A battery box installation structure

A technology for installing structures and bags, which is applied in the direction of structural parts, battery pack parts, circuits, etc., can solve problems such as battery case falling off, installation ears breaking, affecting the stability and safety of battery power supply, etc., to enhance strength and prevent loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

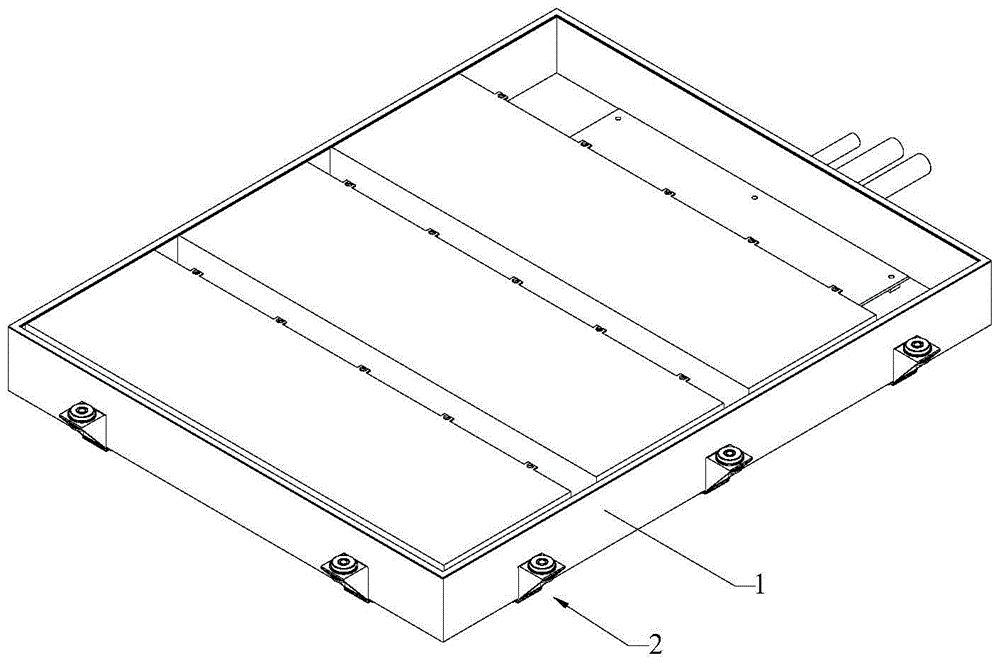

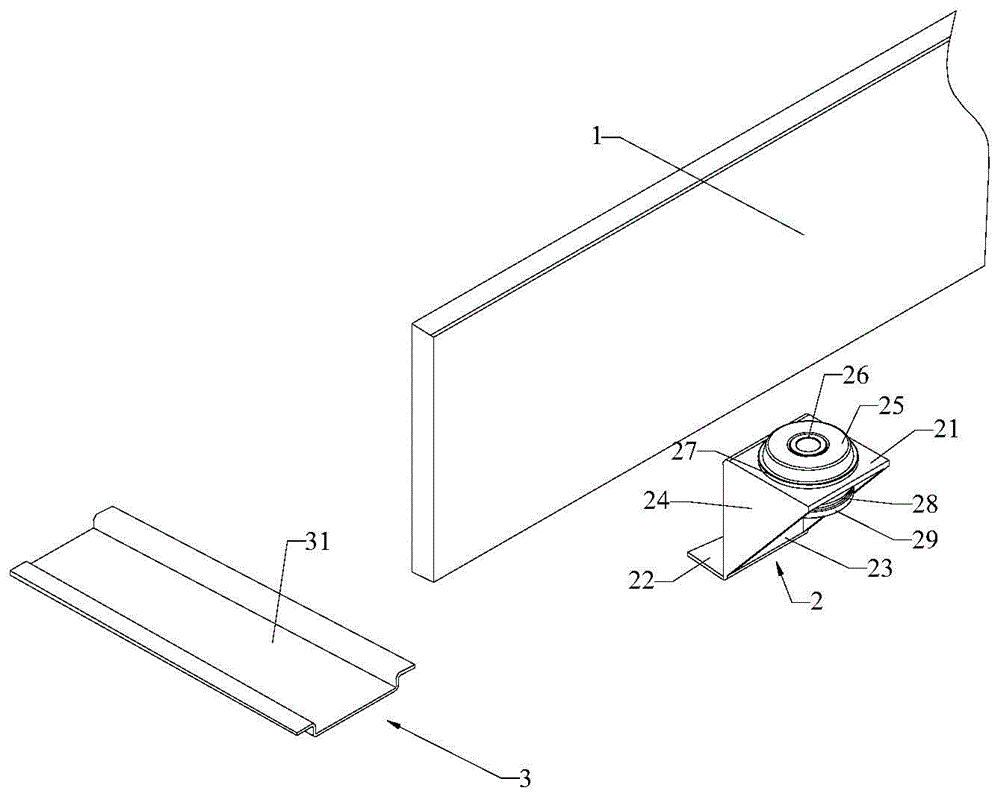

[0032] Please refer to Figure 1-3 , Embodiment 1 of the present invention is:

