Washing machine and method for backwashing its pre-filter

A pre-filter and reverse flushing technology, which is applied in the field of washing machines, can solve problems such as pollution, filter membrane clogging, and filter effect effects, and achieve the effects of reducing costs, prolonging life, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

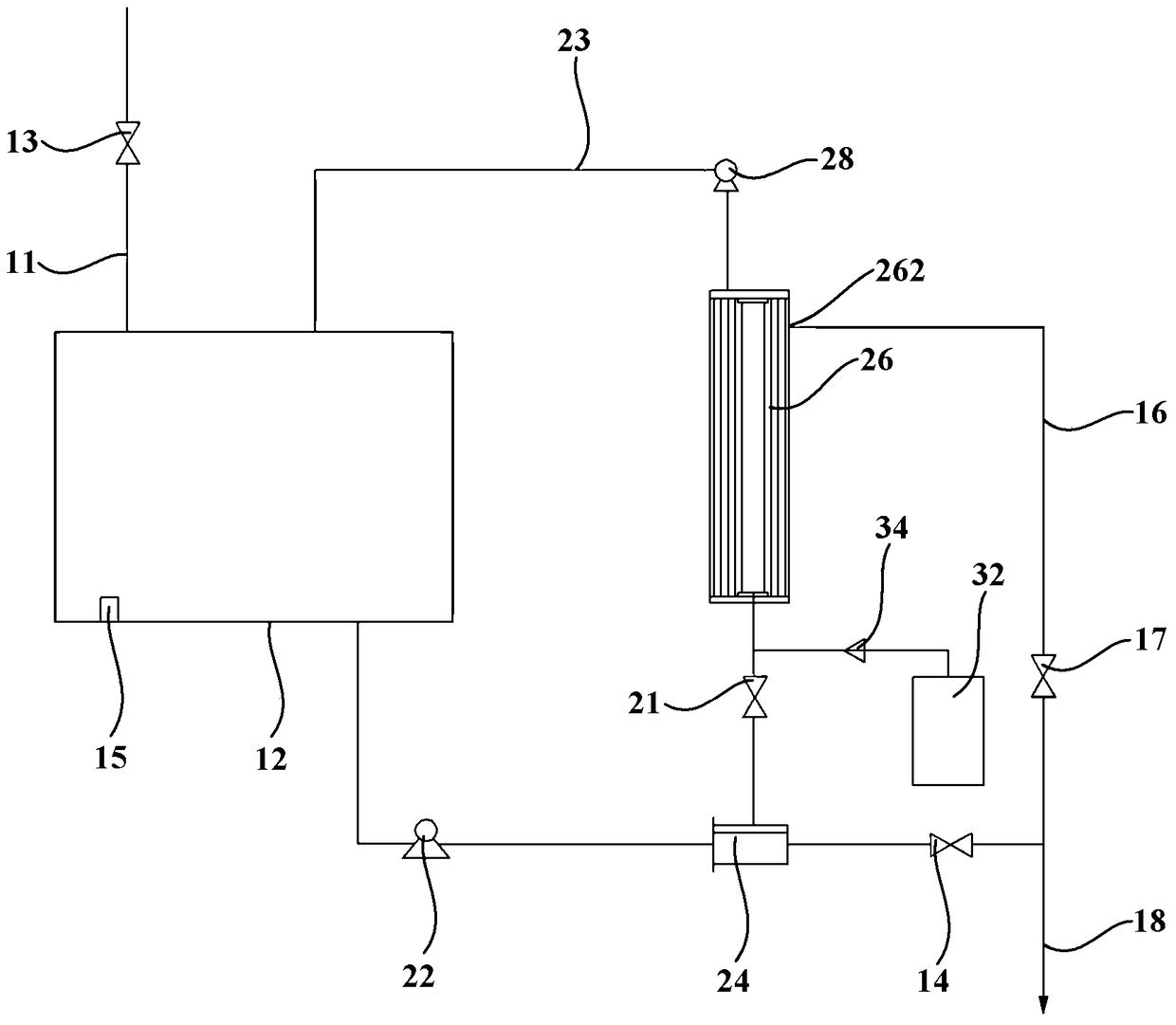

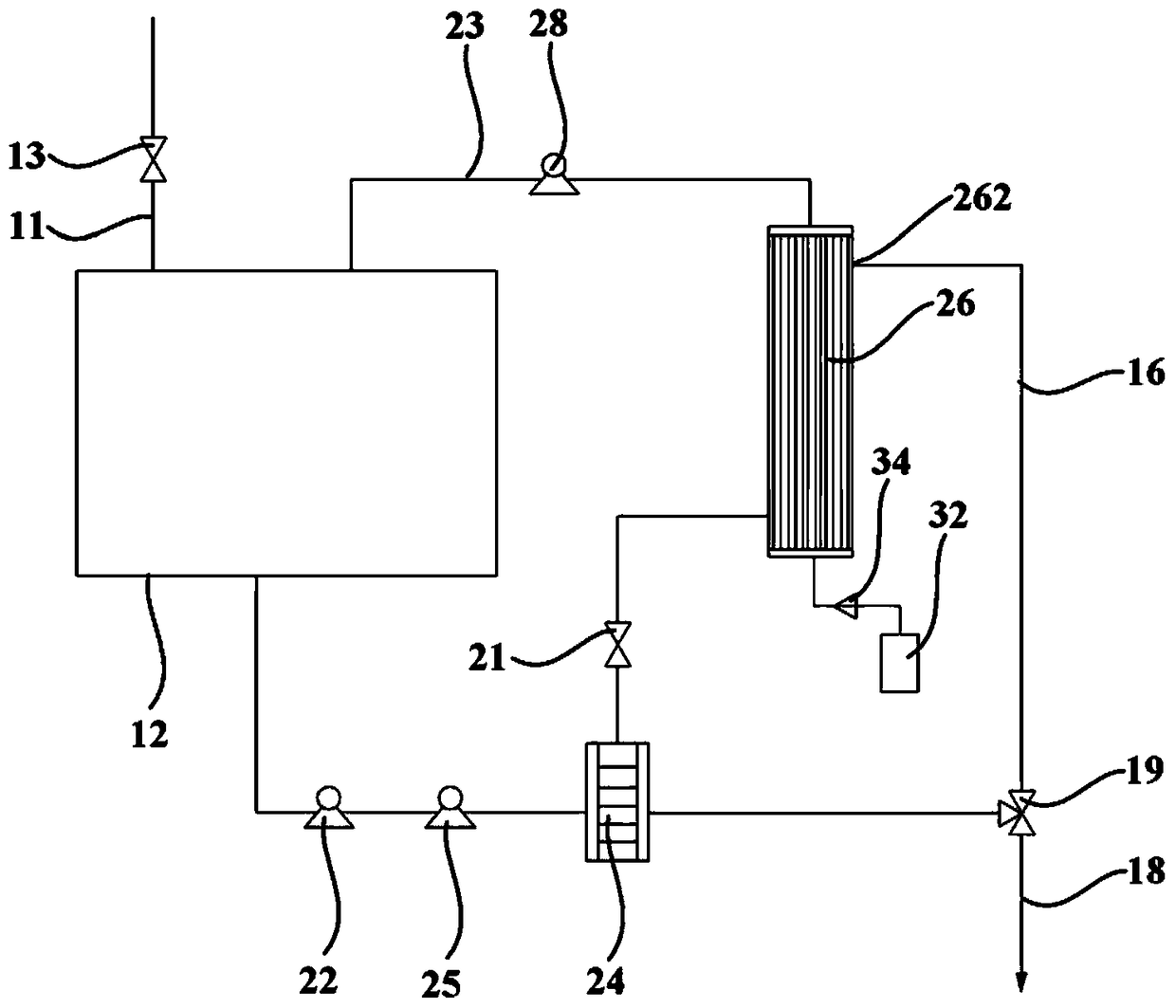

[0041] figure 1 is a schematic schematic diagram of a washing machine according to an embodiment of the present invention. The washing machine in this embodiment may include a casing (not shown in the figure), a washing tub 12 disposed in the casing, and a circulating water filtering system. The circulating water filtration system of the present invention may include a pre-filter 24 and a filter membrane module 26 arranged on the pipeline downstream of the pre-filter 24 . The pre-filter 24 and the filter membrane assembly 26 can be configured to filter the water discharged from the washing tub 12 during the circulating water filtration process, so as to circulate back to the washing tub 12 for reuse. Wherein the pre-filter 24 is used as an upstream filter to first filter the water from the washing cylinder 12, and the filter membrane assembly 26 is used as a downstream filter to filter the water filtered by the pre-filter 24 again (those skilled in the art can understand that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com