Thermoelectric module and manufacturing method thereof

A technology of thermoelectric modules and manufacturing methods, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, thermoelectric device node lead-out materials, etc., and can solve the problems of temperature sensing performance degradation, insignificant temperature difference, and limited film thickness and other problems, to achieve the effect of improving sensitivity, increasing electromotive force, and improving thermal electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

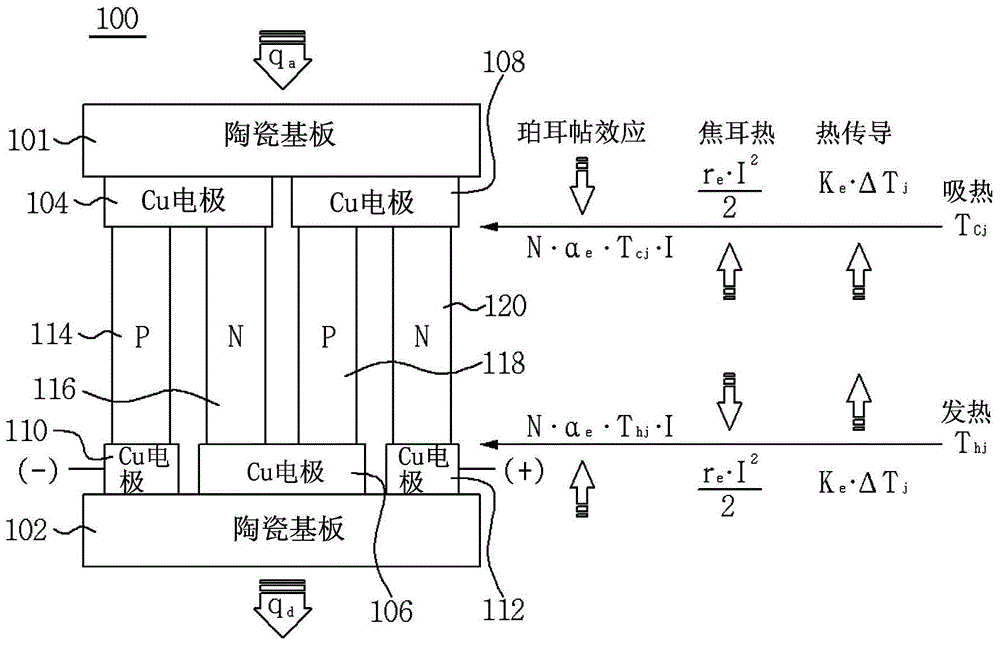

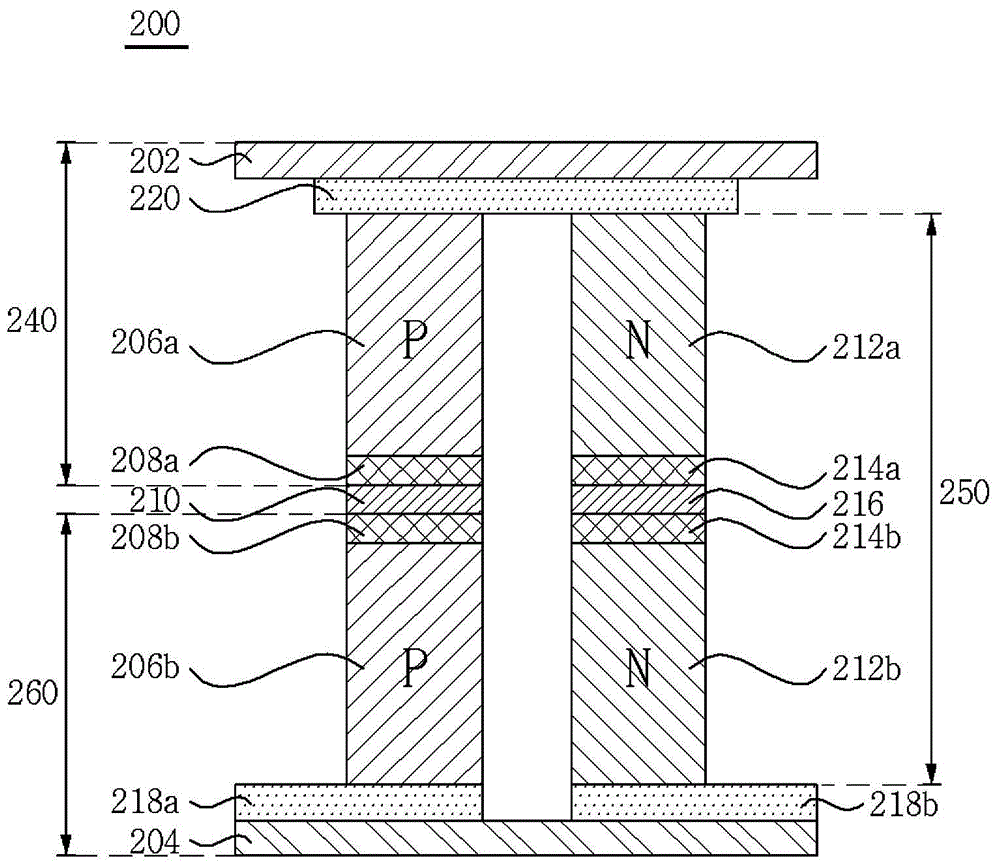

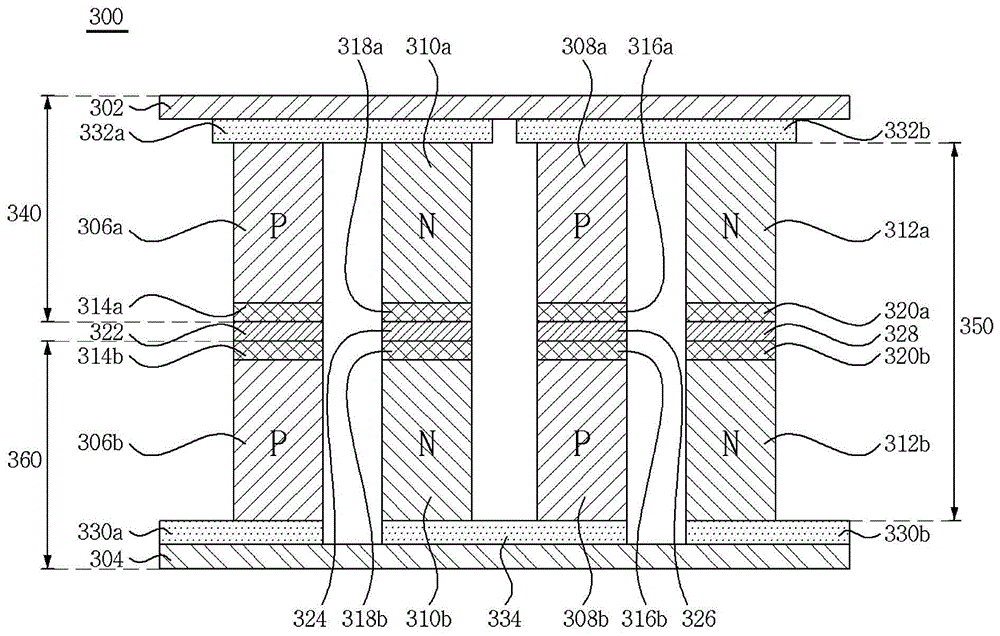

[0042] The purpose, specific advantages and novel features of the present invention will become more apparent through the following detailed description and preferred embodiments in conjunction with the accompanying drawings.

[0043] Before this, it should be explained that the terms or words used in this specification and claims should not be interpreted as generalized and dictionary meanings, but should be based on the inventor's ability to explain his invention in the best way. The principle of properly defining the concept of terms is interpreted as the meaning and concept in accordance with the technical idea of the present invention.

[0044] In this specification, when assigning reference numerals to components in the respective drawings, care should be taken to assign the same reference numerals as much as possible even if the same constituent elements are shown in different drawings.

[0045] In addition, terms such as "first", "second", "one side", and "another side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com