Pulse laser seed source light detection tool

A technology of pulsed laser and detection tooling, applied in measurement devices, photometry, optical radiation measurement, etc., can solve problems such as stability and poor consistency, and achieve the effects of high consistency, fast connection, and stable testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

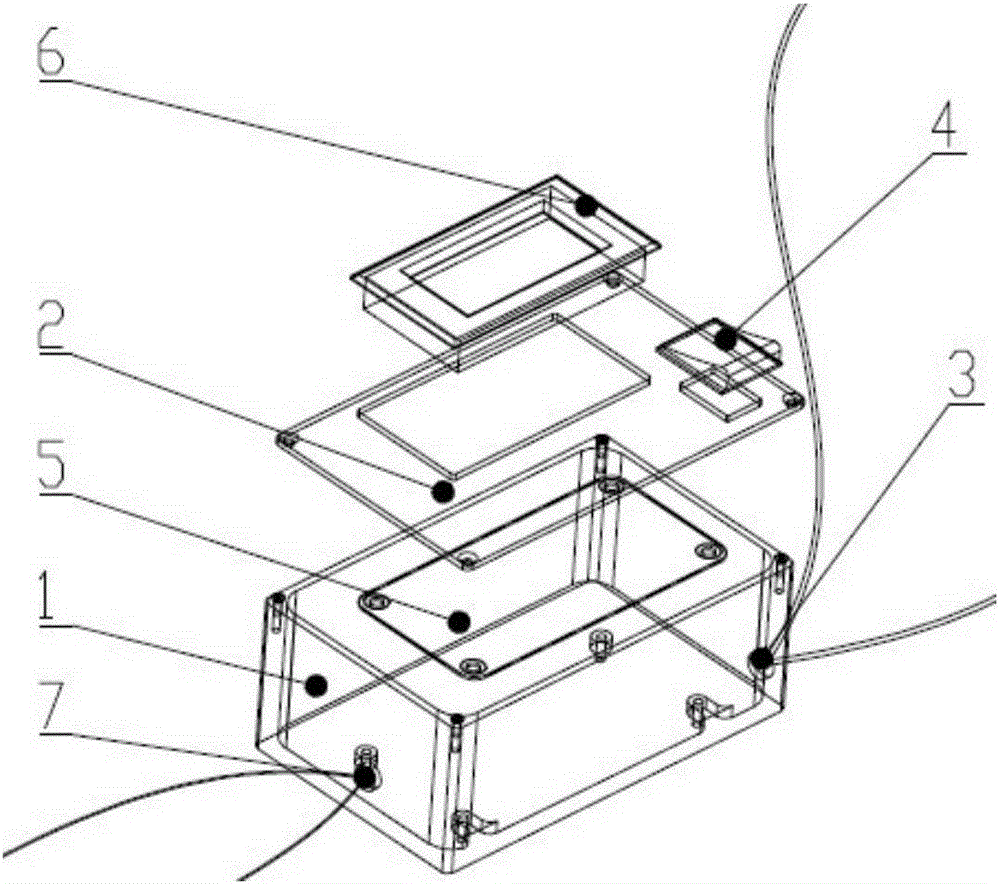

[0047] Such as image 3 with Figure 4 Shown is an exploded view and a schematic diagram of the external structure of an embodiment of the pulse laser seed source light detection tooling provided by the present invention, by image 3 It can be seen that in the embodiment of the pulse laser seed source light detection tool provided by the present invention: base 1, cover plate 2, power cord 3, power switch 4, circuit board 5, digital display screen 6 and test lead 7.

[0048] The base 1 is in the shape of a hollow cuboid with an opening on the bottom surface, and the circuit board 5 is arranged inside the base 1 . The cover plate 2 has a plate shape corresponding to the size of the opening, and the power switch 4 and the digital display screen 6 are arranged on the cover plate 2 . Two through holes are arranged on the side of the base 1, and the power line 3 and the test lead 7 are respectively connected to the external mains power supply and the light monitoring point of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com