Dispensing device with elastically driven mixer

A technology of mixing device and mixing element, which is applied in the directions of mixers with rotating containers, mixers with rotating stirring devices, shaking/oscillating/vibrating mixers, etc., can solve the deterioration and obstacles of cemented bone and prosthesis connection and other problems, to achieve the effect of triggering and applying humanized, low energy loss, simple and cheap design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

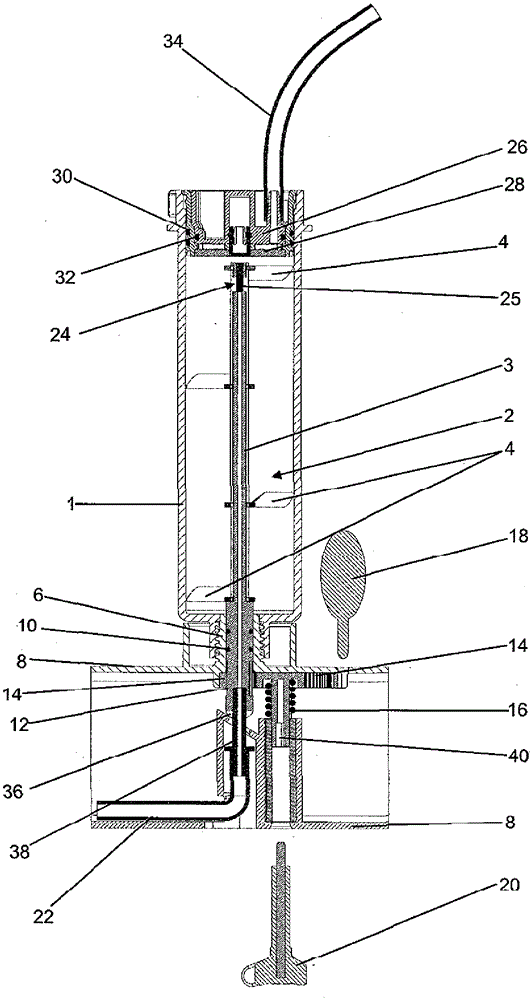

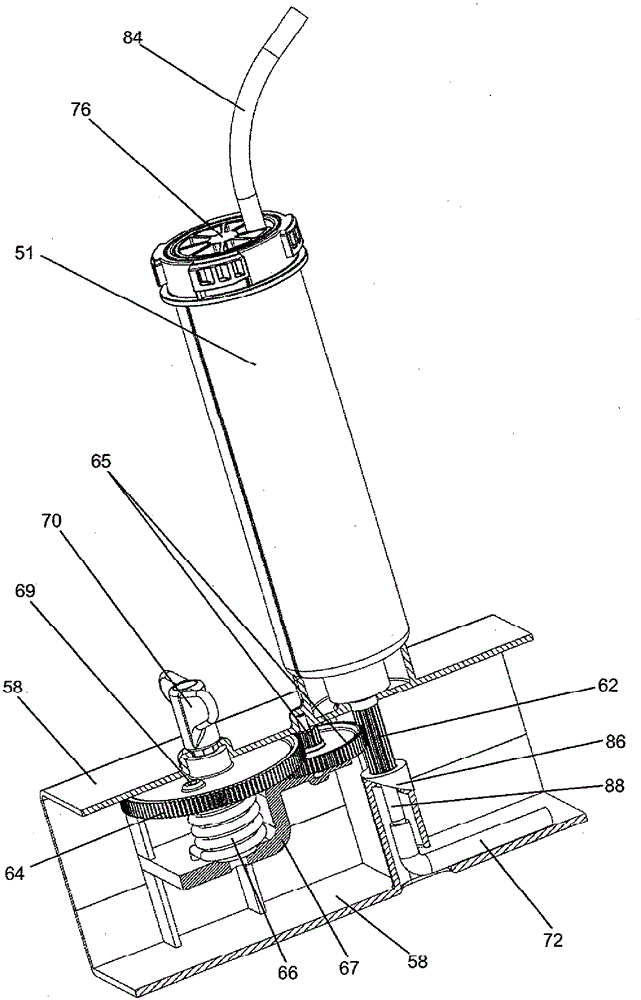

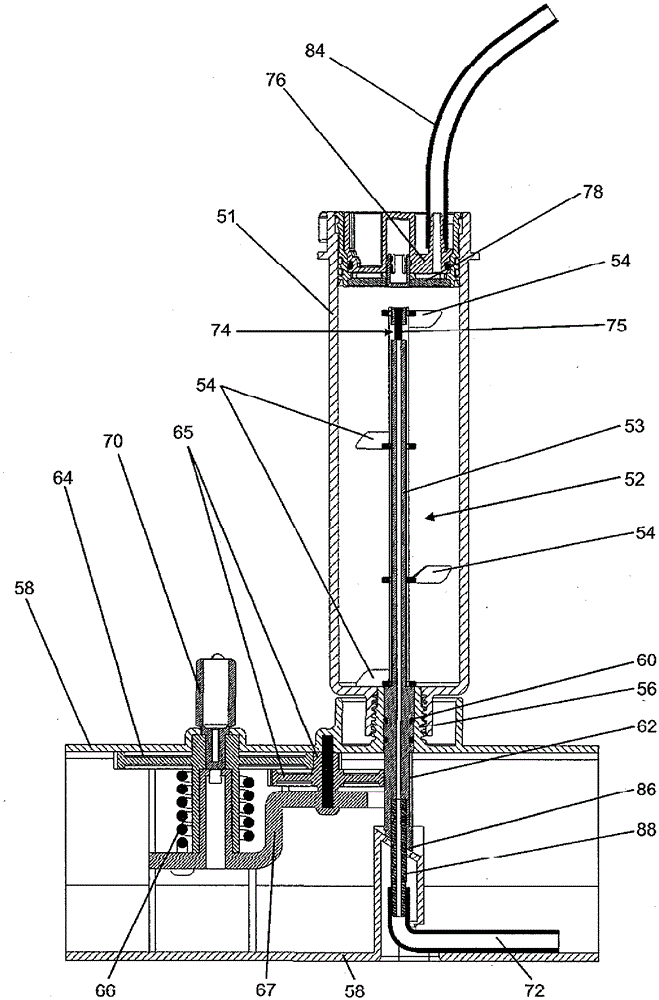

[0087] figure 1 and figure 2 a schematic cross-sectional view showing details of a vacuum mixing system according to the invention having a mixing device according to the invention for carrying out the method according to the invention, and image 3 A perspective schematic diagram of a partial section is shown. figure 1 and image 3 shows the locked state, and figure 2 The unlocked state is shown.

[0088] The vacuum mixing system has a cement cylinder 1 which consists of plastic material and which delimits a cylindrical mixing space 2 on its inner side. floor side distribution opening (in figure 1 and figure 2 , on the bottom) has a stirring shaft 3 guided through this opening, which is supported in a rotatable manner and has four mixing blades 4 attached thereto as mixing elements. The mixing blade 4 is connected to the mixing shaft 3 by means of a joint and can thus be placed against the mixing shaft 3 so that the mixing shaft 3 can be inserted into and pulled out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com