Double-U-shaped clamp-type anti-skidding universal wall-connecting part for scaffold

A technology for connecting wall parts and scaffolding, which is applied to the field of double U-shaped clamp type anti-skid universal wall connecting parts of scaffolding, can solve the problems of difficult recycling, insufficient sliding resistance and strength, bulging and leakage hidden dangers, etc. Convenience, saving labor and materials, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

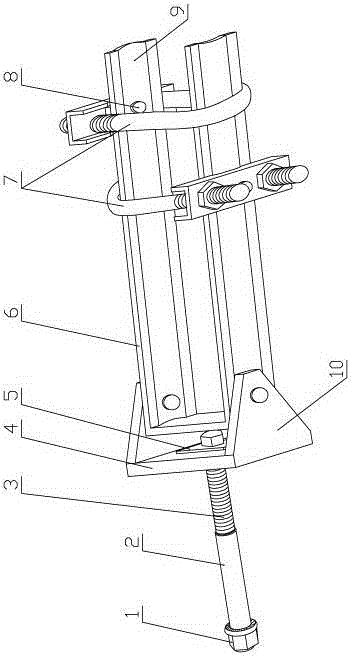

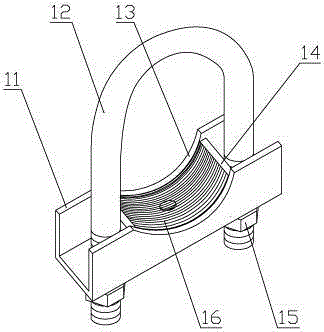

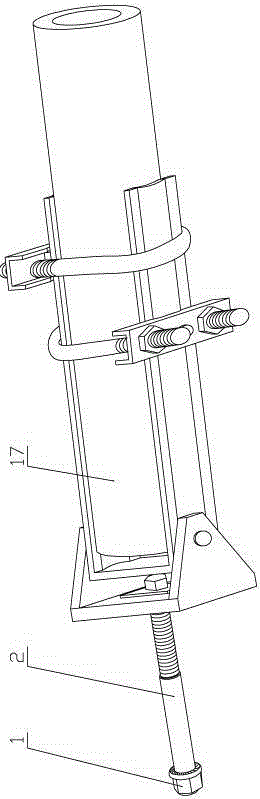

[0015] see figure 1 , figure 2 , the present invention is a double U-shaped clamp type non-slip universal wall connecting piece for scaffolding, which has a wall connecting piece body. Clamp anti-slip assembly, wherein the tension screw is connected to the base of the wall, the other end of the tension screw is set with a cover nut 1 with a PVC sleeve 2, and the two sides of the rear part of the U-shaped splint are respectively connected to the two sides of the base of the wall. Side hinged, the double U-shaped clamp anti-skid assembly is set in the opening of the front end of the U-shaped splint and connected with the support plates on both sides of the U-shaped splint through pin shafts 8 .

[0016] In this embodiment, the wall base has a bottom plate 4, and hinge ears 10 are arranged symmetrically on both sides of the bottom plate, and the two hinge ears are hinged to both sides of the U-shaped splint.

[0017] In this embodiment, the inner side walls of the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com