Product positioning and clamping mechanism

A positioning clamping and product technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of uncoordinated movements of multiple power sources, inaccurate positioning, complex structures, etc., and achieve coordinated and synchronized actions, improved efficiency, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

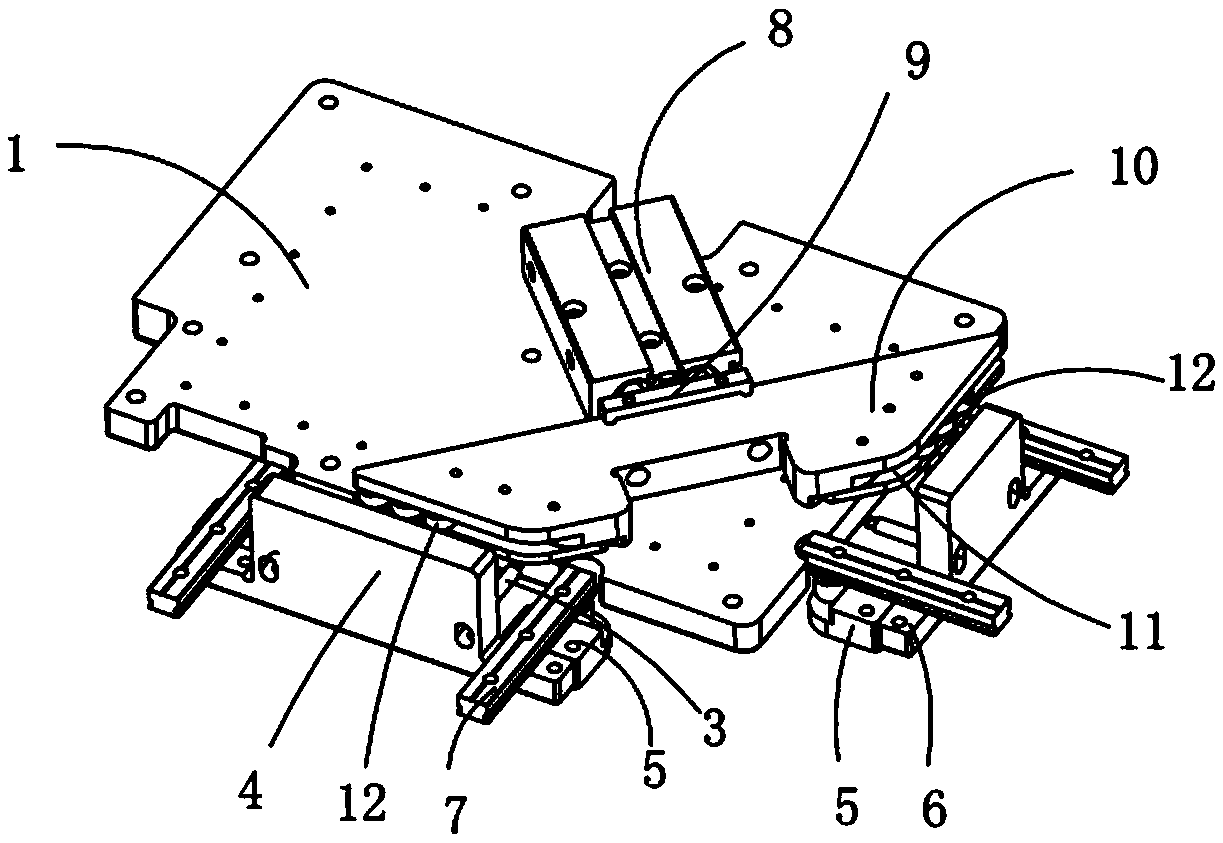

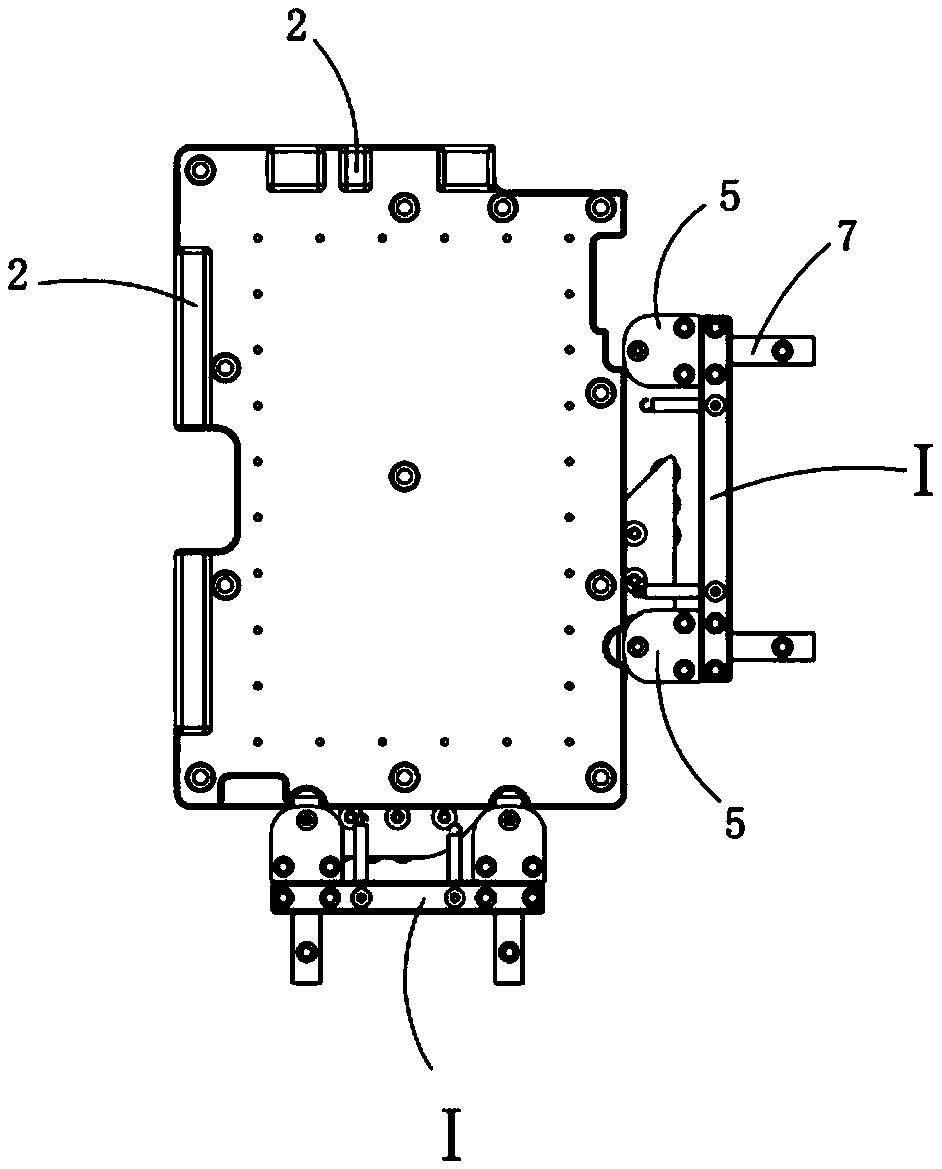

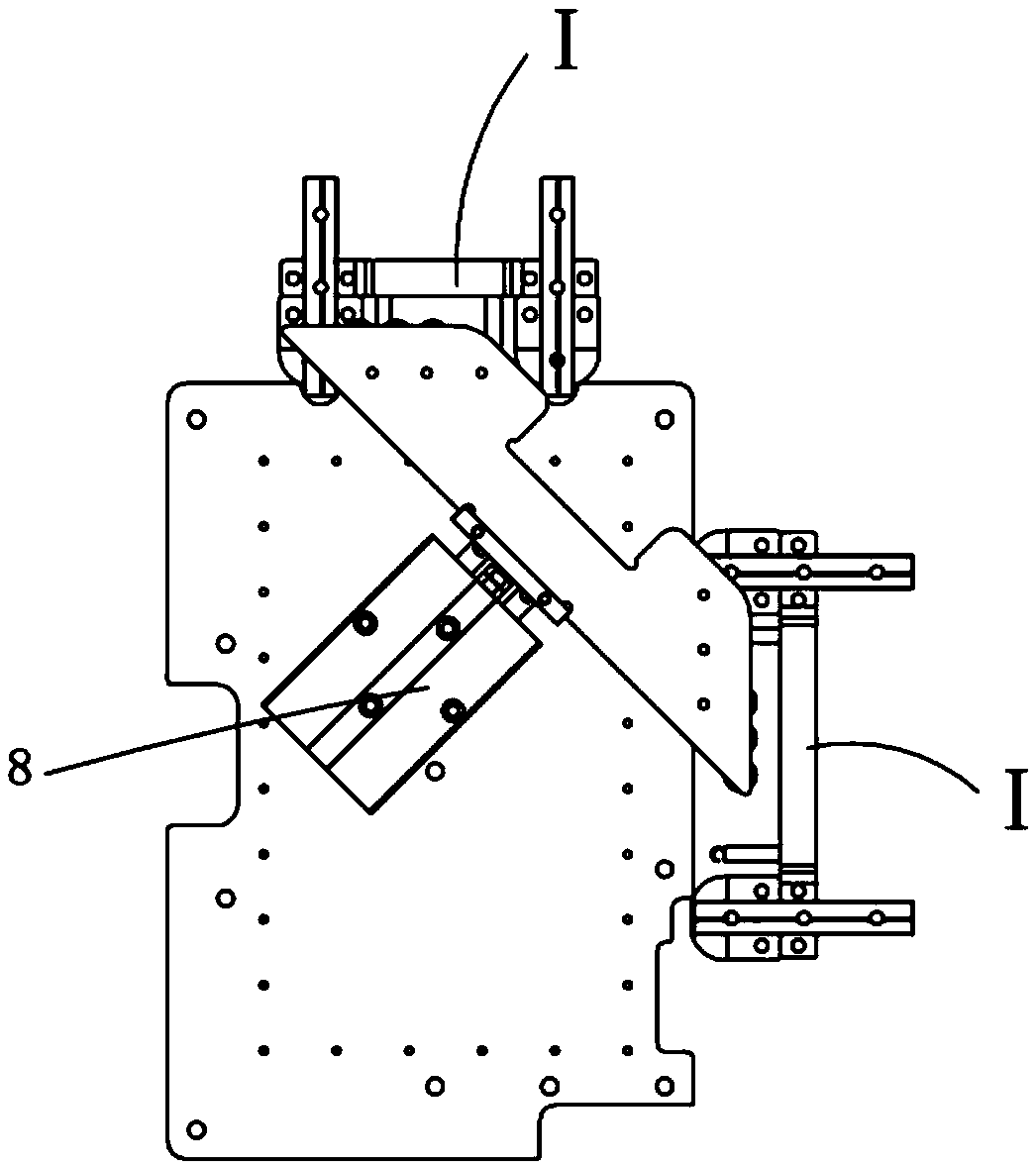

[0018] Examples, see attached Figure 1~3 , a product positioning clamping mechanism, including a bearing plate 1, the upper part of the bearing plate is provided with a rib 2, and the rib is located at the upper left side or the upper rear side of the bearing plate.

[0019] The front part and the right part of the bearing plate are respectively provided with an elastic mechanism I, and the elastic mechanism includes a spring 3, a sliding block 4 and a collet 5, and the sliding block is installed on the front side or the right side of the bearing plate through a spring; The sliding block is a convex structure, and chucks are respectively installed at the positions of flanges 6 on both sides of the convex structure, and the lower bottom surface of the chuck is higher than the upper surface of the loading plate, and the product is placed on the loading plate, and the chuck can Product clamping;

[0020] The bottom of the sliding block is mounted on the guiding mechanism; the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com