Full-hydraulic fast switching trimming device

A technology of fast switching and trimming devices, applied in cutting tools, cutting equipment, gardening, etc., can solve the problems of inability to achieve 360° rotating motion of the tool holder, reduce operation reliability, unstable center of gravity of the mobile platform, etc., and reduce labor costs. , improve comfort, and increase the effect of cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

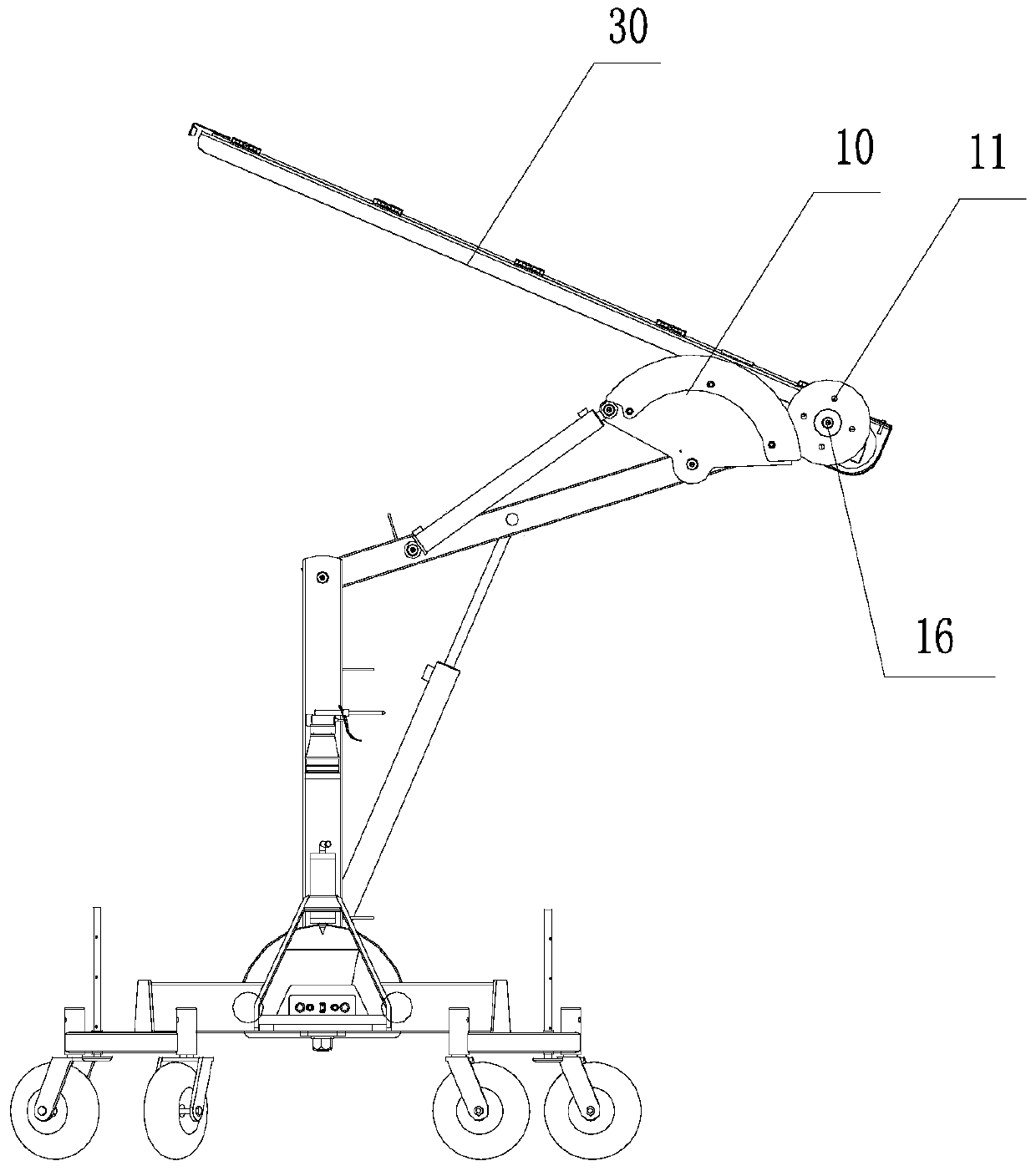

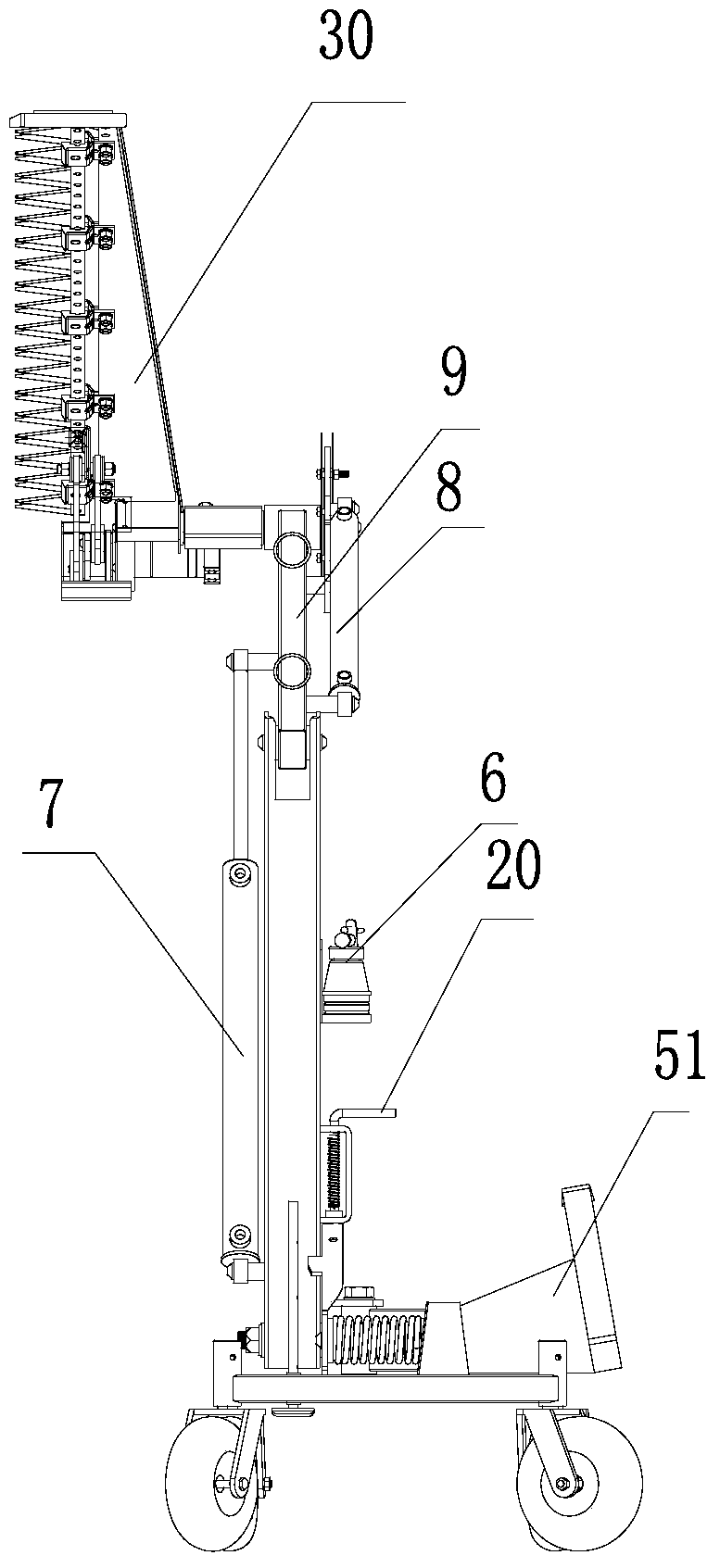

