Super pressure suction joint pumping system and operating method thereof

A technology of super pumping pipes, which is applied in infrastructure engineering, construction, etc., can solve the problems of low vacuum pumping efficiency, high labor cost, and short service life of equipment in tube wells, so as to improve water collection efficiency and pumping efficiency, facilitate installation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

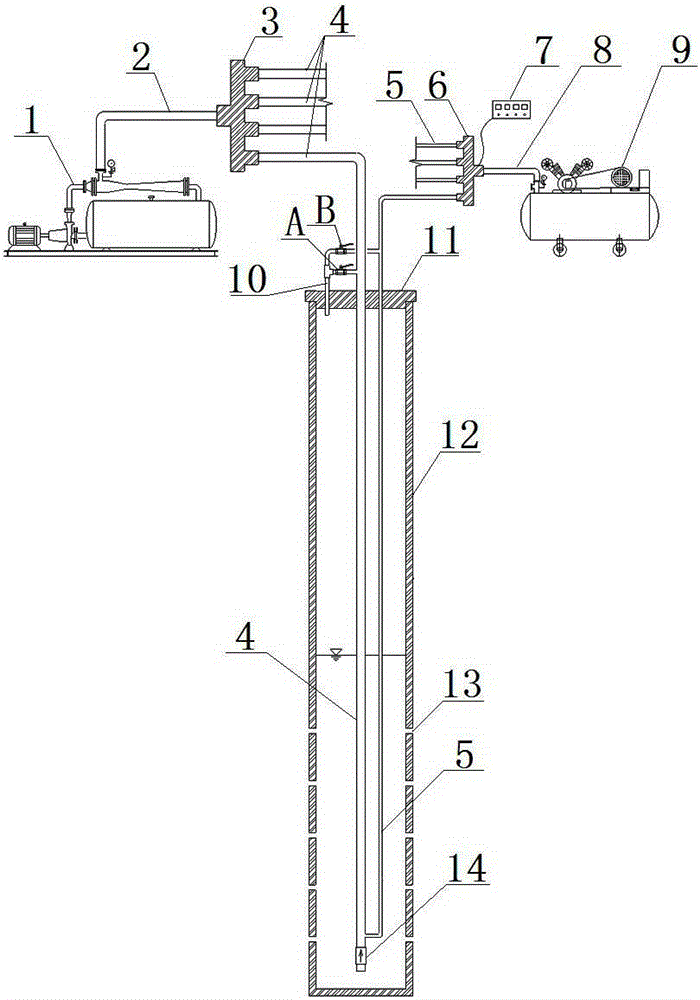

[0020] Embodiment 1: as figure 1 As shown, this embodiment specifically relates to a super pressure-suction combined pumping system and its working method. The pumping system mainly includes a downcomer well 12 , a vacuum pump 1 and an air compressor 9 .

[0021] The downfall tube well 12 is buried underground, and its upper port is slightly exposed on the ground. The downfall tube well 12 is provided with several filter holes 13 or gaps at different heights of the tube body according to the precipitation requirements of different strata, so as to serve as the channel for groundwater to enter the downfall tube well 12. The well cover 11 is sealed with the upper port of the downcomer well 12 to ensure the working efficiency of the tube well; on the well cover 11, there are also reserved communication ports for the suction pipe 4, the air pressure pipe 5 and the suction pipe 10 to run through.

[0022] The vacuum pump 1 is positioned on the ground outside the downcomer well 12, ...

Embodiment 2

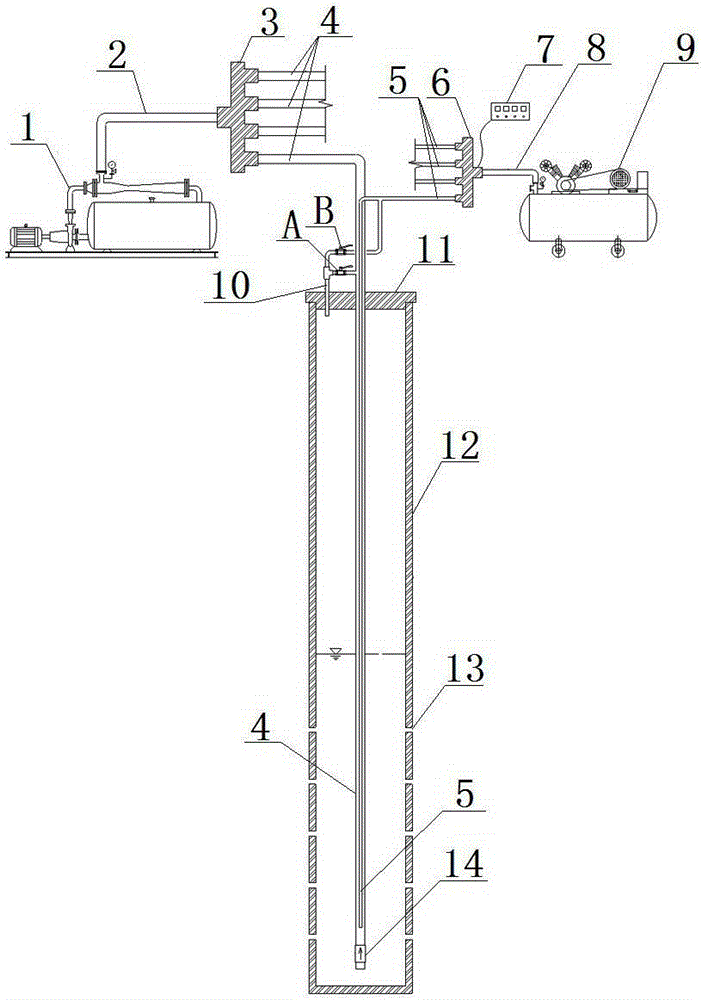

[0030] Embodiment 2: as figure 2As shown, this embodiment specifically relates to a super pressure-suction combined pumping system. The difference between this pumping system and the pumping system in Embodiment 1 is that the air pressure pipe 5 and the suction pipe 4 are arranged concentrically, specifically: Outside the downcomer well 12, the air pressure pipe 5 is connected to the water suction pipe 4 and extends into the water suction pipe 4. The two are arranged coaxially. It should be noted that the depth of the air pressure pipe 5 protruding into the water suction pipe 4 is adjustable.

[0031] When the pumping system is working, according to the observation results of the surrounding groundwater level observation wells, the extension length of the air pressure pipe 4 can be adjusted at any time to change the position of the lower port of the air pressure pipe 4, so as to avoid excessive water level difference and increase the air compressor 9 initial pressure, thus i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com