Potato classifying and bagging device

A bagging device and potato technology, which is applied in grading, solid separation, packaging food and other directions, can solve the problems of high work intensity, low work efficiency, high production cost, etc., to overcome the problems of high work intensity, high work efficiency and high work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

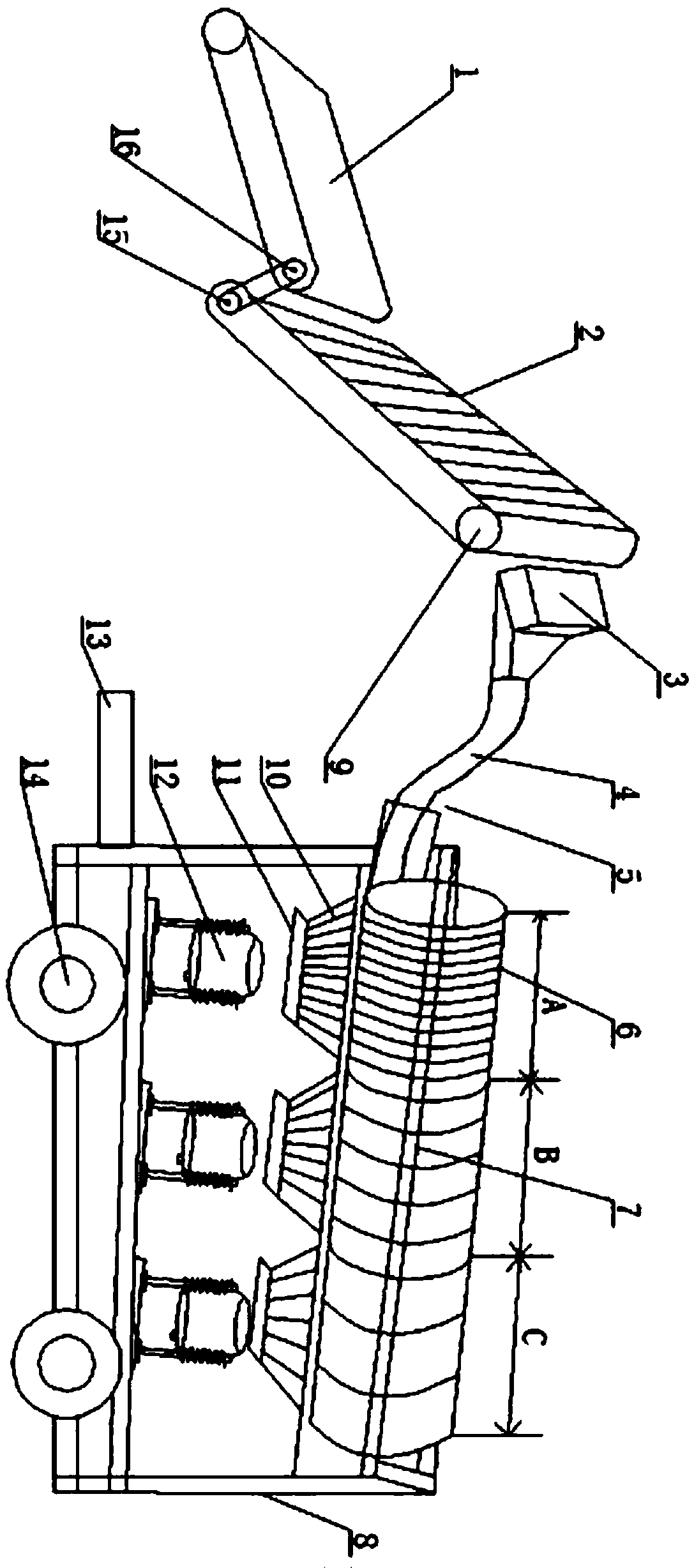

[0028] Further illustrate the present invention below in conjunction with accompanying drawing.

[0029] like figure 1 As shown, a potato grading and bagging device includes a lifting device, a rolling grading screen, a material receiving device, and the lifting device is connected with a potato harvesting device. The potato harvesting device is an existing equipment, which is connected with a tractor. The headland rises or falls, and the rolling grading screen is set on the frame. The frame is in contact with the ground through four wheels and never leaves the ground. Therefore, it is actively pulled with the harvesting device at the front end. Will not have an impact.

[0030] The distance between the rolling grading screen and the lifting device is suitable for turning without collision. The power of the rolling grading device is provided by the tractor. The two ends or one end of the transmission column for power transmission are connected by universal joints. The gradin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com