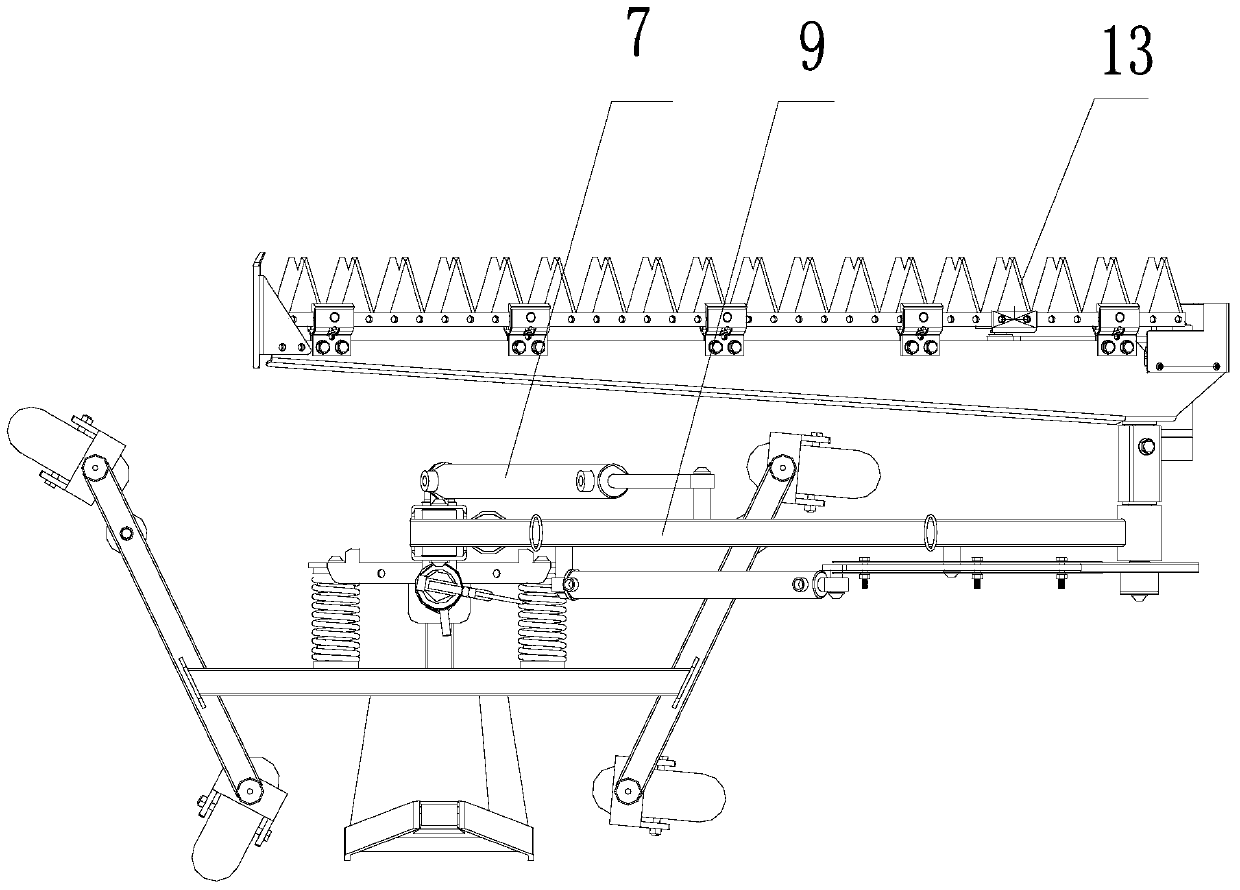

[0037] The present invention as Figure 1-13 As shown, including traveling mechanism, lifting mechanism, rotating mechanism and cutting components,

[0038] Described walking mechanism comprises crossbeam 2 and a pair of support 27, and a pair of support 27 is symmetrically arranged on the two ends of described crossbeam 2, and the two ends of described support 27 are respectively connected with roller 1; The A-frame 51 is provided with an oil circuit 52 for work;

[0039] Described elevating mechanism comprises main beam 4, cantilever beam 9 and hydraulic cylinder one 7, and described main beam 4 is connected on the crossbeam 2 of described walking mechanism by adapting mechanism, and described cantilever beam 9 is hinged on described main beam 4 , the hydraulic cylinder one 7 is respectively connected to the main beam 4 and the cantilever beam 9;

[0040] Described adaptation mechanism comprises support plate 3, U-shaped frame 14 and a pair of spring 15, and described supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com