Steel pipe straightening device

A technology for straightening and steel pipes, applied in the field of steel pipe straightening devices, can solve the problems of insufficient cooling time, failure to achieve expected results, and bending of steel pipes, and achieve the effects of convenient operation, obvious straightening effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

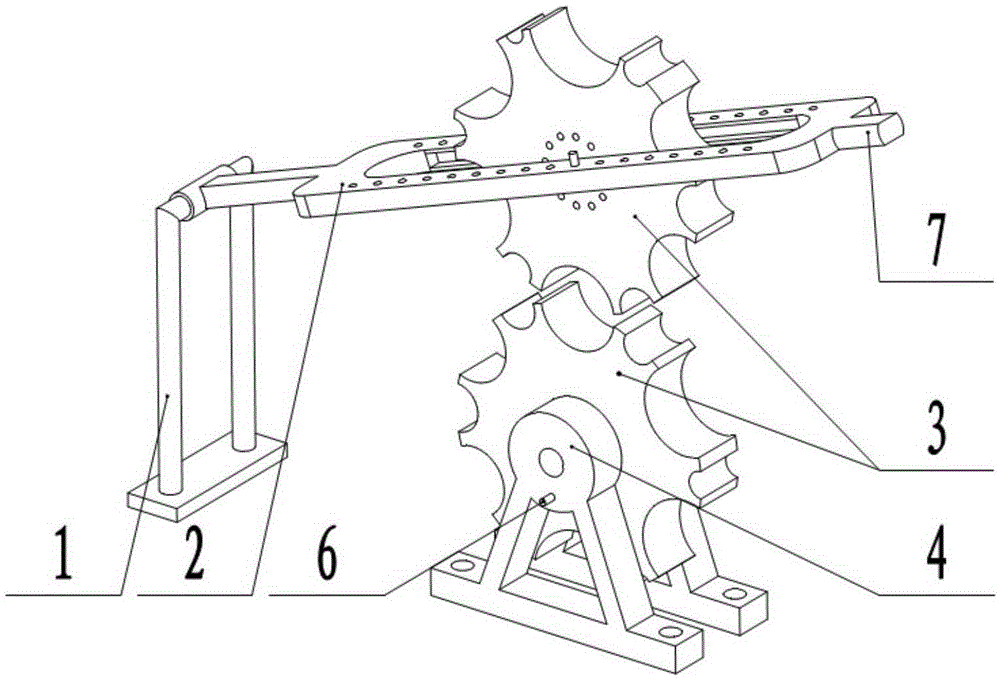

[0015] Such as figure 1 As shown, a steel pipe straightening device includes a frame 1, a straightening plate 2, a straightening mold 3, a base 4 and a handle 7.

