Optical axis verticality adjustment apparatus and adjustment method adopting same

A technology for adjusting device and verticality, applied in the field of visual measurement, can solve the problems of non-vertical and large error of measurement results, and achieve the effect of small calculation amount, reduction of verticality error and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

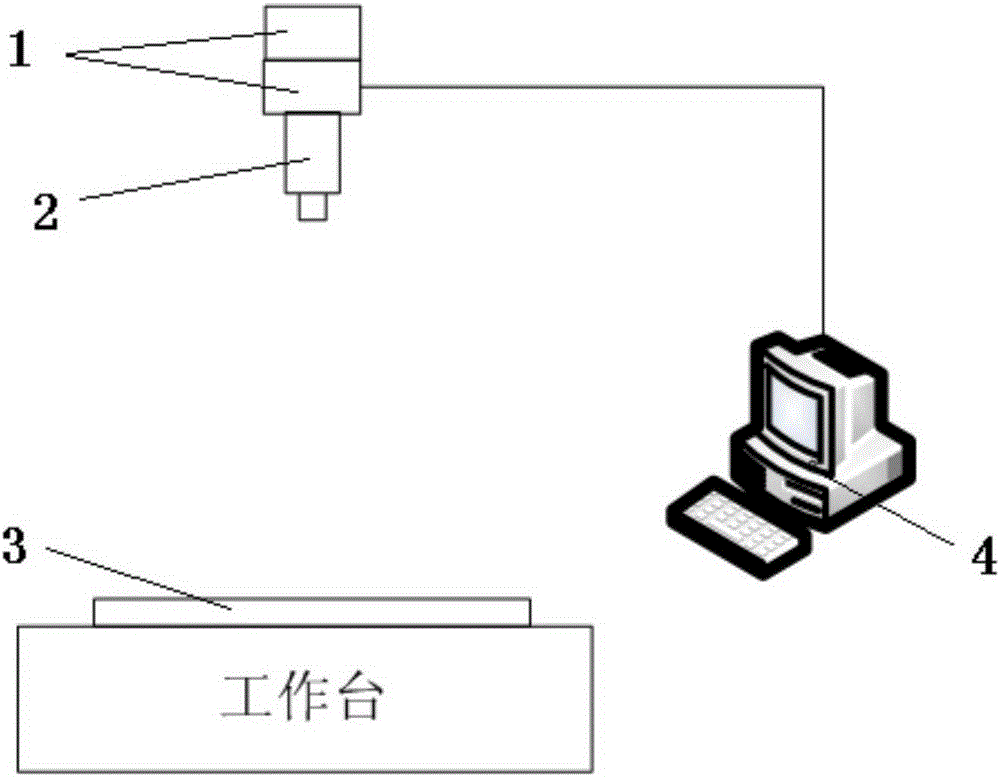

[0028] Such as Figures 1 to 5 shown. The optical axis verticality adjustment device of the present invention comprises an image processing system 4, an image acquisition module 2 (camera) fixed on the electric angle stage 1, and a workbench arranged below the image acquisition module 2; the electric angle stage 1 The image processing system 4 is connected with the image acquisition module 2 respectively; the image processing system 4 processes the images collected by the image acquisition module 2, and controls the movement angle of the electric angle stage 1.

