Tension force applying device for steel wire with small diameter

A technology of applying device and steel wire, which is applied in the direction of measuring device, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of cumbersome operation and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

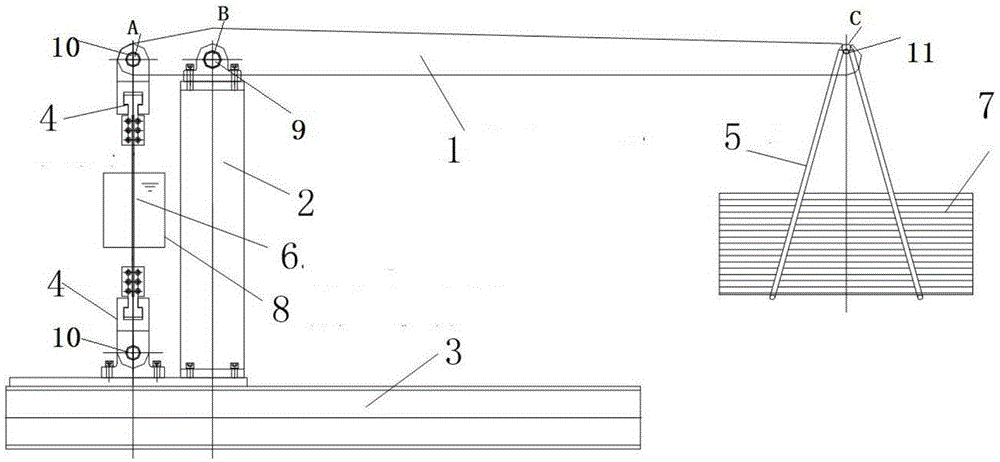

[0020] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

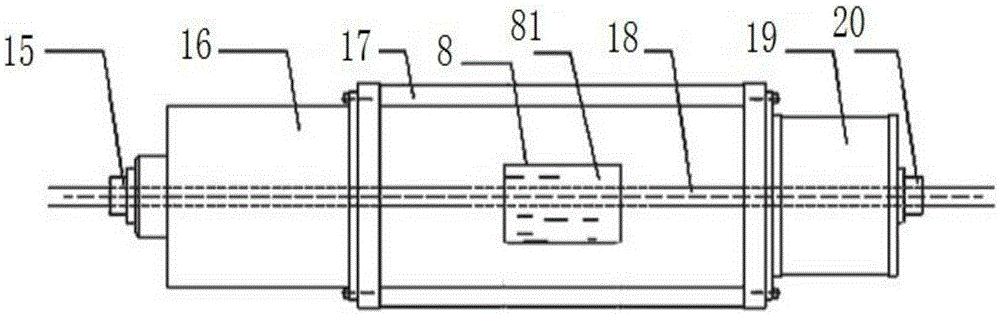

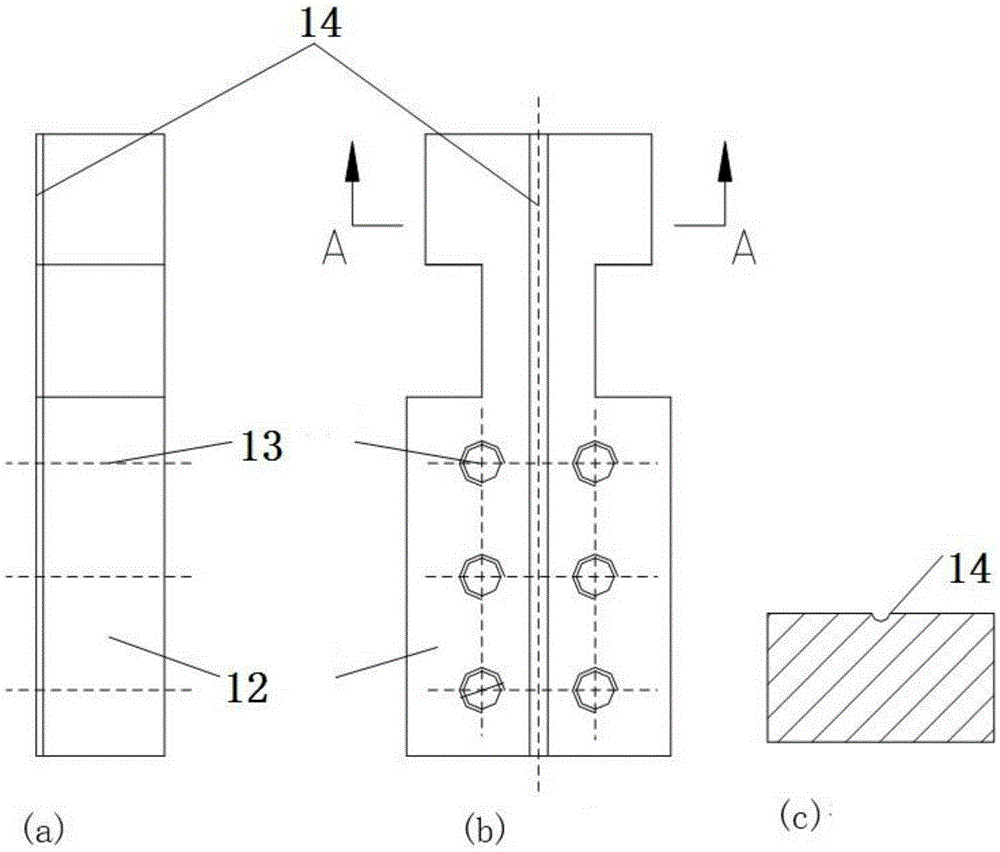

[0021] Such as figure 2 As shown, the present invention discloses a small-diameter steel wire tensioning force application device based on the principle of leverage. The device as a whole is a self-balancing lever, including a base 3, a column 2, a lever 1, a standard counterweight 7, a pair of clamps 4, Corrosive solution container 8, the pair of clamps 4 are composed of upper clamps and lower clamps;

[0022] The bottom end of the column 2 is fixed on the base 3;

[0023] Described lever 1 is in the direction of its arm length, at point B, moves by rotating shaft frame 9 and is limited to the top of column 2, and at point C, a standard counterweight 7 is suspended by counterweight frame 5, and at point A The upper clamp is hinged by the rotating shaft 10, and the horizontal length between BC is greater than the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com