Pulse laser beam combining device and method based on four electrodes

A pulsed laser and four-electrode technology, which is applied to lasers, laser components, circuits, etc., can solve the problems of limited single-channel laser power improvement, high average output power, and affecting laser performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

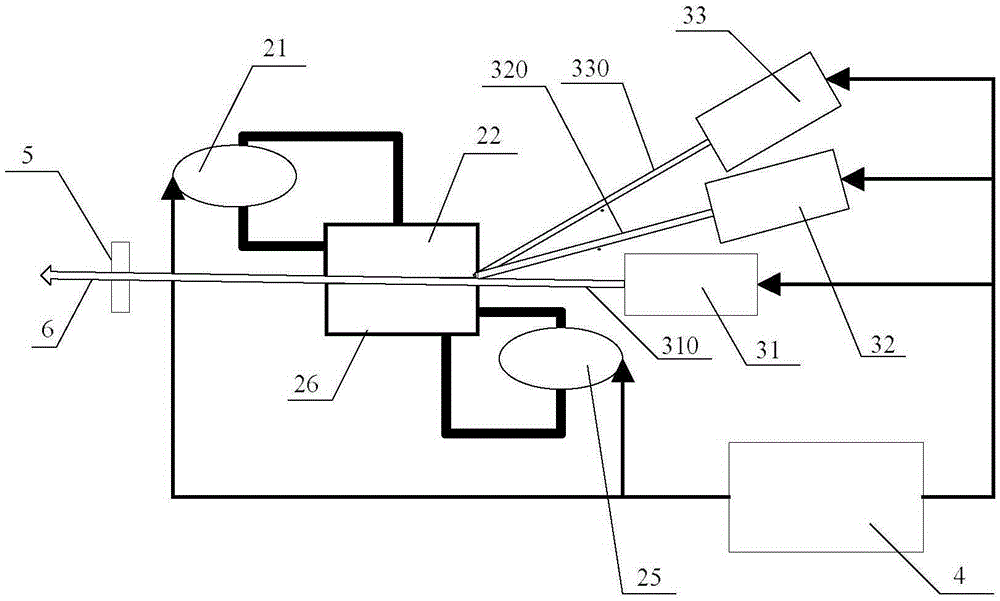

[0033] Such as figure 1 As shown, a pulsed laser beam combiner based on four electrodes includes an electro-optic crystal 1, 2 driving circuits, 3 lasers, a synchronous machine 4 and a laser collimator 5.

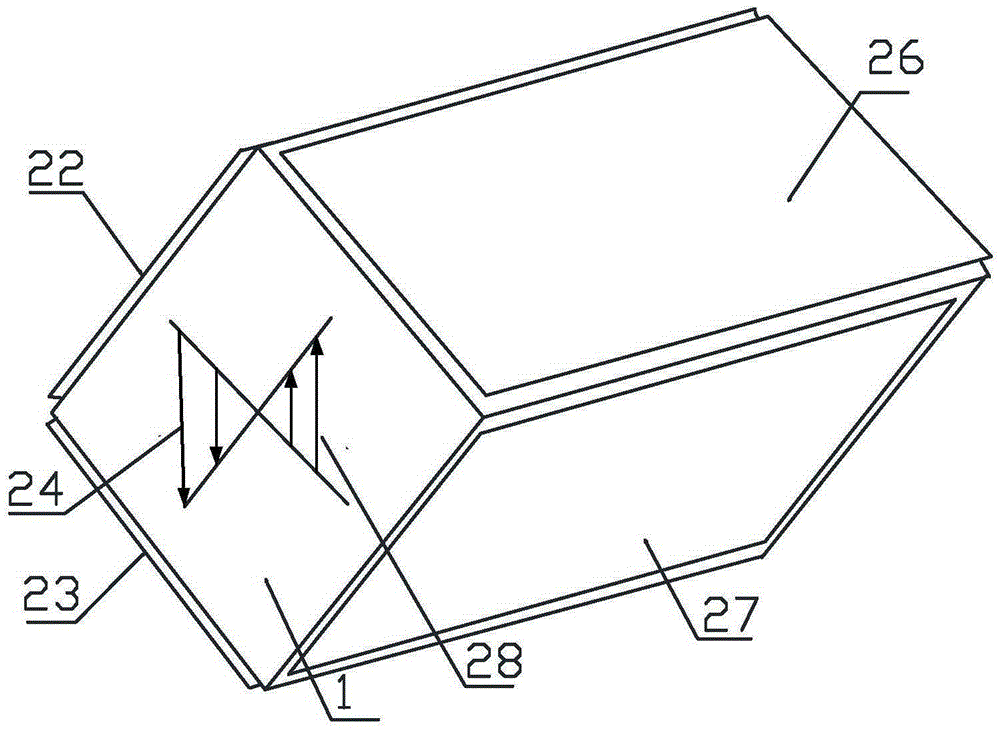

[0034] Such as figure 2 As shown, the electro-optic crystal 1 is a quadrangular prism with 4 sides and 2 bottoms; the electrode plate 22 and the electrode plate 23 of the driving circuit 21 are respectively in contact with two adjacent sides of the electro-optic crystal 1, and the driving circuit The electrode plate 26 and the electrode plate 27 of 25 are in contact with the other two sides of the electro-optic crystal 1 respectively, the electrode plate 22 is connected to the positive pole of the drive circuit 21, the electrode plate 23 is connected to the negative pole of the drive circuit 21, and the electrode plate 26 is connected to the drive circuit 25. Negative pole, electrode plate 27 connects the positive pole of drive circuit 25; Like this forms an electric fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com