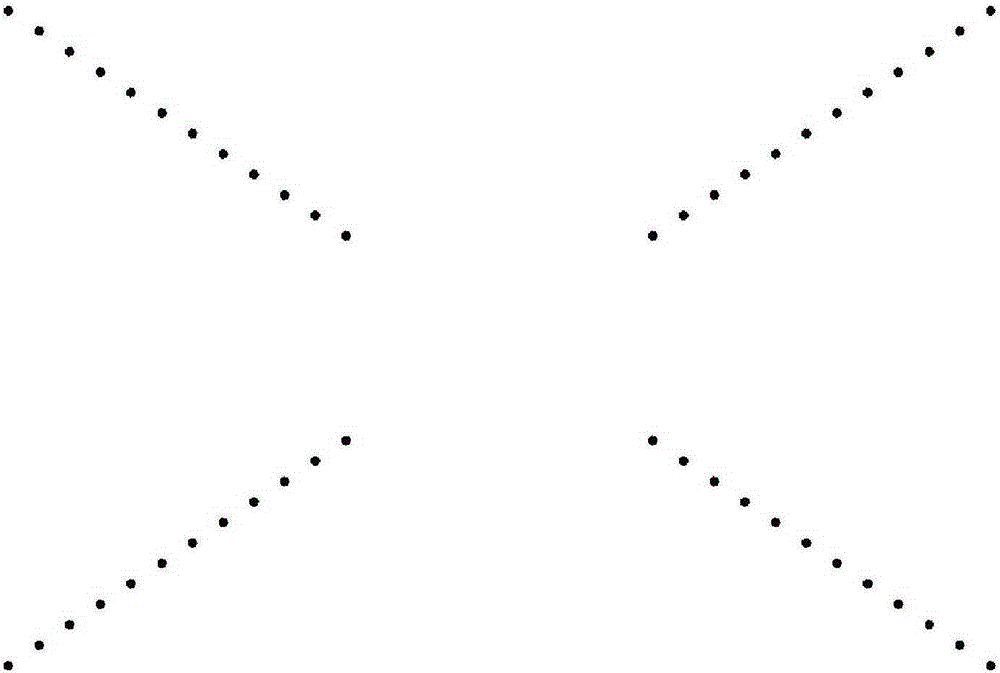

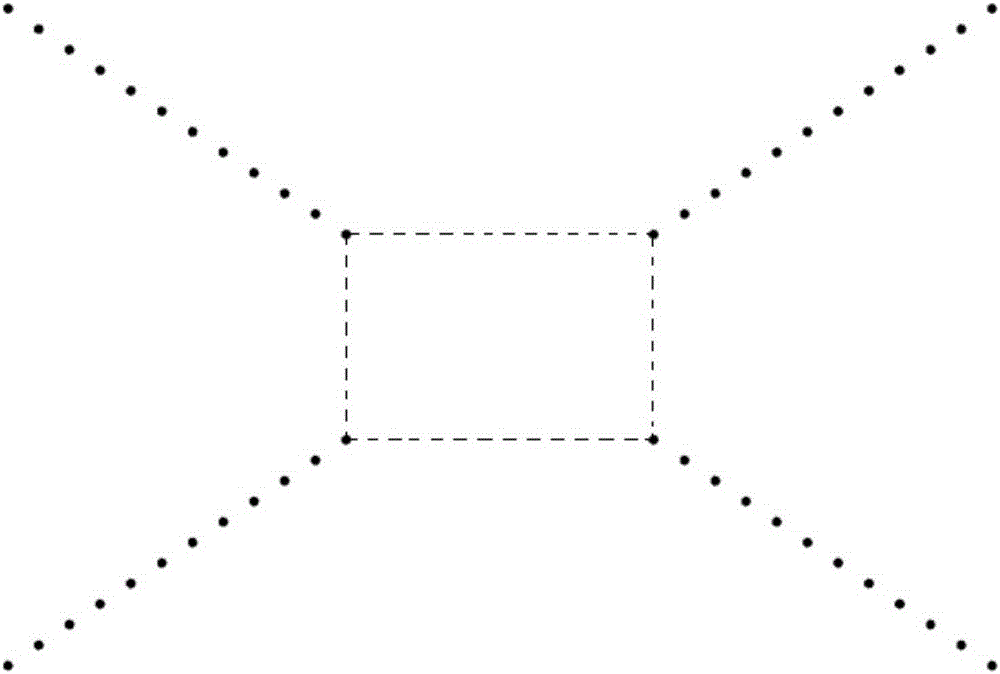

[0029] The workbench is used to place the round hole target 3, the base material of the round hole target 3 is optical flat glass, the round hole is coated with a round hole pattern, the round hole pattern is light-transmitting, and the base material is reflective. The flatness is less than 5um, the position accuracy of the circular hole pattern is less than 2um, and the roundness of the circular hole pattern is less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com