Method for preparing high-strength aluminum alloy wire for novel energy-saving wire

An aluminum alloy wire, high-strength technology, applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve the problems that the strength cannot meet the requirements, the conductivity cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

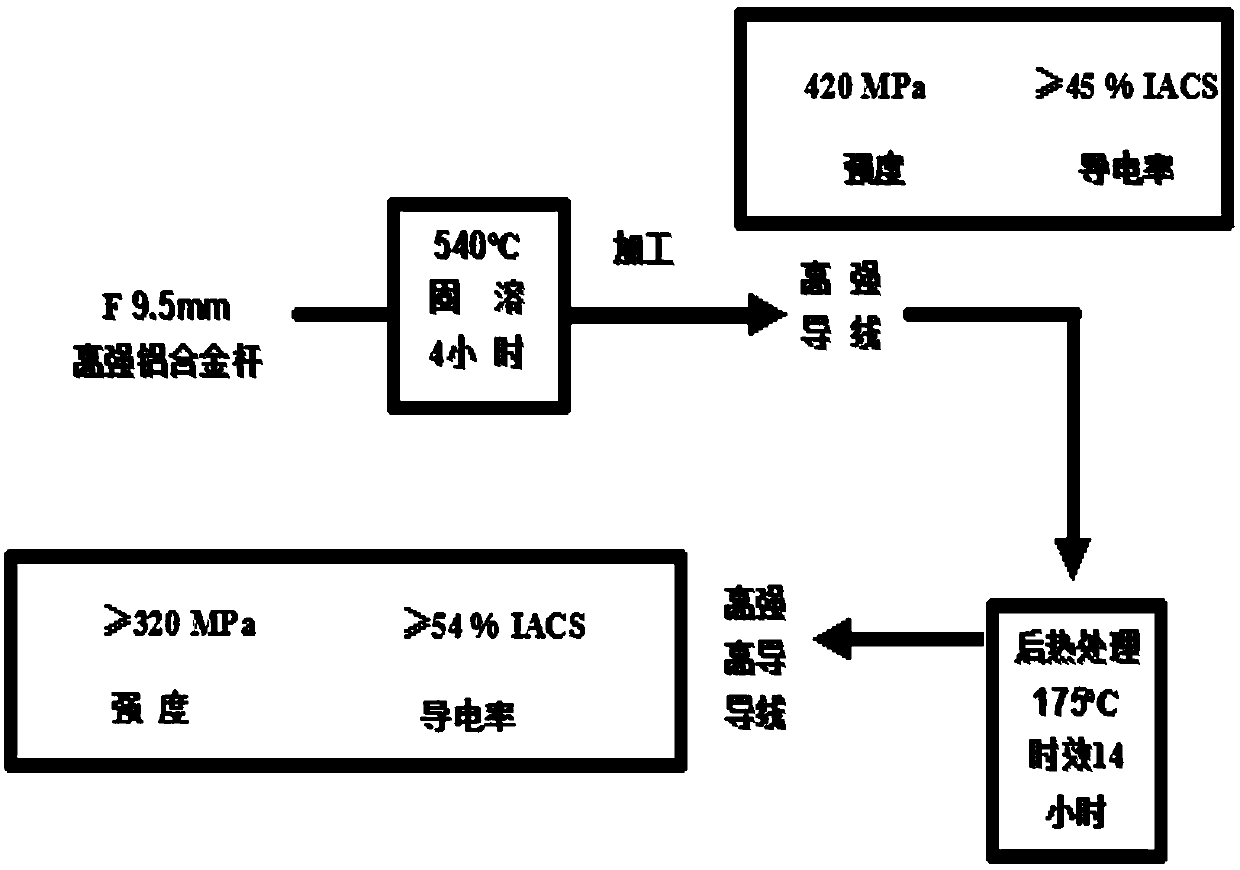

[0094] The preparation method of the present invention specifically comprises the following process steps:

[0095] (1) Heat treatment process of high-strength aluminum rod:

[0096] That is, pre-solution treatment. First, a hot-rolled aluminum rod with a diameter of 9.5 (±0.1) mm is selected, and its composition range is: Si: 0.57-0.74%; Fe: 0.2-0.3%; Cu: 0.01-0.03%; Mg: 0.63-0.7%; Zn: ≦0.05%; Ti:≦0.015%; the micro-Vickers hardness range of the aluminum rod is 60-70HV.

[0097] Secondly, randomly take radial sections at 3 places on the original aluminum rod as samples, and the Brinell hardness range: HBS: 100-200.

[0098] Finally, perform heat treatment on the original aluminum rod: the temperature is 530oC-540oC, the high-strength aluminum alloy wire enters the heat treatment furnace for 5 minutes to start timing, and the holding time is 3.8 hours to 4.2 hours. The sample taken out is not allowed to stay in the air. Control at 20oC-25oC.

[0099] (2) High-strength alumi...

