Multi-multiplying-power lifting mechanism of mechanical decontamination slusher

A technology of cleaning rake bucket and lifting mechanism, which is applied in the direction of open water surface cleaning, water conservancy engineering, construction, etc., can solve the problems of increasing the overall investment in cleaning equipment, increasing investment in cleaning equipment, and complex structure of the opening and closing mechanism, etc. To achieve the effect of compactness, wide practicability and overall size reduction of cleaning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

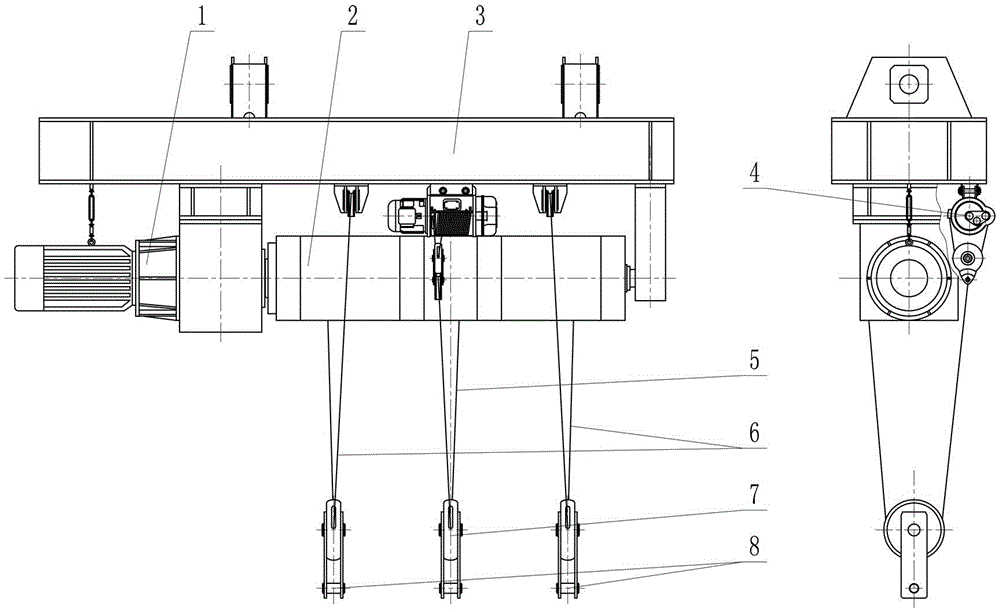

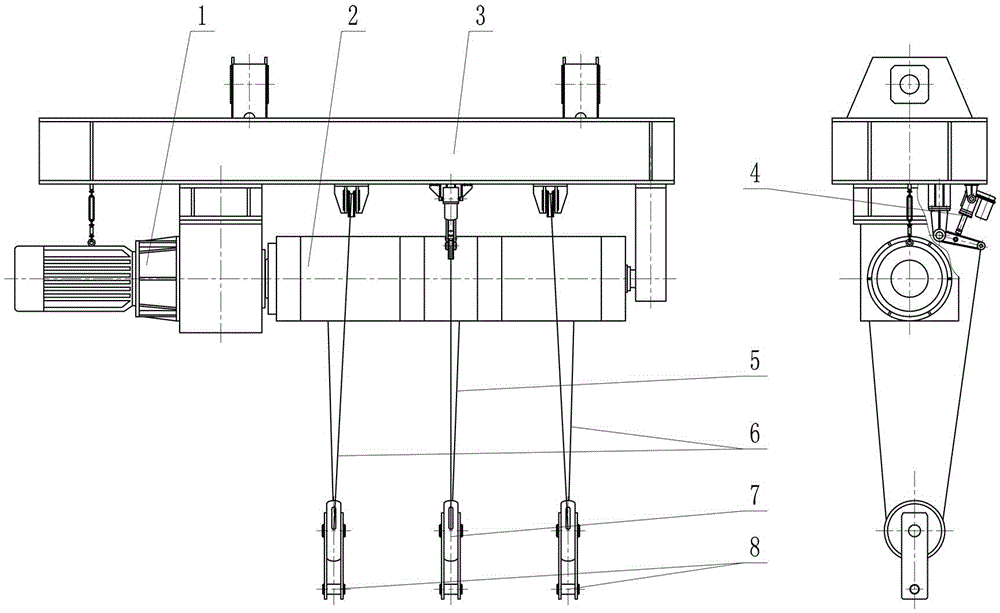

[0011] figure 1 It is a structural schematic diagram of Embodiment 1 of the multi-rate lifting mechanism of the mechanical cleaning rake bucket of the present invention. figure 1 The multi-rate hoisting mechanism of the mechanical cleaning rake bucket shown in includes a hoisting wire rope 6, a bucket-opening wire rope 5, a multi-rate hoisting device 8 for the hoisting wire rope, and a multi-ratio hoisting device 7 for the bucket-opening wire rope. The reel device 2 of the lifting wire rope and the bucket opening wire rope, the driving mechanism 1 of the reel device, and the frame 3 of the hoisting mechanism are different from the prior art in that the end of the bucket opening wire rope 5 is also provided with a rake bucket to generate Open and close wire rope retractable device 4. figure 1 The wire rope retracting device 4 in Embodiment 1 of the present invention is an electric hoist, and the opening and closing of the rake bucket can be controlled by retracting and releasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com