Deodorization grain threshing machine

A thresher and grain technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of many sundries, unclean grain threshing, etc., and achieve the effects of clean threshing, elimination of odor, and fast threshing speed

Inactive Publication Date: 2016-03-02

GUILIN UNIV OF AEROSPACE TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The structure of the current thresher is simple, the grain threshing is not clean, and there are many sundries, and the sundries are easy to accumulate in the thresher and cause stench, so it is necessary to solve these problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

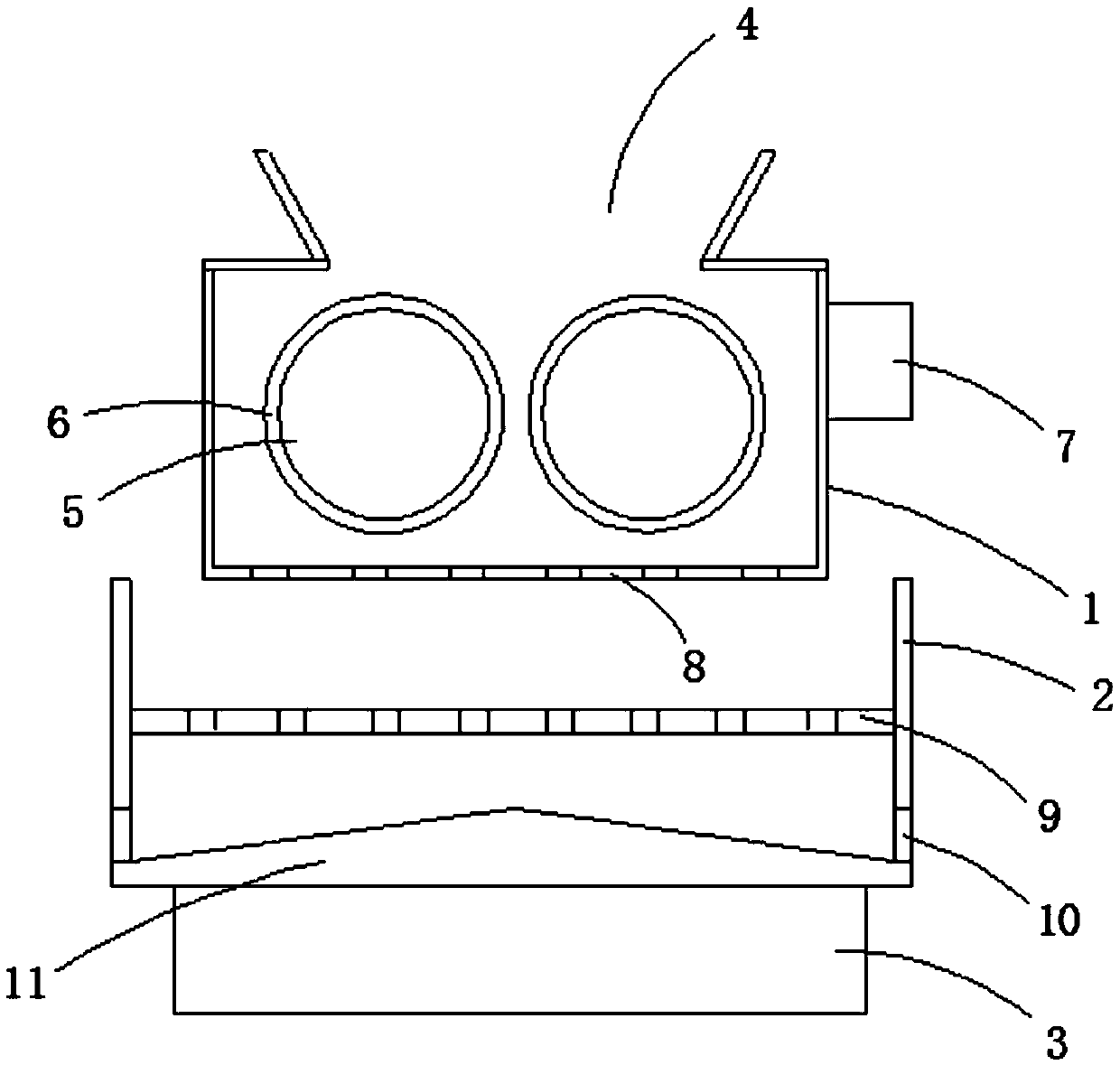

The invention relates to a deodorization grain threshing machine which comprises a threshing cylinder, a grain collecting device and a vibrator, wherein the threshing cylinder is located above the grain collecting device; the vibrator is located on the lower end of the grain collecting device; a grain placement entrance is disposed firmly at the upper end of the threshing cylinder; two rollers are disposed inside the threshing cylinder; the two rollers are disposed in parallel under the grain placement entrance; spiral blades used for threshing are disposed on both the idler wheels; a waste gas purifier based on catalytic-oxidation photodecomposition is disposed on one side of the threshing cylinder; and the bottom part of the threshing cylinder is a screen. In comparison with the prior art, the deodorization grain threshing machine provided by the invention has the advantages of quick threshing, thorough grain threshing and effective removal of stink.

Description

technical field The invention relates to a deodorizing grain thresher. Background technique The current thresher has a simple structure, grain threshing is not clean, and there are many sundries, and it is easy to accumulate sundries in the thresher to generate stench, so it is necessary to solve these problems. Contents of the invention The technical problem to be solved by the present invention is to provide a grain thresher with fast threshing speed, clean grain threshing and effective elimination of stench. The technical scheme of the present invention to solve the above-mentioned technical problems is as follows: a deodorizing grain thresher, comprising a threshing cylinder, a grain collector and a vibrator, the threshing cylinder is placed above the grain collector, and the vibrator placed at the lower end of the grain collector; The upper end of the threshing cylinder is fixedly provided with a grain placement opening, and the inside of the threshing cylinder ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01F7/04A01F12/44A61L9/18

CPCA01F7/04A01F12/446A61L9/18

Inventor 刘刚凌窦均林经本期印海廷毕明华

Owner GUILIN UNIV OF AEROSPACE TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com