36-level high-precision capacitance and voltage adjusting transformer for distributing line

A voltage regulating transformer and power distribution line technology, applied in the direction of transformers, variable transformers, circuits, etc., can solve the problems of unbalanced voltage, single-phase voltage regulation, small capacity, etc., to reduce iron loss, ensure smoothness, The effect of reducing the magnetic density of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

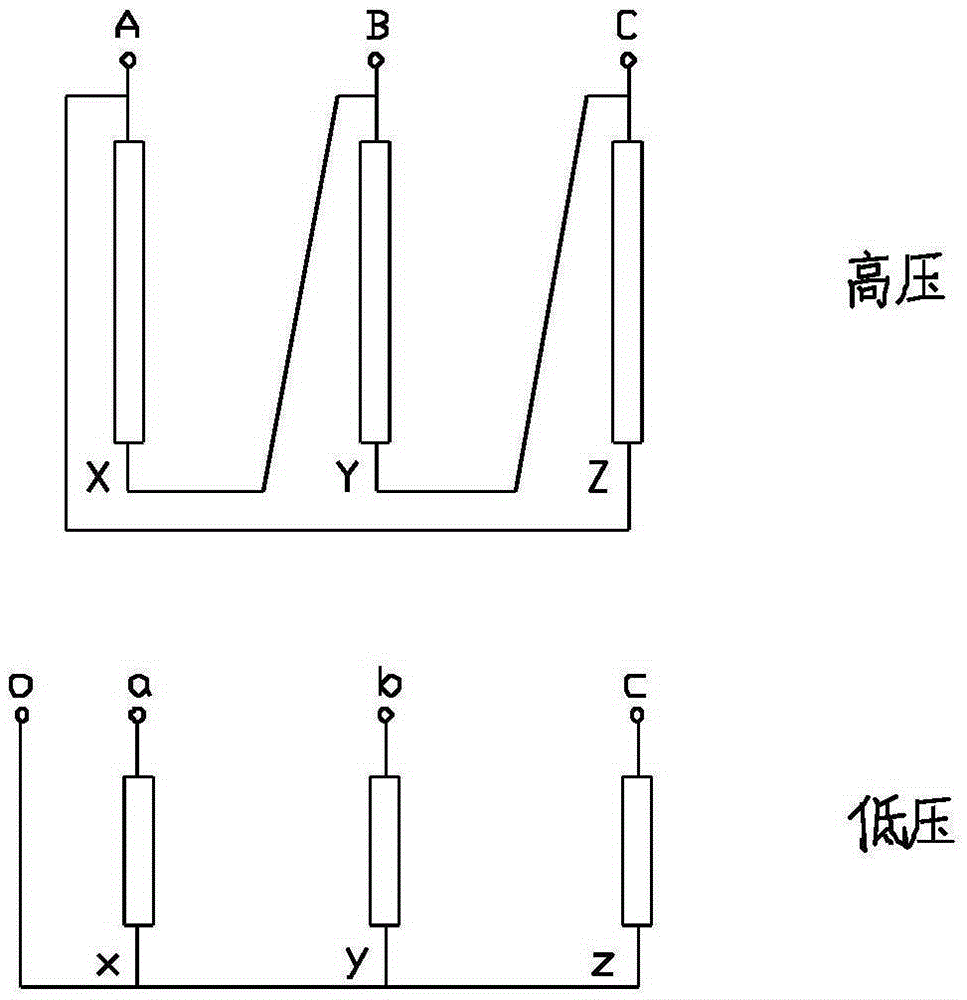

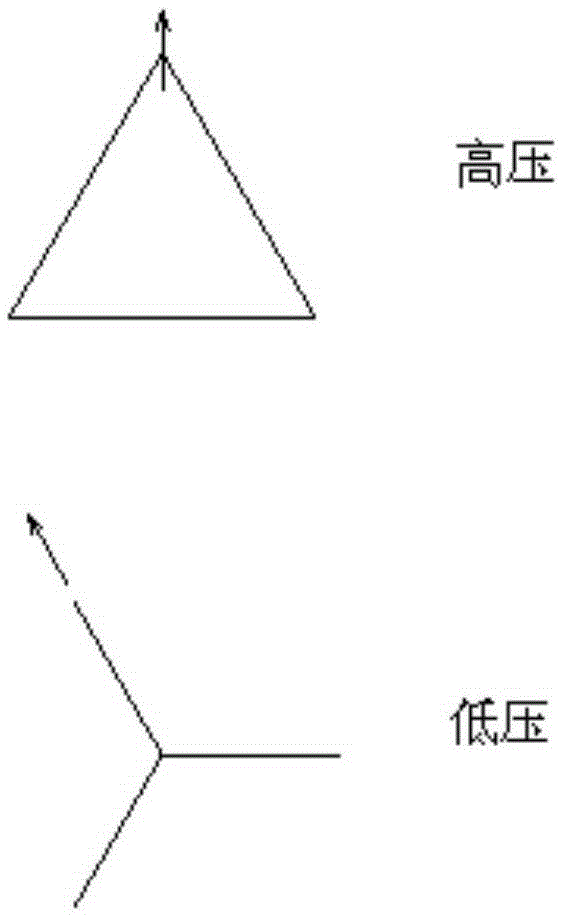

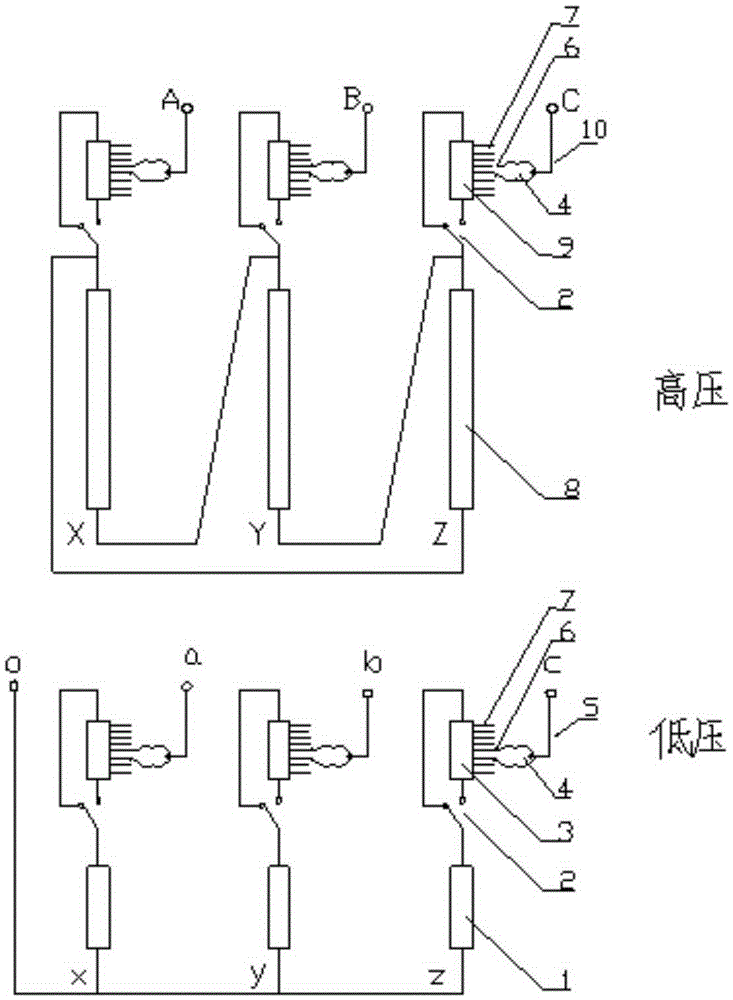

[0017] A 36-level high-precision power distribution line capacity-adjusting and voltage-regulating transformer, including low-voltage windings and high-voltage windings. The high-voltage side inputs 10kV voltage, and the low-voltage side outputs 400V voltage. The low-voltage winding adopts star connection method, and each phase is divided into low-voltage main winding 1 It is connected in series with the low-voltage regulating winding 3, the low-voltage main winding 1 and the low-voltage regulating winding 3, and each phase of the low-voltage regulating winding 3 is equipped with an on-load capacity regulating switch 5. The high-voltage winding adopts the Yanbian triangle connection method, and each phase is divided into high-voltage main winding 8 and high-voltage voltage regulating winding 9, wherein the high-voltage main winding 8 is connected in a triangle, and the high-voltage voltage regulating winding 9 is located between the apex of the triangle and the power supply end....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com