Sheet metal micro-crack time reversal positioning method based on abaqus

A technology of time reversal and positioning method, which is applied in the direction of processing detection response signals, etc., can solve the problems of ignoring dispersion characteristics and inaccurate calculation results, and achieve the effect of convenient operation, time saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

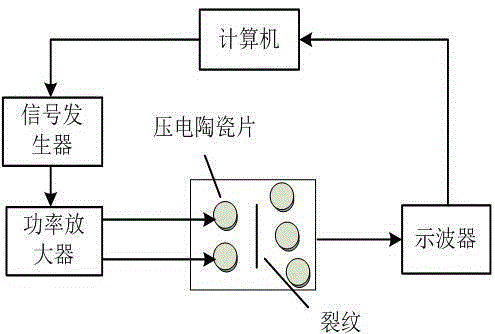

[0022] Dynamic sound modulation detection system such as figure 1 As shown, it mainly includes: a thin aluminum plate with a length of 400mm, a width of 200mm, and a thickness of 2mm, with a Young’s modulus of 72GPa and a Poisson’s ratio of 0.35. There is a closed crack at the center of the plate with a length of 10mm and a width of nano-micro; the diameter is 25mm, Thickness stretchable piezoelectric ceramic sheet with a thickness of 2mm and a center frequency of 40kHz; signal generator (DG1022U); oscilloscope (DS2102); power amplifier (JYH-200M), etc.

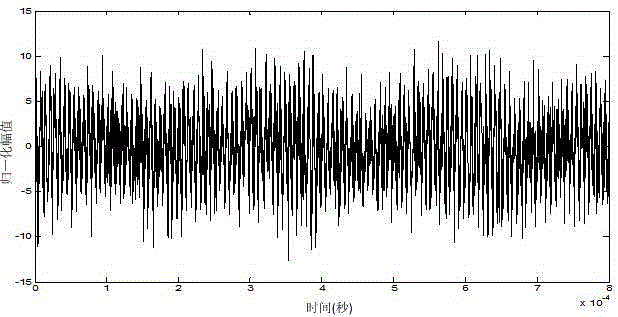

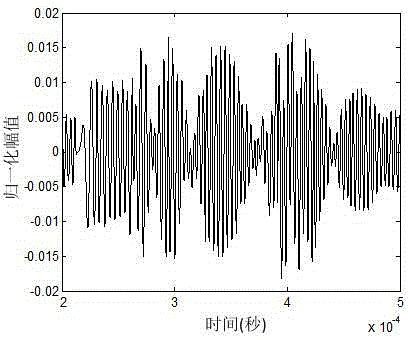

[0023] Because when the frequency of the vibration signal is selected as the modal frequency of the specimen, the phenomenon of vibration-acoustic modulation is most obvious. Therefore, first perform a modal test on the specimen, select the frequency sweep mode in the signal generator, set the start frequency to 1000Hz, the end frequency to 6000Hz, the amplitude to 100V, and the sampling frequency to 1MHz. The signal is inpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com