Liquid ring conveying system and method for high-thickness materials

A conveying system and high-viscosity technology, used in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of high cost, large conveying energy consumption, large friction resistance, etc., to reduce flow resistance, reduce Small pipe transmission energy consumption, drag reduction effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

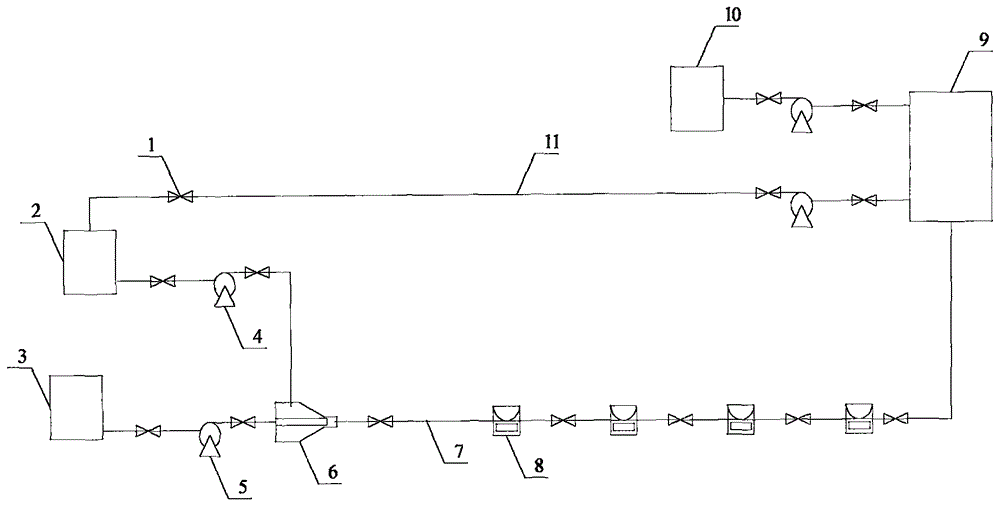

[0026] Such as figure 1 As shown, the highly viscous material liquid ring delivery system provided by the present invention includes a valve 1, a low-viscosity storage tank 2, a starting point storage tank 3, a low-viscosity infusion pump 4, a high-viscosity material infusion pump 5, and a cartridge mixer 6. Liquid ring delivery pipeline 7 , liquid ring maintenance device 8 , separator 9 , terminal storage tank 10 , infusion pipeline 11 .

[0027] The low-viscosity storage tank 2 is used to store the low-viscosity liquid which is substantially insoluble with the high-viscosity liquid and is used to form a liquid ring. The starting point storage tank 3 stores high-viscosity substances, and the low-viscosity and high-viscosity substances are respectively It is delivered to the cartridge mixer 6 through the low-viscosity infusion pump 4 and the high-vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com