Mobile phone test assembly line

A mobile phone testing and assembly line technology, applied in the field of assembly line, can solve the problems of incomplete types of test functions, low qualified rate of mobile phone finished products, increased inspection workload, etc., and achieve the effects of improving the qualified rate of inspection, fast inspection speed and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

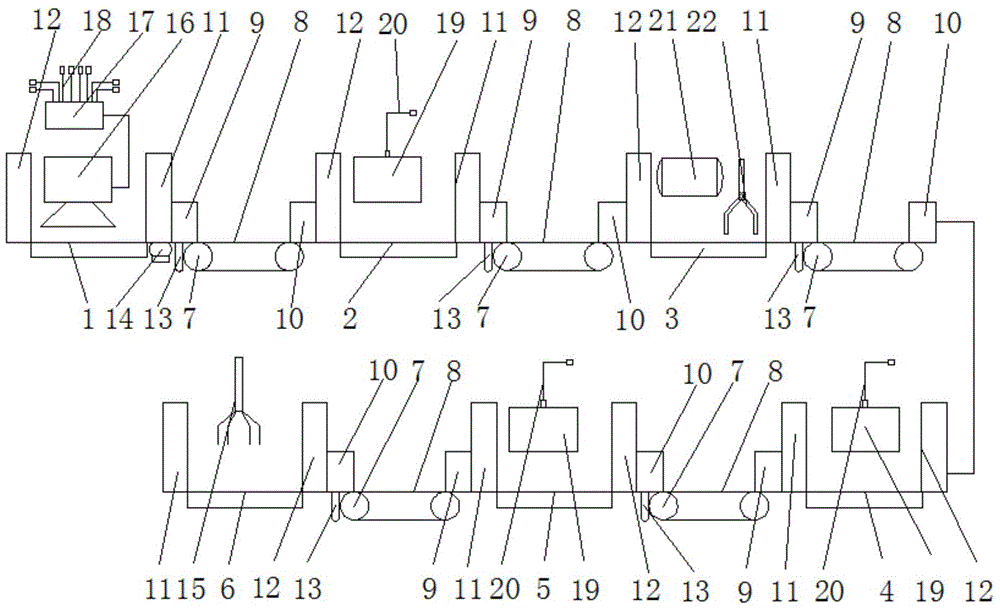

[0021] like figure 1 As shown, the present embodiment includes download test device 1, calibration device 2, man-machine interface test device 3, echo test device 4, network test device 5 and finished product packaging device 6, download test device 1, calibration device 2, man-machine interface Between the test device 3, the echo test device 4, the network test device 5 and the finished product packaging device 6, a belt conveyor 7 is arranged in sequence, and a conveyor belt 8 is arranged on the belt conveyor 7, and a material receiving port 9 and a conveyor belt 8 are arranged at both ends of the conveyor belt 8. The feed port 10, the feed port 9 is connected with the discharge port 11 of the corresponding device, the material delivery port 10 is connected with the feed port 12 of the corresponding device, and the feed port 9 of the belt conveyor 7 is provided with a signal sensor 13, The discharge port 11 of the download test device 1 is also provided with a parts demagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com