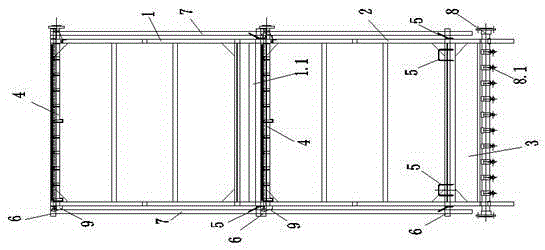

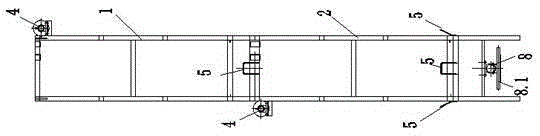

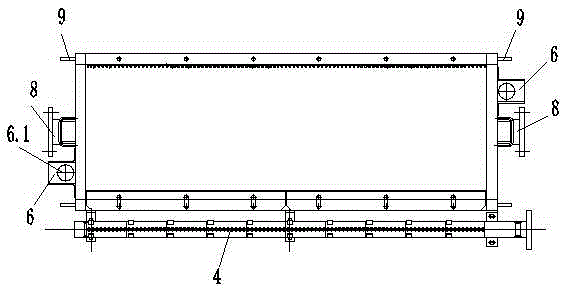

Double-layer flat membrane module

A double-layer flat plate, membrane module technology, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve the problems of poor anti-pollution ability, high installation and construction difficulty, frequent cleaning, etc. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: a double-layer flat membrane module, including upper and lower two-layer support (1, 2) and the aeration membrane box 3 of the bottom, the upper and lower two-layer support (1, 2) is provided with a flat membrane module, the upper support 1 The bottom end is provided with a water collection pipe reserved outlet 1.1, the top side of the upper support 1 is provided with a water collection pipe 4, the top side of the lower support 2 is provided with a water collection pipe 4, and the top of the lower support 2 is provided with an inclined guide U-shaped along the surrounding edges of the support. Frame 5, the bottom end of the upper frame 1 guides the insertion frame to the top of the lower frame 2 through the guiding U-shaped frame 5, and the top of the aeration membrane box 3 is also provided with an inclined guiding U-shaped frame 5 along the surrounding edges, and the bottom end of the lower frame 2 Through the guide U-shaped frame 5, the guide frame is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com