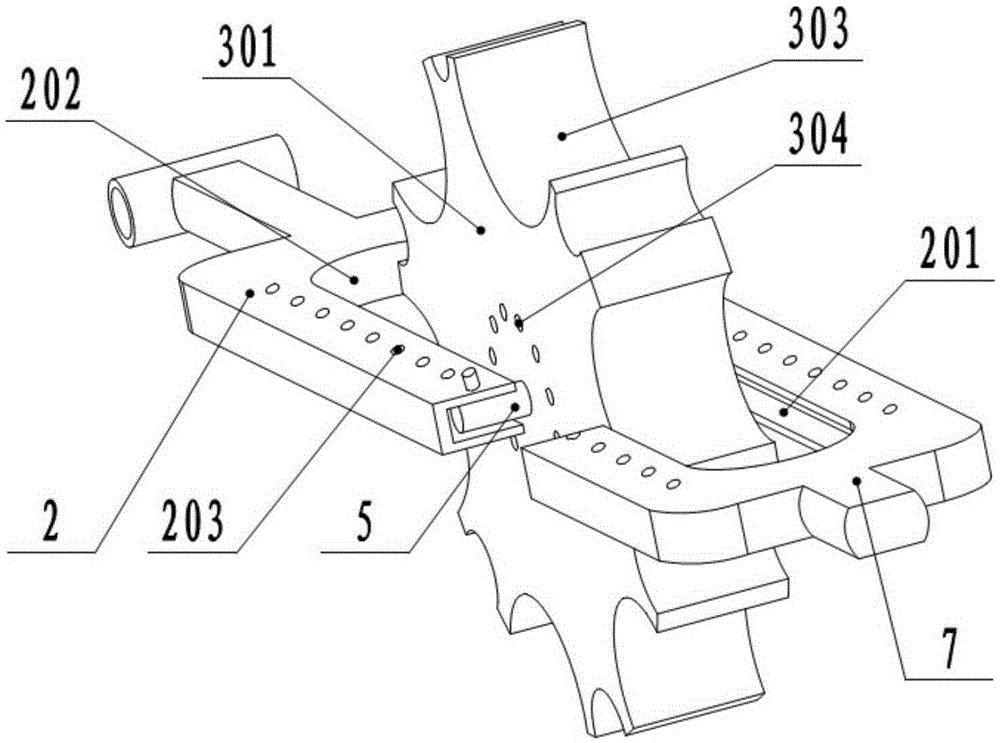

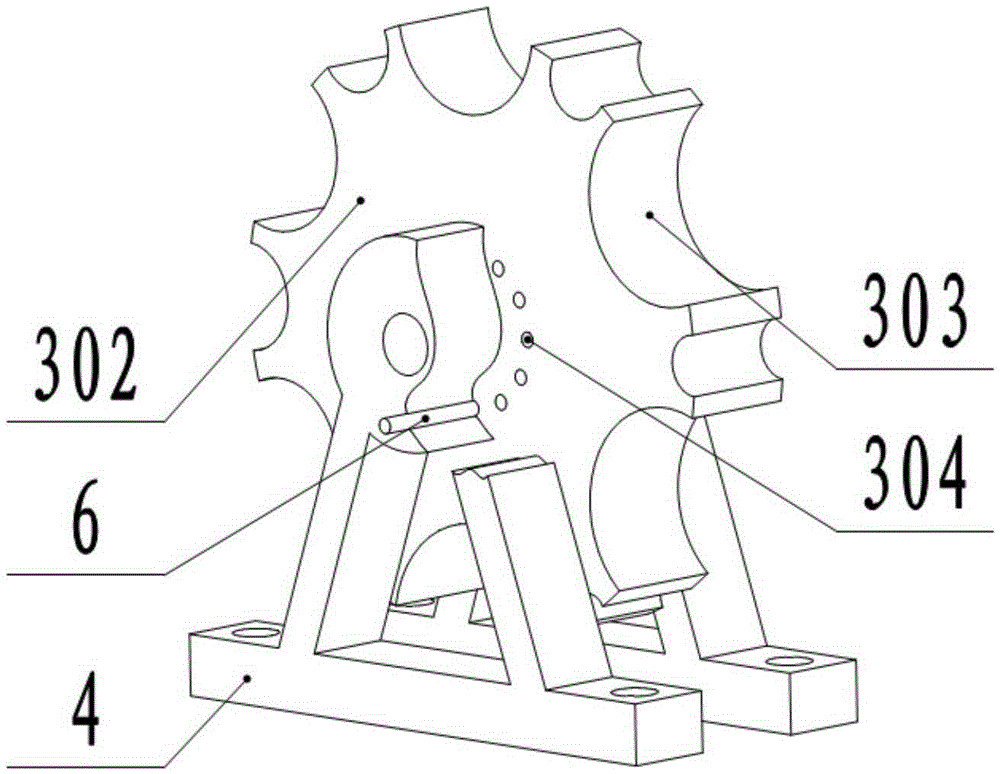

[0016] One end of the straightening plate 2 is hinged to the frame 1. The straightening plate 2 is provided with a slot 202 and a plurality of adjustment holes 203. The slot 202 is located at the center of the straightening plate 2. The plurality of adjustment holes 203 are distributed symmetrically on both sides of the slot 202. Straightening mold 3 comprises upper mold wheel 301 and lower mold wheel 302, upper mold wheel 301 and lower mold wheel 302 are symmetrically arranged up and down, upper mold wheel 301 passes slotted hole 202, is connected with straightening plate 2, lower mold wheel 302 and The base 4 is rotatably connected; the handle 7 is located at the end away from the frame 1 and is fixedly connected with the straightening plate 2 .

[0017] Both the upper mold wheel 301 and the lower mold wheel 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com