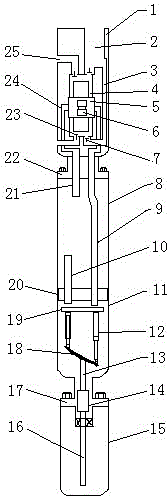

Well electric hydraulic conversion high-lift plunger pump

An electric and hydraulic technology for wells, applied in piston pumps, pumps, wellbore/well components, etc., can solve problems such as eccentric wear of rods and pipes, and achieve the effects of adapting to well conditions, reasonable and practical design, and prolonging the life of tubing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Power up the motor 15 to start, the motor shaft 16 drives the B pump shaft 13 to rotate through the coupling 14, the B pump plunger drive plate 18 installed on the B pump shaft 13 rotates, and drives the B pump plunger 12 to reciprocate, cylindrical The power oil in the power fluid tank 8 passes through the first power fluid nozzle 10, the B pump oil distribution plate 19, the B pump plunger 12, the B pump oil distribution plate 19, the power fluid pipe 9, the A pump power fluid pipeline 24, and the A pump power fluid pipeline 24. Pump plunger 5, A pump reversing valve 6, A pump power fluid pipeline 24, and second power fluid nozzle 21 return to the cylindrical power fluid tank 8; under the action of reversing valve 6, A pump plunger 5 goes up and down When the A pump plunger 5 moves up, the upper A pump drain valve 7 and the lower A pump inlet valve 23 are opened, the lower A pump drain valve 7 and the upper A pump inlet valve 23 are closed, and the working fluid works ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com