Cooling system of high water collecting tower

A cooling system and water collection tower technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems affecting peripheral circulating water cooling, small air flow resistance, improper matching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, and do not limit the protection scope of the present invention.

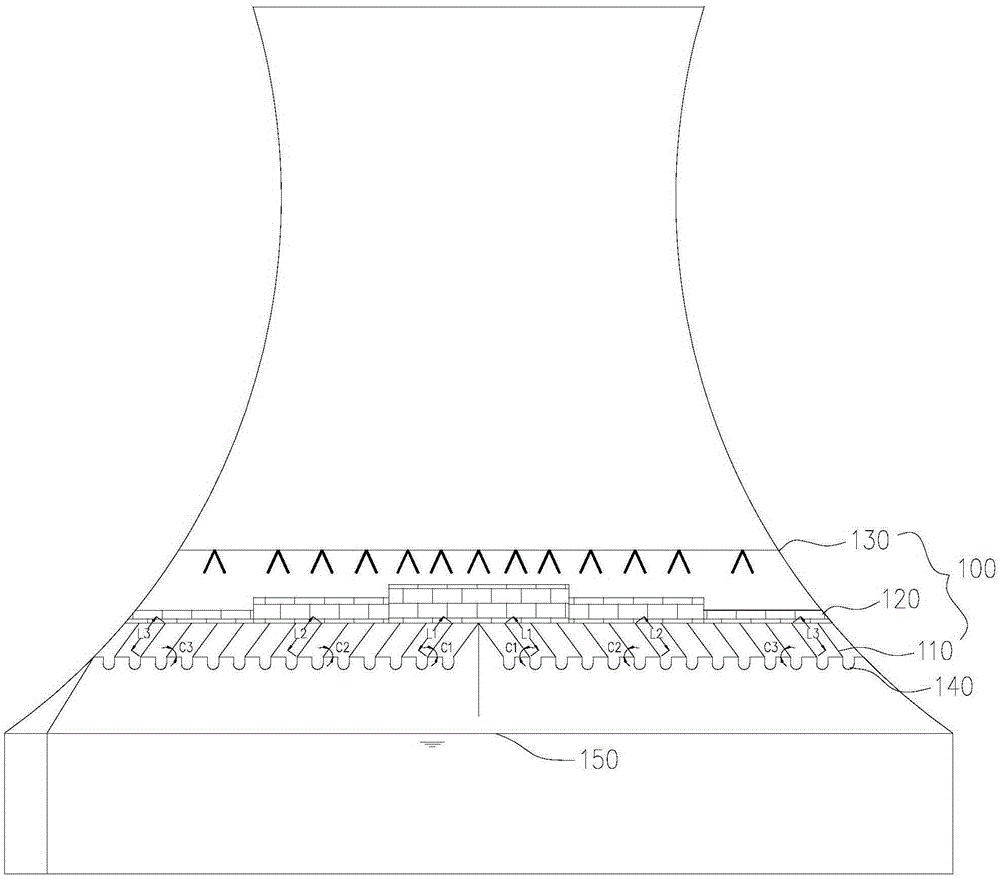

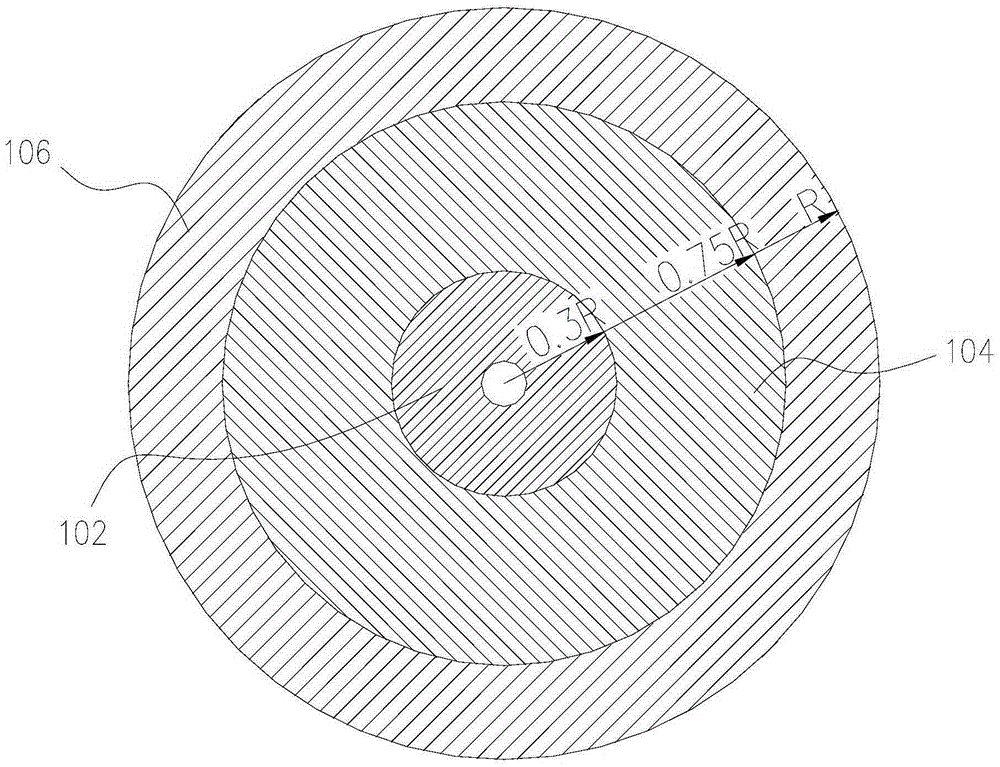

[0027] from figure 1 As shown, the cooling system of a high-level water collection tower according to the present invention includes a tower core device 100. The tower core device 100 takes the central axis of the high-level water collection tower as the center of the circle, and is divided into three annular distribution areas in turn: The inner area 102, the middle area 104 and the outer area 106, the tower core device 100 includes a packing device 120 and a water collection device 110; the packing device 120 includes a plurality of packing sheets (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com