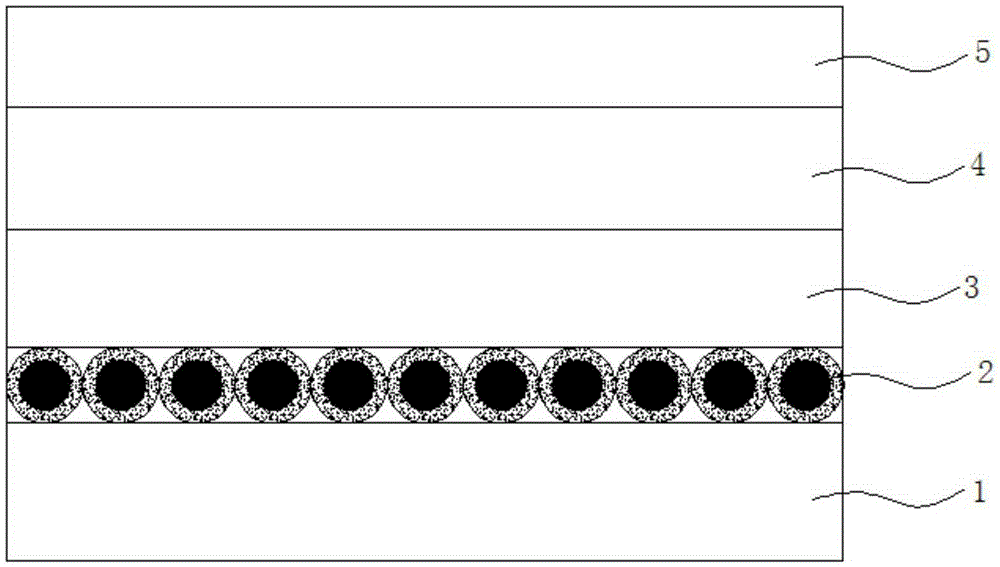

Perovskite solar cell structure and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of complex cell preparation process, limit the development of perovskite solar cells, and increase costs, achieve good electron transmission effect, compact structure, and avoid high temperature sintering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of perovskite solar cell structure in the present embodiment comprises the following steps:

[0035] (1) Clean the FTO conductive glass substrate with detergent earlier, then immerse the FTO conductive glass substrate after cleaning in the polydiallyldimethylammonium chloride aqueous solution with a volume concentration of 1%, soak for 30min; Finally, take out the FTO conductive glass substrate and repeatedly rinse with deionized water to remove excess polydiallyldimethylammonium chloride;

