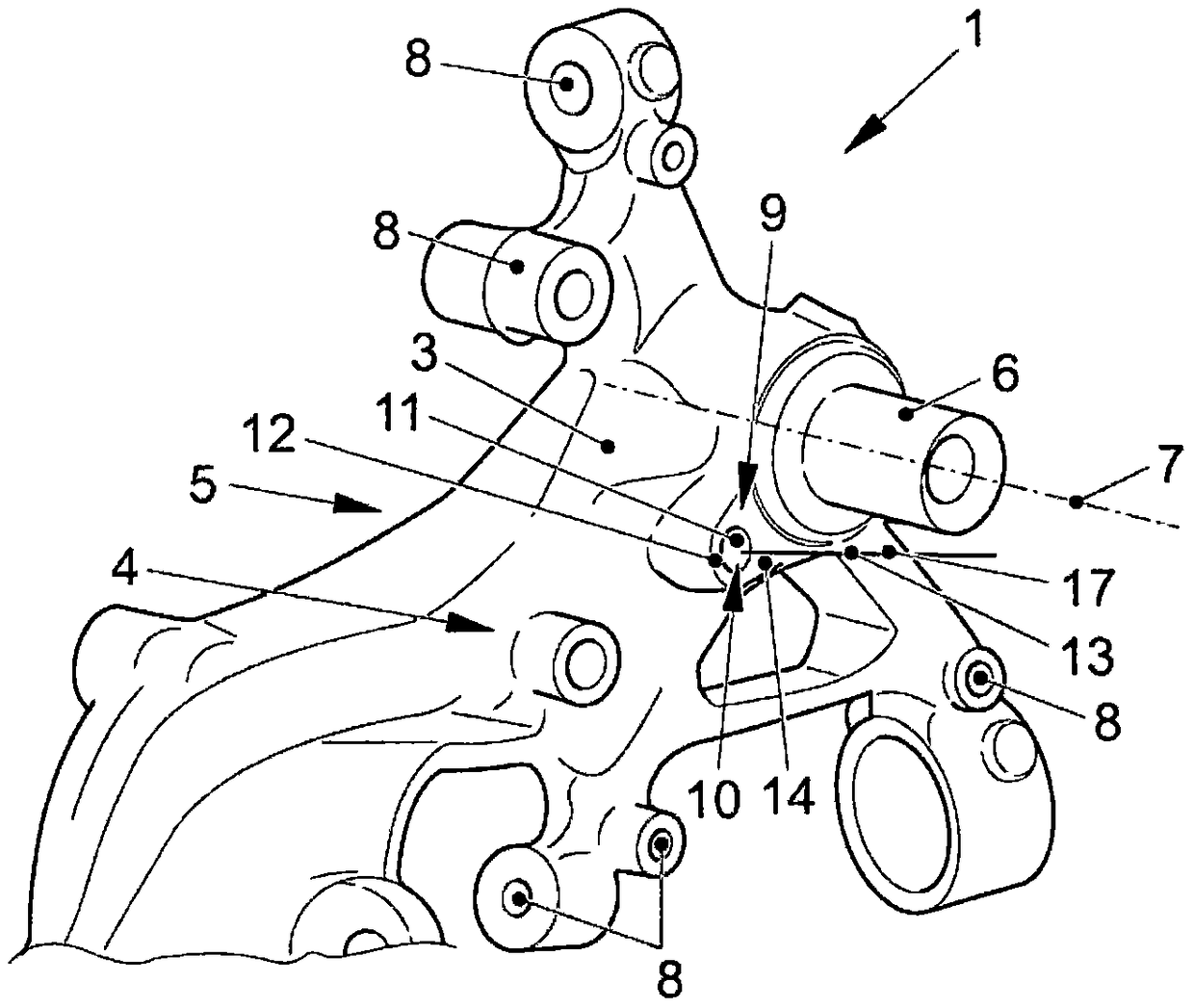

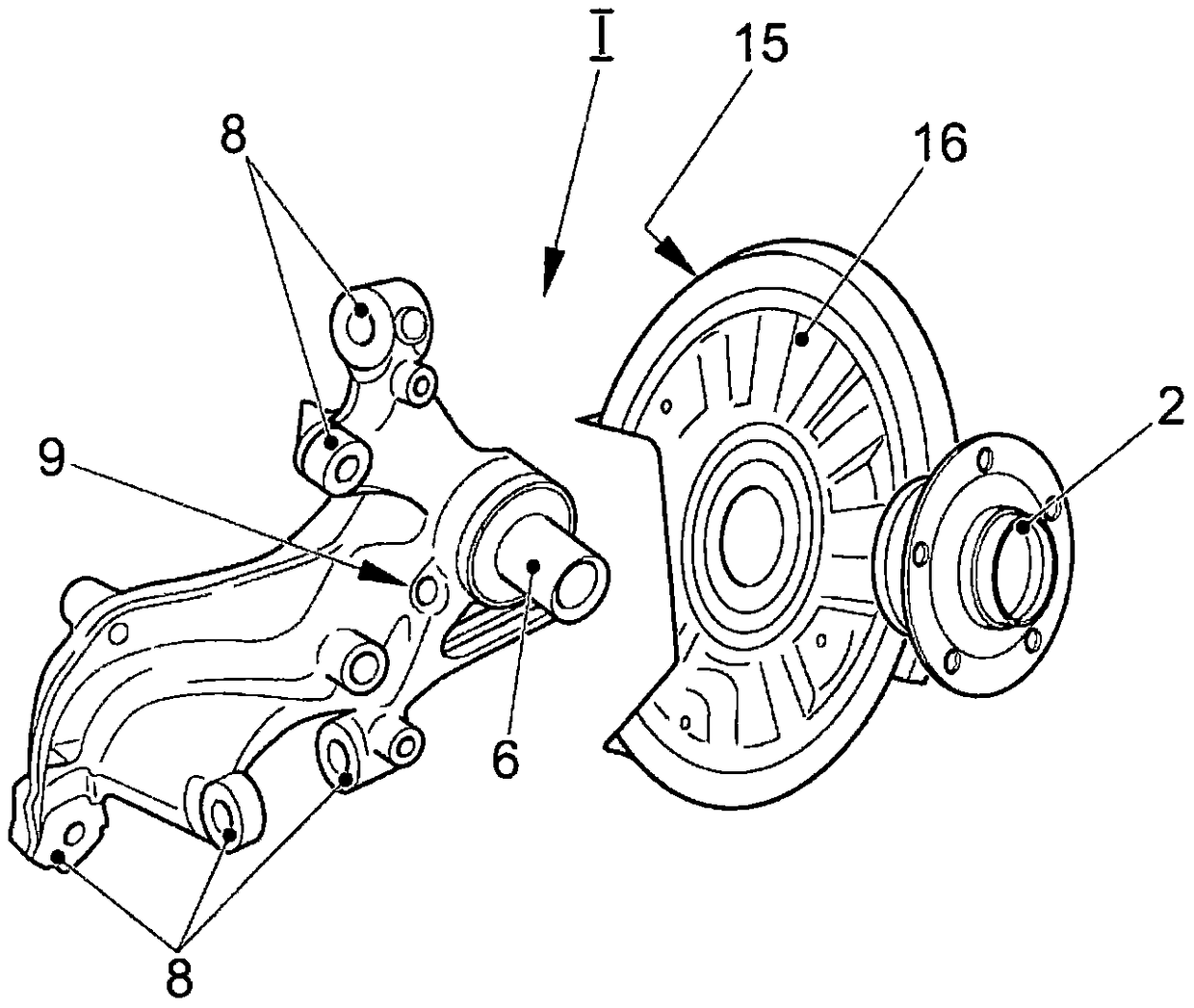

[0030] figure 1 A known wheel carrier 1 is shown, which has a body 3 with a wheel side 4 and a vehicle side 5 opposite this wheel side 4 and which cannot be seen in this view. Arranged on the wheel side is a substantially hollow-cylindrical receptacle 6 with a receptacle axis 7 , which is arranged substantially perpendicular to the body 3 . A wheel bearing 2 not shown in this illustration can be arranged on the receptacle 6 (see image 3). The wheel carrier 1 has a plurality of receptacles 8 which are designed to connect the wheel carrier 1 to the body of the motor vehicle by means of linkages. Arranged adjacent to the receptacle 6 is a sensor receptacle 9 which has a central through-opening 10 with an opening 11 and a receptacle surface 12 surrounding said opening. The opening 11 has a first alignment 13 which is formed substantially parallel to the receptacle axis 7 . The receiving surface 12 has rounded edges and is set back approximately toward the body 3 along the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com