Drying room afterheat recycling device

A technology of waste heat recovery device and heat exchange device, which is applied in drying, heat exchanger type, indirect heat exchanger, etc., can solve the problems of heat energy not being used effectively, failing to be recycled, heat energy loss, etc., To achieve the effect of simple structure, convenient device cleaning and maintenance, and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

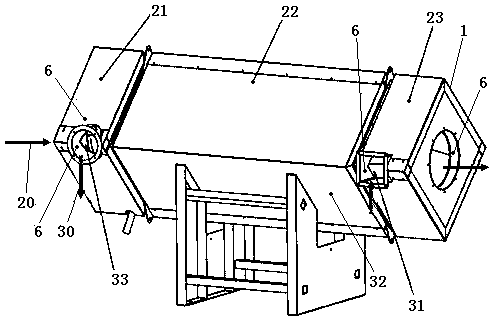

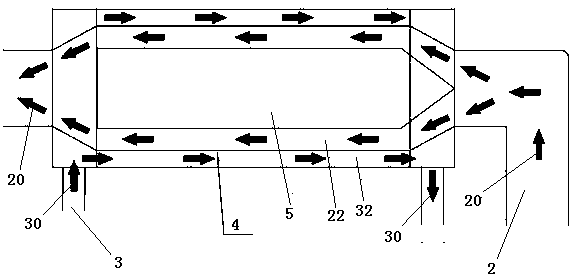

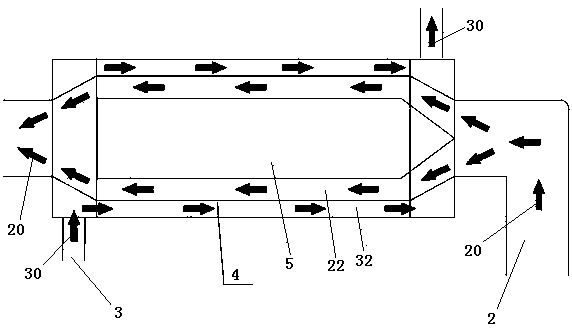

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 A drying room waste heat recovery device shown includes a heat exchange body, which is characterized in that: the heat exchange body includes a shell 1 and a fresh air channel 3 and a hot exhaust gas channel 2 in the shell 1, and the fresh air channel 3 and the hot exhaust gas channel 2 are provided with a heat exchange device 4, which absorbs the heat of the exhaust gas flowing through the hot exhaust gas channel 2 by using the principle of heat exchange.

[0018] Further, the hot exhaust gas passage 2 sequentially includes a hot exhaust gas tank 21 , a heat exchange area 22 and a cooled exhaust gas tank 23 according to the hot exhaust gas flow direction 20 ; the fresh cold air flow direction 30 is opposite to the hot exhaust gas flow direction 20 .

[0019] Further, the hot exhaust gas channel 2 in the heat exchange area 22 is located at the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com