Gas chromatography detection system and method for online analysis of trace He, H2 and impurity components in Ne

A detection system and gas chromatography technology, which can be used in analysis materials, measurement devices, material separation, etc., and can solve the problems of measurement influence, difficulty in accurate quantification, and small memory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

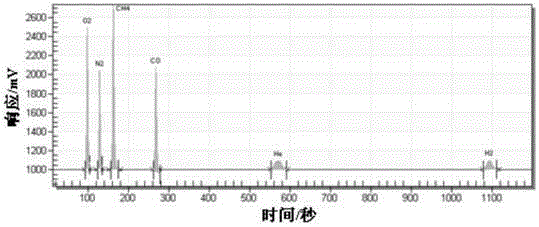

[0075] Example 1: O in Ne 2 , N 2 、CH 4 , CO, H 2 , Detection and analysis of He components

[0076] Detection of O in Ne 2 , N 2 、CH 4 , CO components (both 50ppm) and He, H 2 When the components (both are 100ppm), the entire gas path is purged first, the sample gas flow rate is 25mL / min, and the sampling pressure is 10psi. After the output is stable, the detection and analysis of each component can be started. It mainly includes the following three steps:

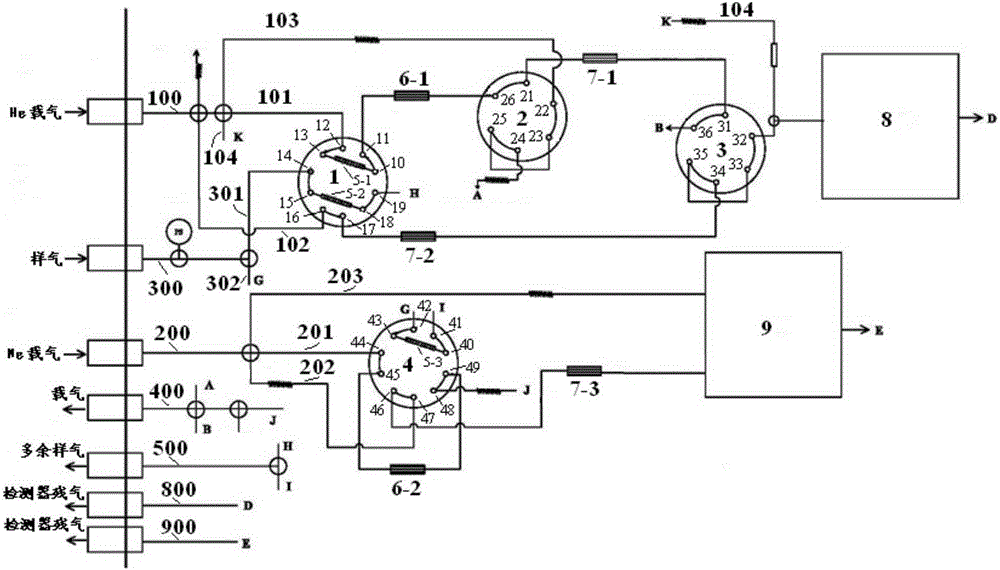

[0077] ① Analysis of O in Ne 2 , N 2 、CH 4 , CO component: the sample gas is quantified through the quantitative tube Ⅱ5-2, and the excess gas is emptied through the sample gas outlet, that is, the ninth port 19 of the ten-way valve Ⅰ1. The specific gas circuit sequence is as follows figure 1 Shown; Secondly, the sample gas in the He carrier gas carrying band quantitative tube II 5-2 of He carrier gas second introduction branch 102 imports enters the second separation chromatographic column 7-2 (molecular sieve...

Embodiment 2

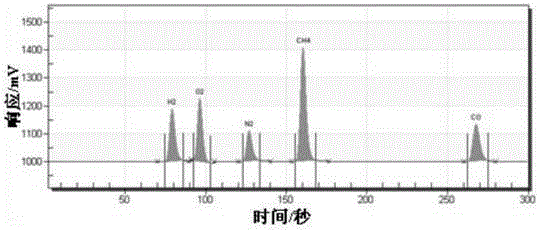

[0081] Example 2: H in He 2 , O 2 , N 2 、CH 4 , Detection and analysis of CO components

[0082] Detection of H in He 2 (50ppm), O 2 , N 2 、CH 4 , CO (both 5ppm) components, the entire gas path is purged first, the sample gas flow rate is 25mL / min, and the sampling pressure is 10psi. After the output is stable, the detection can be started. The detection process is the same as in Example 1. Middle Ne Middle O 2 , N 2 、CH 4 The detection process of , CO components is the same, and finally tested by PED8.

[0083] Figure 9 H in He 2 (50ppm) and O 2 , N 2 、CH 4 , CO (both 5ppm) and the chromatograms of the impurity components, it can be seen that the separation of each component is very obvious, and the separation can be completed within 300s. 2 The detection limit of the components is less than 26ppb, and the detection limits of other components are all less than 3ppb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com