Automatic cleaning device of milling roller

An automatic cleaning and rolling roller technology, applied in the energy field, can solve the problems of manual cleaning, scrapping of pole pieces, inability to effectively clean the rolling roller, etc., and achieve the effect of improving work efficiency, reducing production costs and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

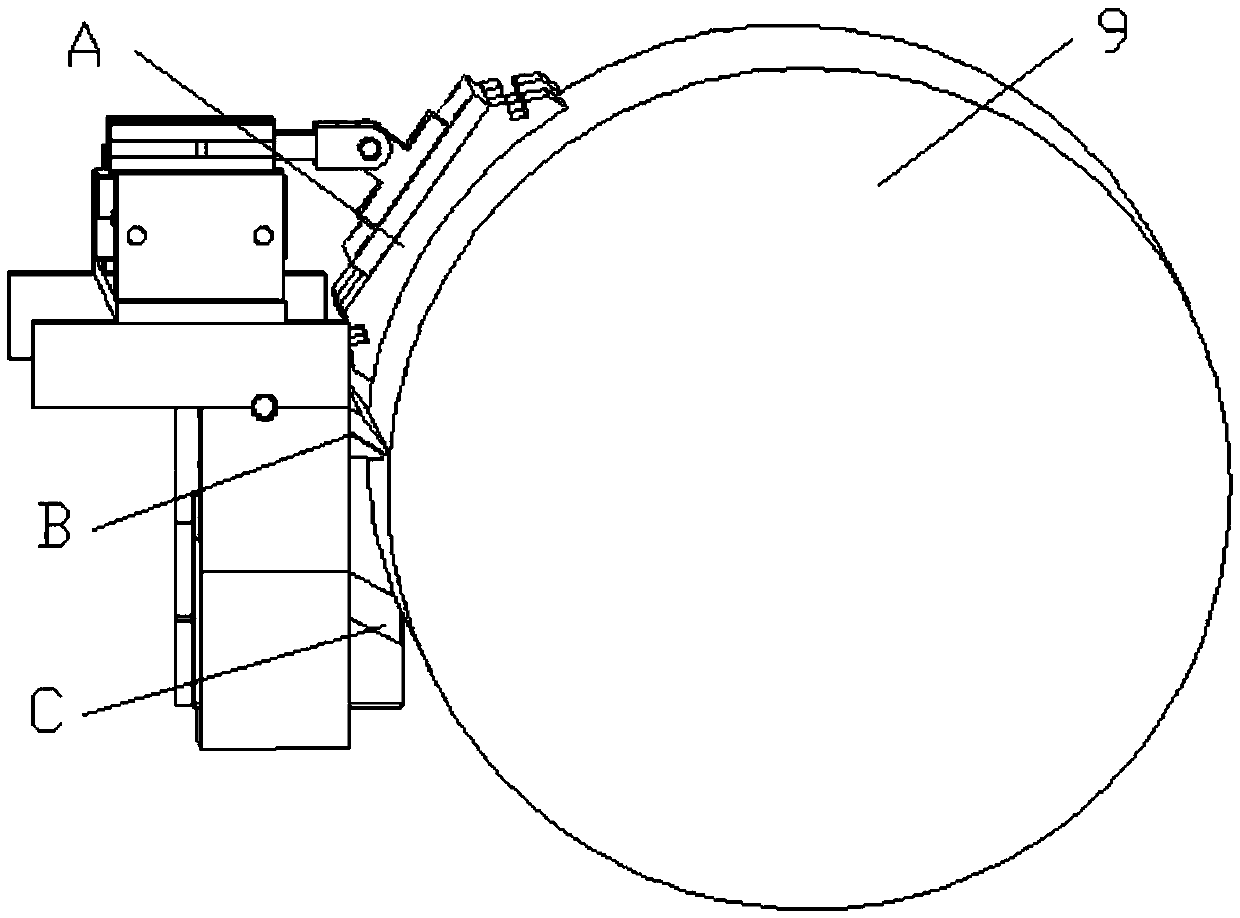

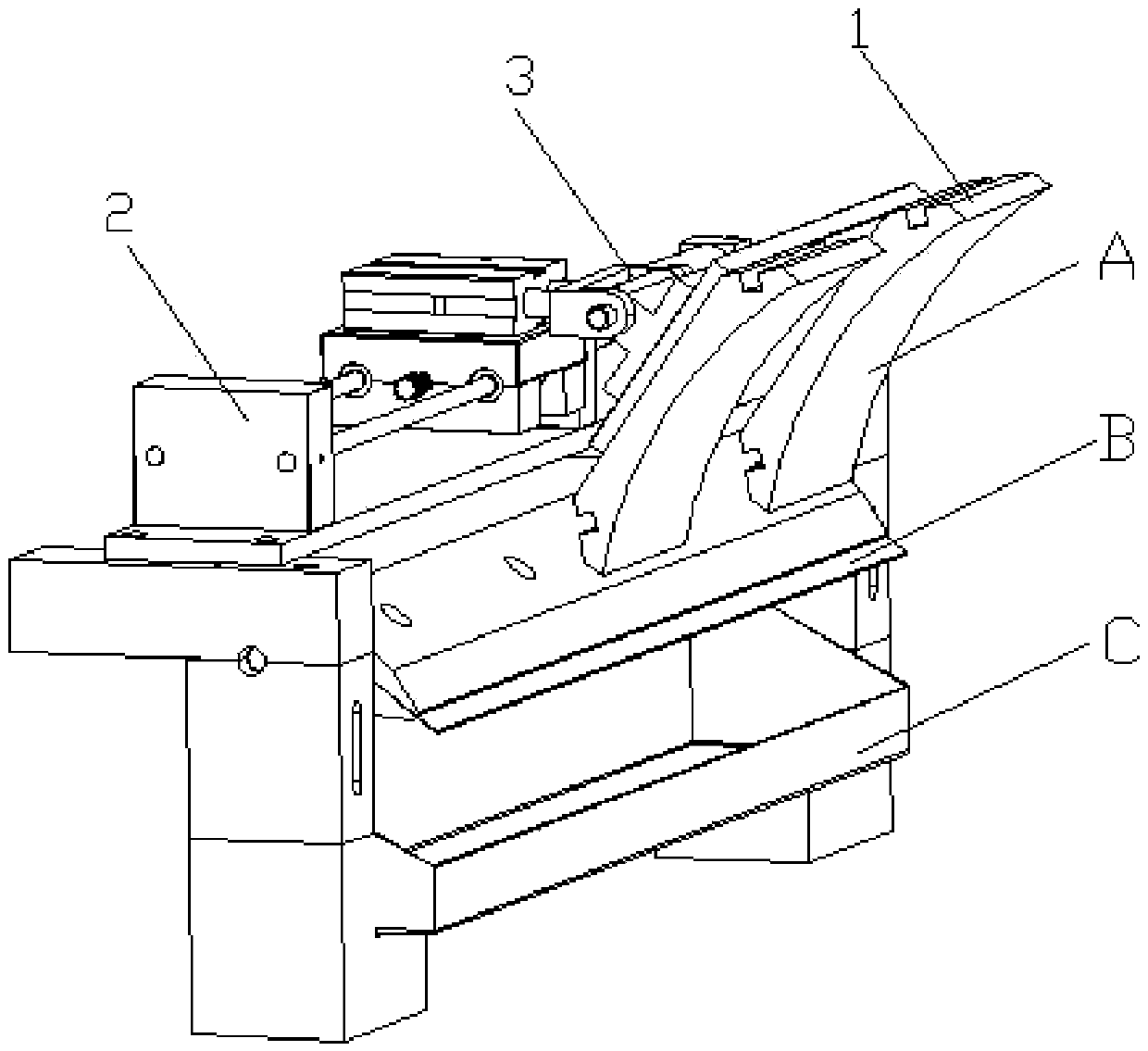

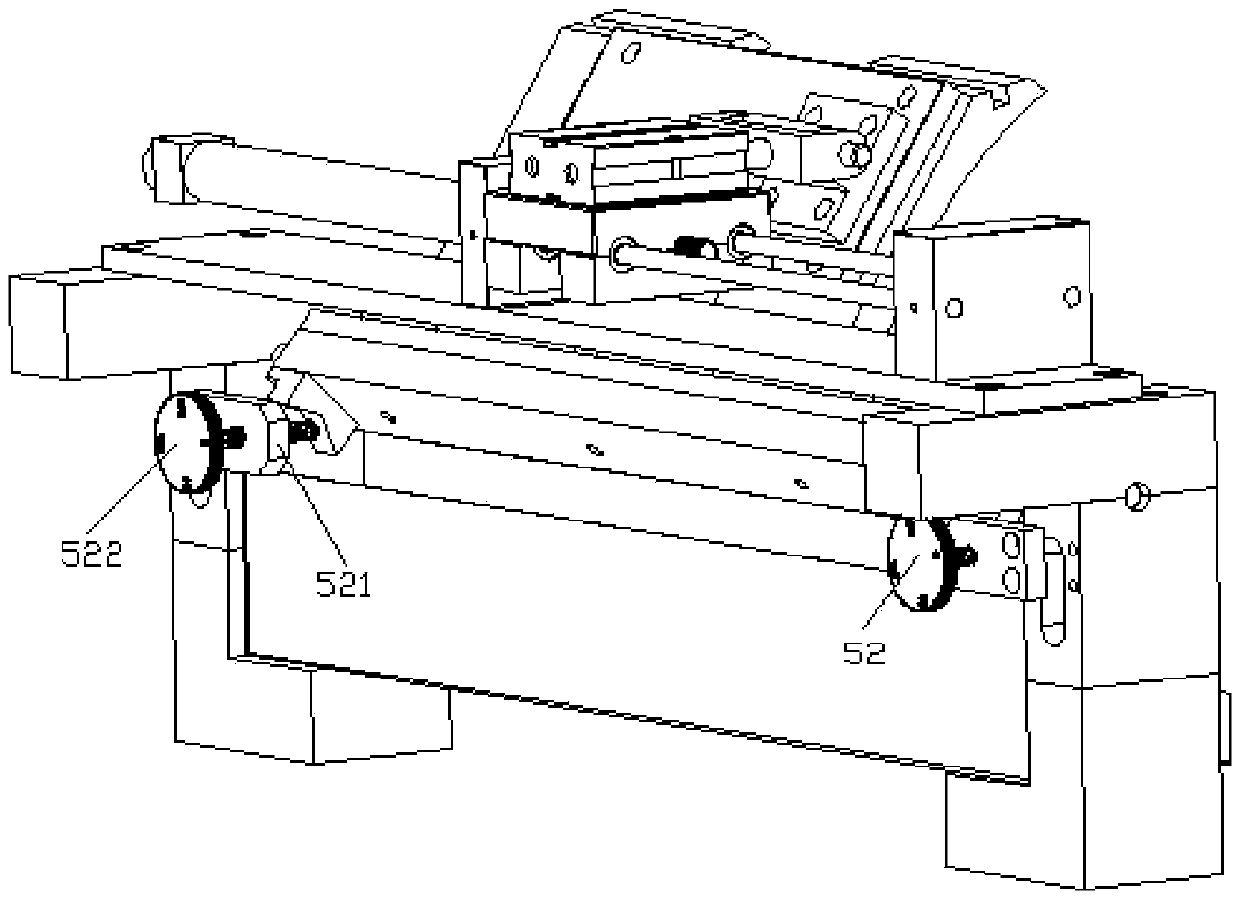

[0039] Such as Figure 1-7 As shown, the automatic cleaning device for the rolling roller of this embodiment, the cleaning device is used in conjunction with the rolling machine, and includes a roller rubbing device A and a roller scraping device B arranged sequentially from top to bottom;

