Vehicle front subframe

A front subframe and automobile technology, which is applied to vehicle components, substructures, transportation and packaging, etc., can solve the problems of poor anti-collision ability and the vehicle is difficult to meet the five-star collision requirements, and achieves good anti-collision ability and enhanced driving. and stiffness, ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

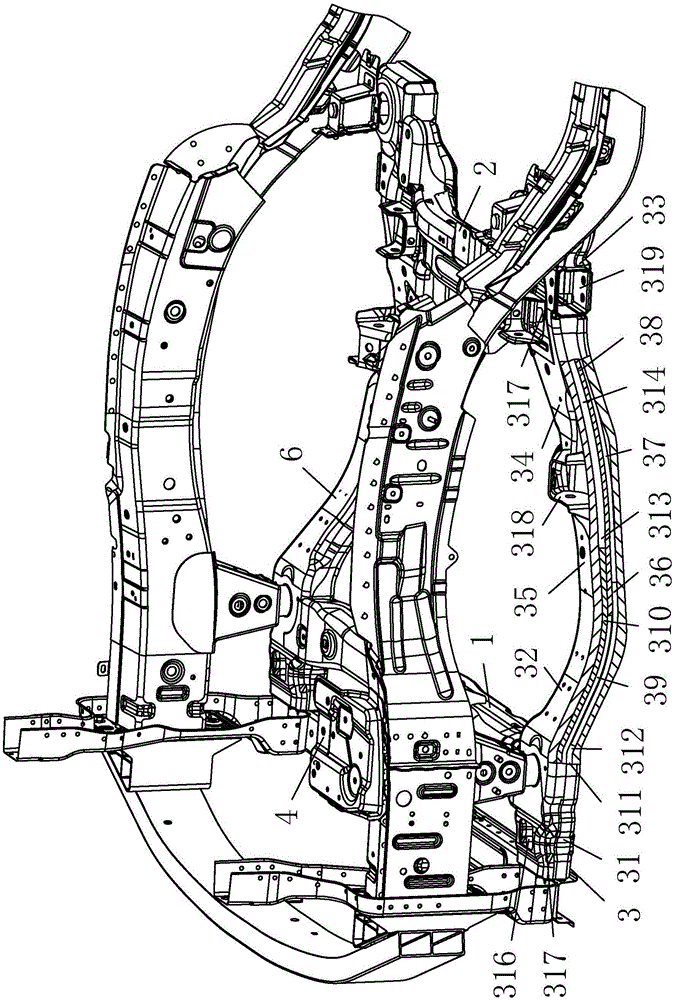

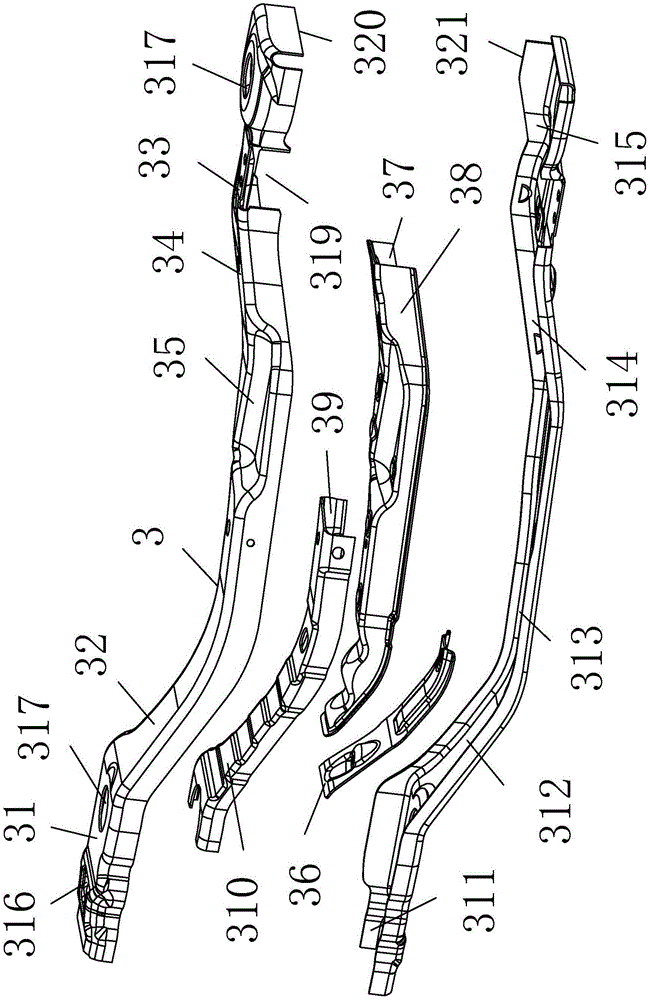

[0016] as attached figure 1 , attached figure 2 Shown: a front sub-frame of a car, including two symmetrically arranged side beams 3, a front beam 1 and a rear beam 2; the side beam 3 includes a front section 31, a front inclined section whose high end is connected to the rear end of the front section 31 32, the rear section 33, the rear oblique section 34 connecting the high end to the front end of the rear section 33, the middle section 35 connecting the two ends to the lower end of the front oblique section 32 and the lower end of the rear oblique section 34 respectively, the front lower energy-absorbing reinforcing plate 36, the bottom surface The rear energy-absorbing reinforcing plate 38 of the lower groove 37 whose width is transitionally matched with the width of the front lower energy-absorbing reinforcing plate 36 is provided, and the bottom surface is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com