ECMA (ecols composite microbial agents) preparation method

A composite microbial inoculum and a manufacturing method technology, applied in the field of bioengineering, can solve problems such as the surge in production costs, the destruction of micro-ecological balance, and the aggravation of soil-borne diseases, so as to reduce the occurrence of soil-borne diseases, inhibit growth and reproduction, and promote effect on growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The first step is to cultivate the slant. Inoculate the strain Penicillium on the sterilized slant medium, and then put these test tubes into the incubator and cultivate them on the slant at 28°C for one week until the aerial spore piles turn green.

[0047] In the second step, shake flask strain culture.

[0048] The medium formula used: glucose 30g / l, KH 2 PO 4 6g / l, K 2 HPO 4 2.3g / l, (NH 4 ) 2 SO 4 3g / l, MgSO 4 ·7H 2 O0.2g / l, corn steep liquor 2g / l, adjust pH to 7.5.

[0049] In a 500ml Erlenmeyer flask equipped with a shaker flask strain culture medium, the filling volume is 100ml, inoculate the above-mentioned slant culture strain, and cultivate it for 26 hours at 150 rpm on a shaker at 30°C.

[0050] The third step is seed cultivation in liquid fermenter.

[0051] The medium formula used: glucose 120g / l, KH 2 PO 4 2g / l, K 2 HPO 4 2.5g / l, (NH 4 ) 2 SO 4 5g / l, MgSO 4 ·7H 2 00.2g / l, amino acid granule 8g / l, pH value is 7.5, prepares 350 liters of ...

Embodiment 2

[0060] The first step is to cultivate the slant. Inoculate the strain Penicillium on the sterilized slant medium, and then put these test tubes into the incubator and cultivate them on the slant at 30°C for one week until the aerial spore piles turn green.

[0061] In the second step, shake flask strain culture.

[0062] The medium formula used: glucose 35g / l, KH 2 PO 4 1g / l, K 2 HPO 4 1.33g / l, (NH 4 ) 2 SO 4 4g / l, MgSO 4 ·7H 2 O0.2g / l, corn steep liquor 2.5g / l, adjust pH to 7.2.

[0063] In a 500ml Erlenmeyer flask equipped with a shaker flask strain culture medium, the filling volume is 100ml, inoculate the above-mentioned slant culture strain, and cultivate for 26 hours at 150 rpm on a shaker at 32°C.

[0064] The third step is seed cultivation in liquid fermenter.

[0065] The medium formula used: glucose 100g / l, KH 2 PO 4 1.5g / l, K 2 HPO 4 2g / l, (NH 4 ) 2 SO 4 6g / l, MgSO 4 ·7H 2 00.2g / l, amino acid granule 10g / l, pH value is 8.0, prepares 350 liters of...

Embodiment 3

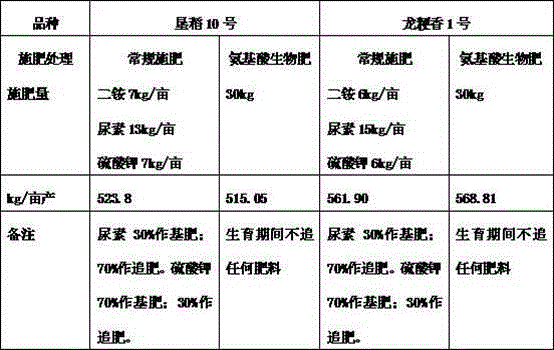

[0074] 1 ton of amino acid granules was mixed with 20 kg of ECMA to make amino acid bio-fertilizer, and the organic rice planting test was carried out. The comparative test of amino acid bio-fertilizer and inorganic fertilizer is shown in the table below. The planting results showed that applying 30kg of amino acid bio-fertilizer per mu at one time, without applying any fertilizer during the growth period, can still ensure strong plants, well-developed root system, dark green color, and no defertilization, and the yield level is basically the same as that of conventional fertilization.

[0075] Effect of Amino Acid Biofertilizer on Organic Rice Yield (2014)

[0076] Organic food rice yield measurement unit: kg / ㎡

[0077] deal with

average Yield per mu bio organic fertilizer 0.85 0.89 0.9 0.87 582.5 "733" organic fertilizer 0.82 0.80 0.83 0.817 544.7

[0078] Explanation: The actual yield is measured in the field, 3 point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com