Good wear resistance and alcohol resistance acrylic resin for aqueous plastic cement

An acrylic resin and wear-resistant technology, which is applied in the field of acrylic resin for water-based plastics. It can solve the problems of water resistance, alcohol resistance, poor adhesion, poor product leveling, and inability to achieve solvent-based paints, etc., and achieve strong hydrophobicity. , Excellent slipperiness and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

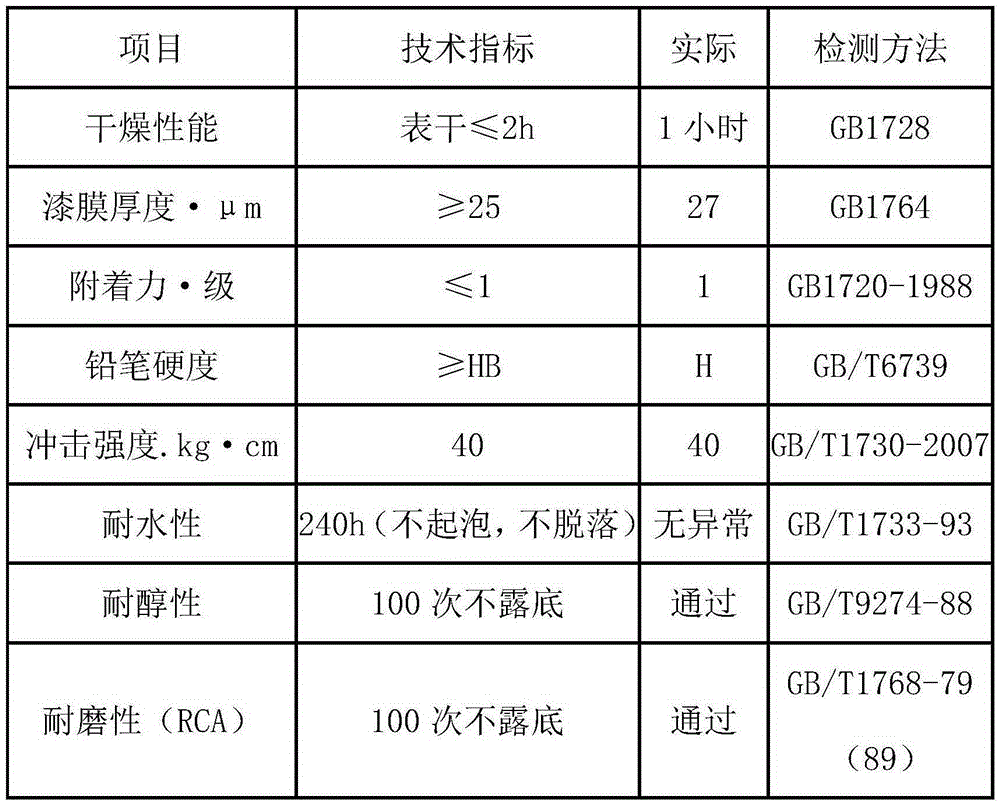

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific examples, and the implementation scope of the present invention is not limited thereto.

[0020] The acrylic resin for water-based plastics with good abrasion resistance and alcohol resistance in this embodiment is prepared according to the following method.

[0021] Step a, put 30-40 parts of solvent into the reaction kettle, and raise the temperature to 140-150°C.

[0022] Step b. Slowly add the following raw materials into the reactor in sequence according to the mass fraction: 30-50 parts of methyl methacrylate, 2-5 parts of trimethylolpropane triacrylate, 5-10 parts of styrene, 5 parts of unsaturated carboxylic acid -10 parts, 1-3 parts of epoxy organosiloxane monomer, 1-2.5 parts of initiator, the feeding time is 2-4 hours, and the reaction temperature is 140-150°C.

[0023] Step c, heat preservation in the reactor for 2 to 3 hours.

[0024] Step d. Add 0.1-0.5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com