[0040] The roller rubbing device A includes a scraping unit 1, a cylinder unit 2 and a connecting piece 3 between the scraping unit and the cylinder unit, the scraping unit 1 includes a cleaning brush 11 and a cleaning brush fixing plate 12, Several cleaning brushes 11 are fixedly mounted on the cleaning brush fixing plate 12;

[0041] The cylinder unit 2 includes a roller rubbing cylinder 21 for controlling the left and right movement of the scraping unit 1 and a positioning cylinder 22 for controlling the forward and backward movement of the scraping unit 1 , and the positioning cylinder 22 passes through the connecting member 3 Connected with the cleaning brush fixing plate 12, the rol...

Embodiment 2

[0063] Such as Figure 1-8 As shown, the automatic cleaning device for rolling rollers in this embodiment, which is used in conjunction with the rolling machine, includes a roller rubbing device A, a scraping roller device B and a dust collection device C arranged sequentially from top to bottom;

[0064] The roller rubbing device A includes a scraping unit 1, a cylinder unit 2 and a connecting piece 3 between the scraping unit and the cylinder unit, the scraping unit 1 includes a cleaning brush 11 and a cleaning brush fixing plate 12, Several cleaning brushes 11 are fixedly mounted on the cleaning brush fixing plate 12;

[0065] The cylinder unit 2 includes a roller rubbing cylinder 21 for controlling the left and right movement of the scraping unit 1 and a positioning cylinder 22 for controlling the forward and backward movement of the scraping unit 1 , and the positioning cylinder 22 passes through the connecting member 3 Connected with the cleaning brush fixing plate 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com