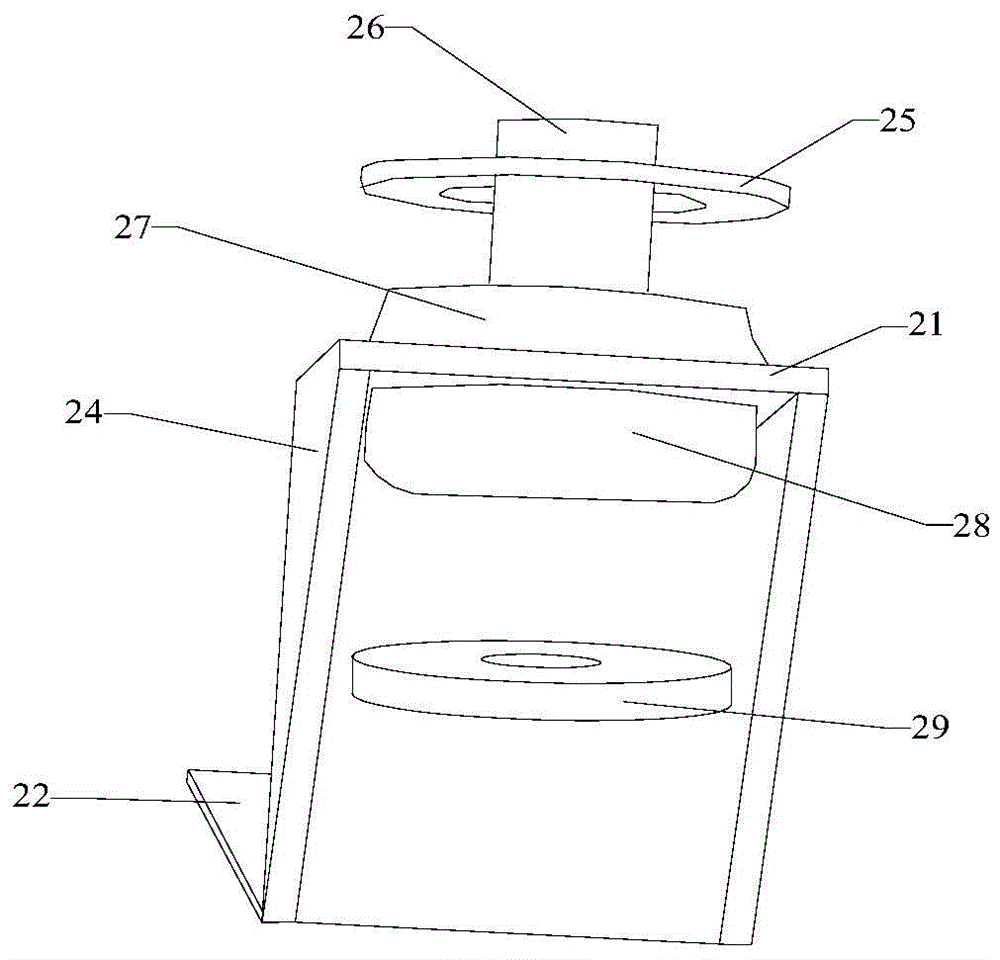

[0033] The invention provides a battery case installation structure, the battery case is a rectangular box; the battery case includes a bottom and a side 1; The mounting ear 2, the bolt 29, the first rubber pad 27, the second rubber pad 28, the bushing 26 and the annular flat pad 25 sleeved on the bushing 26; the mounting ear 2 is provided with a through hole , the annular flat pad 25 is arranged above the through hole, the first rubber pad 27 is arranged between the annular flat pad 25 and the through hole, the bolt 29 is arranged below the through hole, and the second The rubber pad 28 is arranged between the bolt 29 and the through hole; the bolt 29 passes through the second rubber pad 28, the through hole, the first rubber pad 27, the bushing 26, the annular flat pad 25 and the floor plate of the electric vehicle successively. The reinforced beams are fixedly connected;

[0034] The mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com