Electrical control cabinet

A technology for electrical control cabinets and solenoid valves, applied in electrical components, electrical equipment enclosures/cabinets/drawers, cooling/ventilation/heating renovation, etc. problem, to achieve the effect of obvious air cooling effect, best service life and fast air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

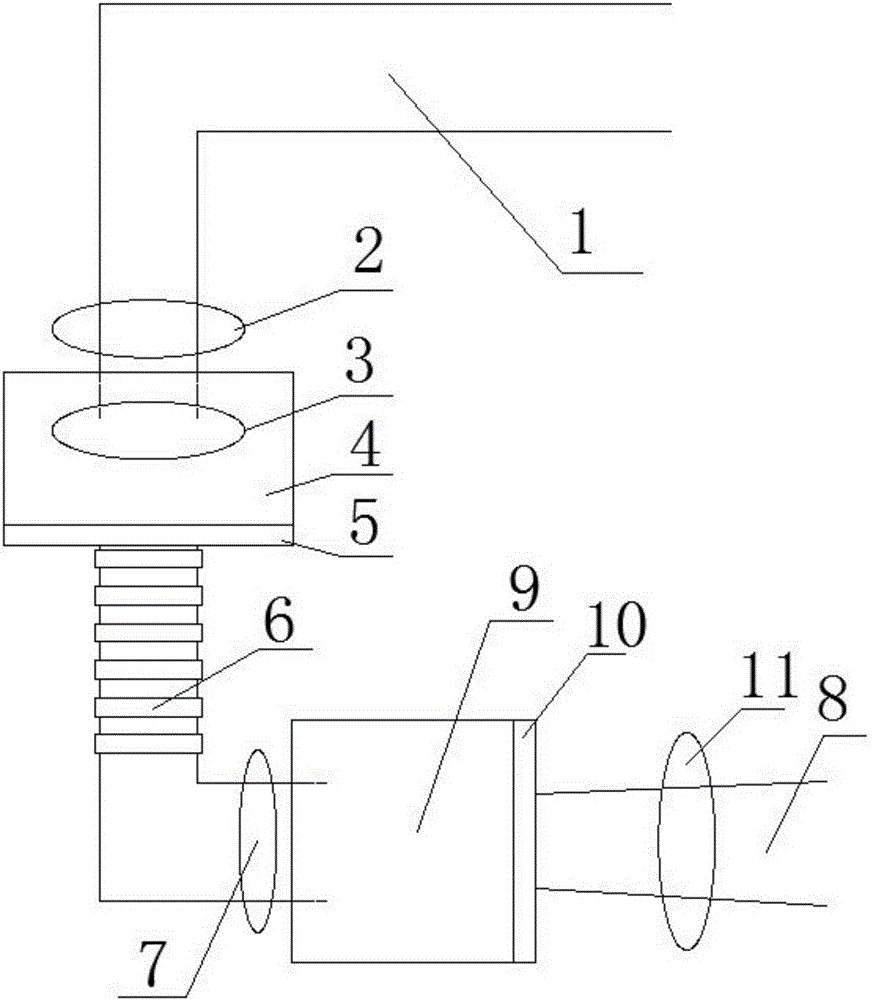

Embodiment 1

[0015] An electrical control cabinet, which cools the inside of the electrical control cabinet through air cooling, and uses manufacturing cold air to cool the components in the electrical control cabinet. Compared with natural cooling, the air cooling effect is more obvious. The characteristics of faster air cooling, and equipped with multiple matching solenoid valves and exhaust systems, can effectively adjust the temperature in the electrical control cabinet, so that the temperature in the electrical control cabinet will not be too high or too low, thus effectively Ensure that the components in the electrical control cabinet can achieve the best service life, such as figure 1 As shown, the following structure is particularly arranged: an exhaust unit that is fixed at the air outlet on the top wall of the electrical control cabinet 4, the exhaust unit includes an air outlet pipe 1, an air outlet pipe solenoid valve 2, and the One end of the air outlet pipe 1 is placed outsid...

Embodiment 2

[0017] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, it can automatically adjust the size of the discharge of hot air outside the cabinet in the electrical control cabinet, thereby avoiding excessively fast or too slow discharge. The waste of energy caused by wind, such as figure 1 As shown, the following structure is particularly provided: an exhaust system 3 is also provided in the electrical control cabinet 4, and the exhaust system 3 is arranged at the top of the electrical control cabinet 4 and is electromagnetically Valve 2 is connected.

Embodiment 3

[0019] This embodiment is further optimized on the basis of the above-mentioned embodiments. In order to better realize the present invention, it can facilitate the connection between the cooling air device and the electrical control cabinet, and can effectively control the air output of the cooling air device, such as figure 1 As shown, the following structure is particularly provided: the cold air pipeline includes a bellows section 6, a round pipe section and an air inlet pipe electromagnetic valve 6 arranged on the round pipe section, one end of the bellows section 6 is connected to the bottom of the electrical control cabinet 4 The air inlet is connected, and the other end of the bellows section 6 is connected with the round pipe section, and the round pipe section is connected with the air outlet of the cold air device 9 through the cold air output solenoid valve solenoid valve 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com