Split type soybean milk machine

A soymilk maker, split-type technology, applied in beverage preparation devices, household utensils, applications, etc., can solve the problems of misalignment between the machine head and the cup body, small bearing area, easy deviation of the machine head, etc., and achieve force-bearing Balanced, large heating area, solve the effect of unstable machine head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention will be further described:

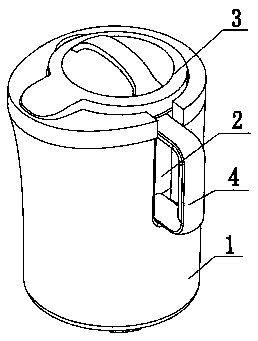

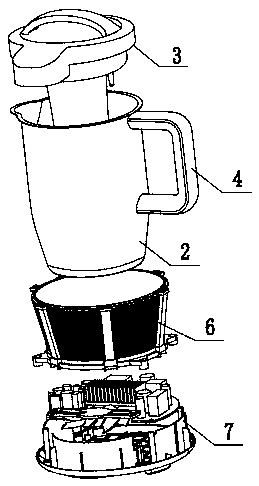

[0040] A split type soybean milk machine, comprising a machine base 1, a cup body 2 and a machine head 3, the machine head is set on the machine base, the cup body is wrapped around the inside of the machine base, and the cup body is provided with a portable handle 4, The machine base is provided with an avoidance gap 5 matched with the handle; the machine base includes a bottom shell 7, an outer shell 10, an upper shell 8 and an inner support 9, the lower end of the outer shell 10 is connected with the bottom shell 7, and the inner support 9 is connected with the upper shell 8. The outer casing 10 is connected; the inner support member 9 is provided with a U-shaped notch 11 matching with the evacuation gap, the upper ends of the U-shaped notch 11 are provided with a fixed through hole 12, and the upper shell is provided with a evacuation gap. The matching U-shaped opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com