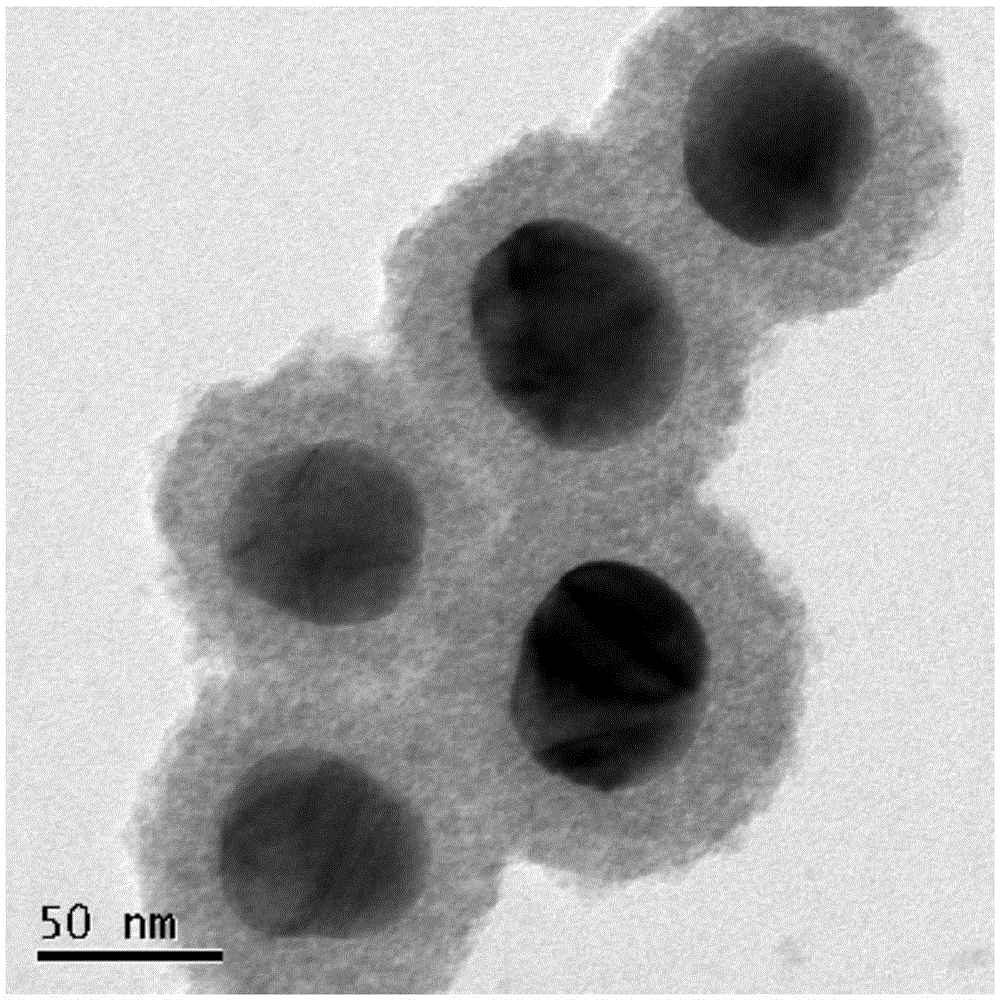

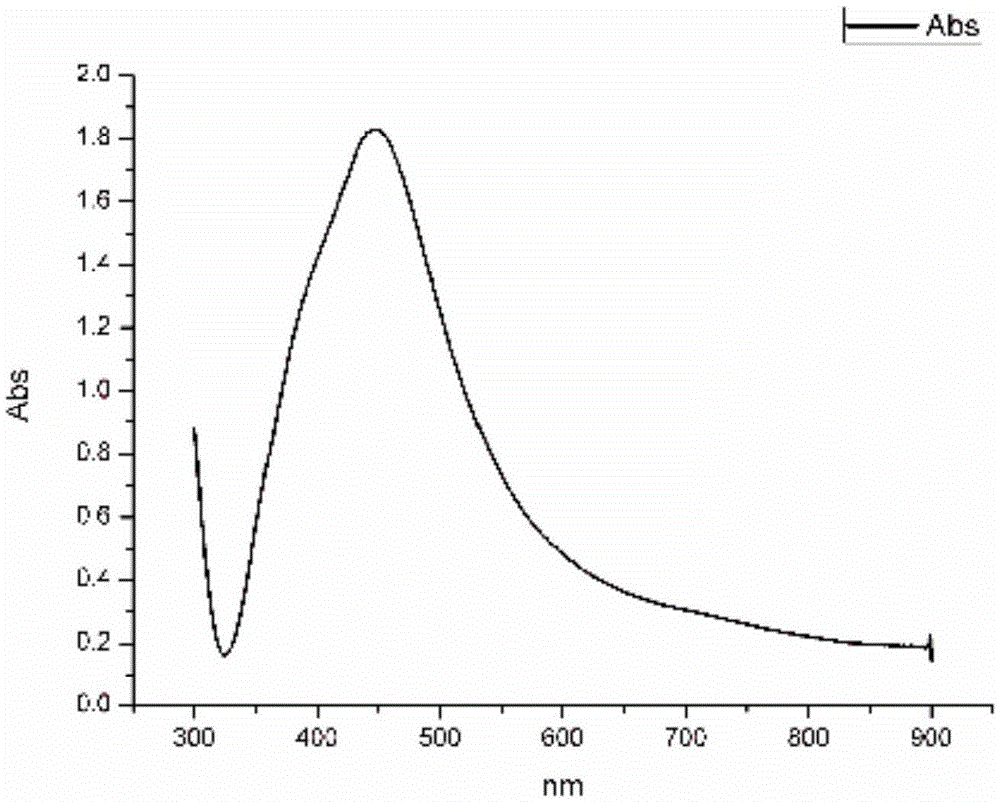

[0036] (2) At room temperature, the FTO conductive glass substrate obtained in step (1) is placed in AuTiO with a molar concentration of 0.01M and a solvent of ethanol. 2 Soak in the nano-solution for 24 hours. After soaking, take out the cathode transparent conductive substrate and dry it at 50°C for 24 hours, and place it in an anhydrous environment for later use; at this time, a layer of TiO2 is formed on the surface of the FTO conductive glass substrate. ...

Embodiment 2

[0041] The preparation method of perovskite solar cell structure in the present embodiment comprises the following steps:

[0042] (1) Clean the ITO conductive glass substrate with detergent first, then immerse the cleaned ITO conductive glass substrate in an aqueous solution of polydiallyldimethylammonium chloride with a volume concentration of 5%, soak for 10min; Finally, take out the cathode transparent conductive substrate and repeatedly rinse with deionized water to remove excess polydiallyldimethylammonium chloride;

[0043] (2) At room temperature, place the cathode transparent conductive substrate obtained in step (1) in an AgTiO solution with a molar concentration of 0.05M and a solvent of ether. 2 Soak in the nano-solution for 5 hours. After soaking, take out the cathode transparent conductive substrate and dry it at 60°C for 20 hours, and place it in an anhydrous environment for later use; at this time, a layer of TiO 2 Coated with the core-shell layer of Ag, the T...

Embodiment 3

[0049] The preparation method of perovskite solar cell structure in the present embodiment comprises the following steps:

[0050] (1) Clean the ITO conductive glass substrate with detergent first, then immerse the cleaned ITO conductive glass substrate in an aqueous solution of polydiallyldimethylammonium chloride with a volume concentration of 2.5%, soak for 20min; Finally, take out the cathode transparent conductive substrate and repeatedly rinse with deionized water to remove excess polydiallyldimethylammonium chloride;

[0051] (2) At room temperature, place the cathode transparent conductive substrate obtained in step (1) in AgTiO with a molar concentration of 0.025M and a solvent of ethanol. 2 Soak in the nano-solution for 15 hours. After soaking, take out the cathode transparent conductive substrate and dry it at 55°C for 22 hours, and place it in an anhydrous environment for later use; at this time, a layer of TiO 2 Coated with the core-shell layer of Ag, the TiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com