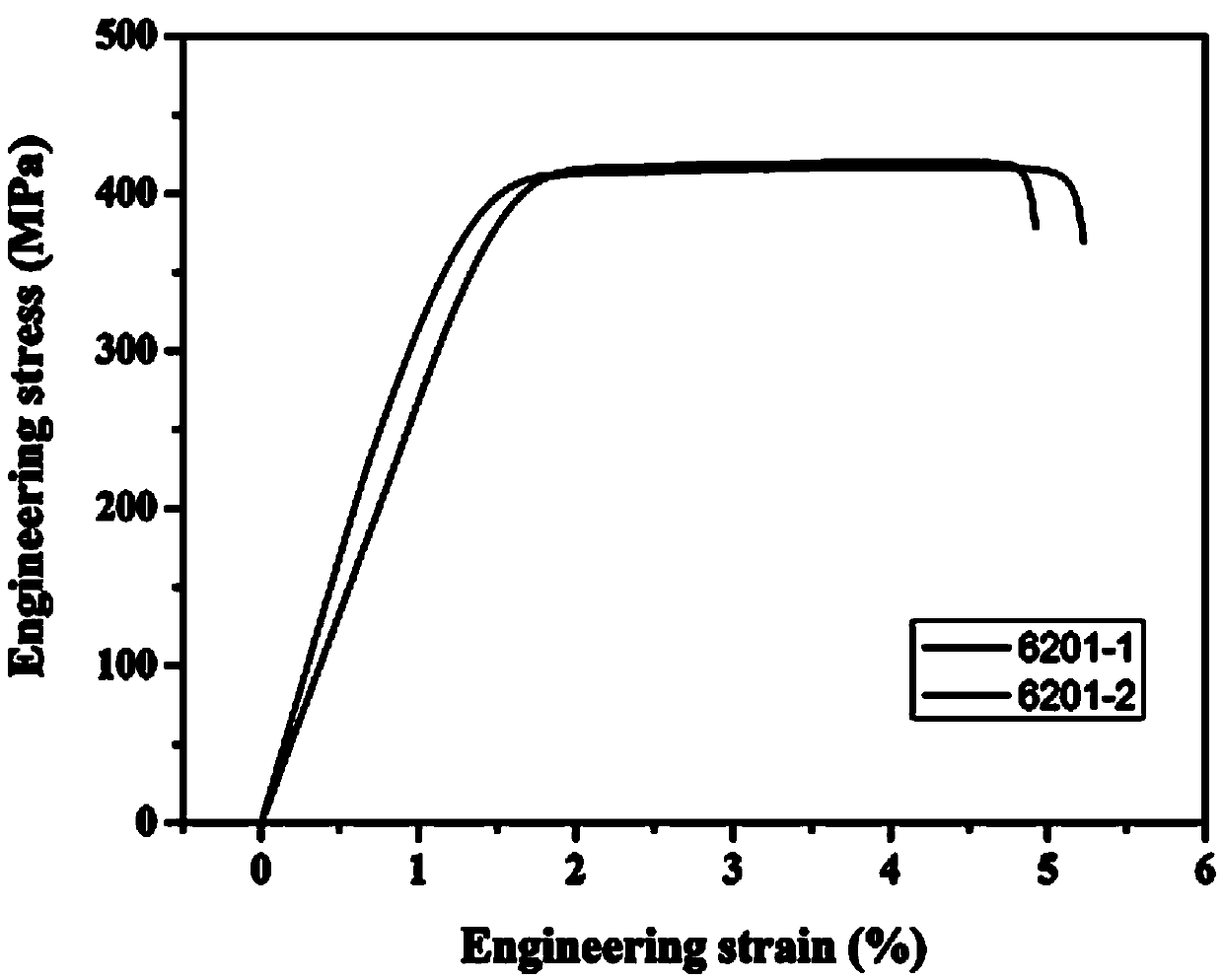

Embodiment 1

[0122] A method for preparing a new energy-saving high-strength aluminum alloy wire for wires, specifically comprising the following process steps:

[0123] (1) Heat treatment process of high-strength aluminum rod:

[0124] That is, pre-solution treatment. First, a hot-rolled aluminum rod with a diameter of 9.5mm is selected, and its composition range is: Si: 0.64%; Fe: 0.25%; Cu: 0.02%; Mg: 0.68%; Zn: 0.02%; Ti: 0.015%.

[0125] Secondly, randomly take three radial sections on the original aluminum rod as samples, and the micro-Vickers hardness range: 60HV.

[0126] Finally, heat treatment is carried out on the original aluminum rod: the temperature is 540oC, the high-strength aluminum alloy wire enters the heat treatment furnace for 5 minutes to start timing, and the holding time is 4 hours.

[0127] (2) High-strength aluminum wire drawing process:

[0128]That is, cold drawing process. The production of high-strength aluminum wire with a diameter of 3mm has been drawn t...

Embodiment 2

[0148] A method for preparing a new energy-saving high-strength aluminum alloy wire for wires, specifically comprising the following process steps:

[0149] (1) Heat treatment process of high-strength aluminum rod:

[0150] That is, pre-solution treatment. First, a hot-rolled aluminum rod with a diameter of 9.6mm is selected, and its composition range is: Si: 0.57%; Fe: 0.2%; Cu: 0.01%; Mg: 0.63%; the micro-Vickers hardness range of the aluminum rod is 65HV.

[0151] Secondly, randomly take radial sections at 3 places on the original aluminum rod as samples, and the Brinell hardness range: HBS: 150.

[0152] Finally, heat treatment is carried out on the original aluminum rod: the temperature is 530oC, the high-strength aluminum alloy wire enters the heat treatment furnace for 5 minutes to start timing, and the holding time is 3.8 hours.

[0153] (2) High-strength aluminum wire drawing process:

[0154] That is, cold drawing process. The production of high-strength aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com