Improved oil cooler welding joints

A technology of welded joints and oil coolers, which is applied in the field of welded joints of improved oil coolers, can solve the problems of parts wear, piston melting, burns, etc., and achieves increased pressing and sealing, avoiding leakage and repairing, and pressing area Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

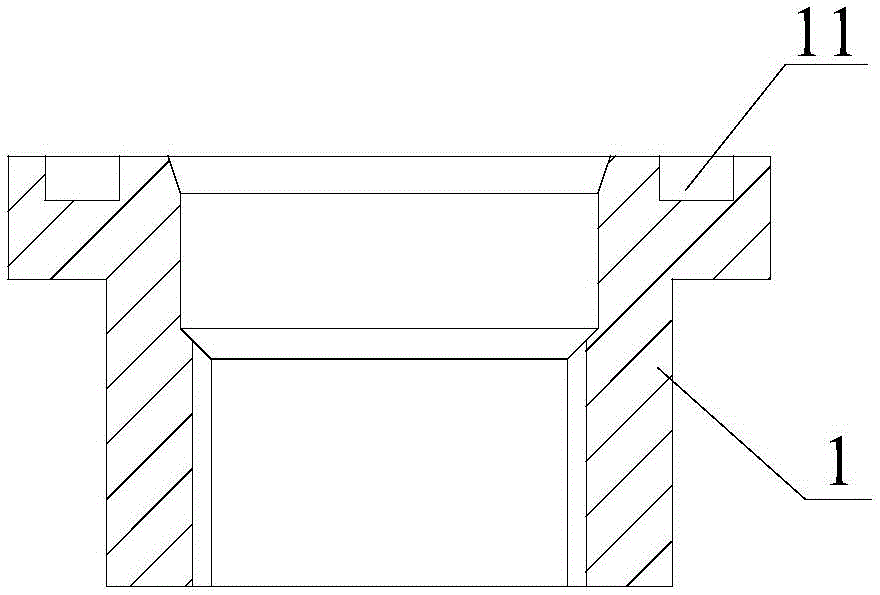

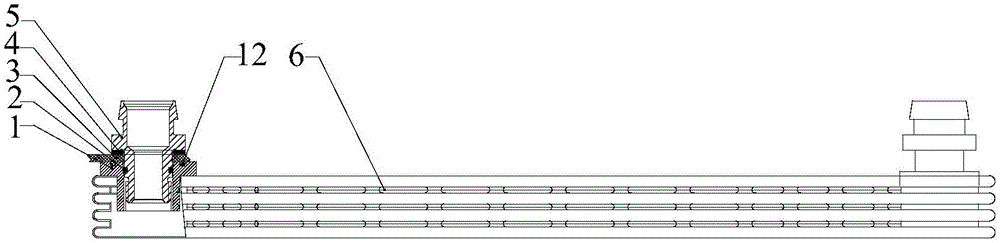

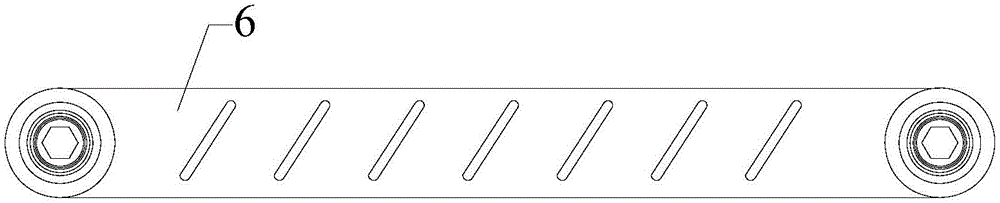

[0021] An improved oil cooler welded joint, its structure is as follows figure 1 As shown, it can be arranged on both sides of the oil cooler core 6 to connect the oil cooler core 6 and the water chamber 3, as shown in Figure 2-4 shown. The welded joint 1 is in plane contact with the inner side wall of the water chamber 3, and a sealing groove 11 is opened on the connection contact surface, and a sealing ring 12 is arranged in the sealing groove 11, thereby increasing the pressing area, and further making the pressing and sealing Correspondingly increased resistance, no product leakage will occur even under harsh working conditions, and can withstand high pressure.

[0022] The welded joint 1 is connected with the connecting pipe 5 by threads during application. A connecting pipe sealing ring 2 is also provided at the joint between the connecting pipe 5 and the welded joint 1 , and a combined sealing gasket 4 is provided at the contact surface between the connecting pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com