Bow raising air source system of railway vehicle

A rail vehicle and air source technology, which is applied in the field of rail vehicle bow-raising air source system, can solve the problems of not compact enough structure, not firm enough installation, easy to cause air leakage, etc., and achieve compact and reasonable structure, reduce weight, and prevent air leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific examples. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

[0030] Example:

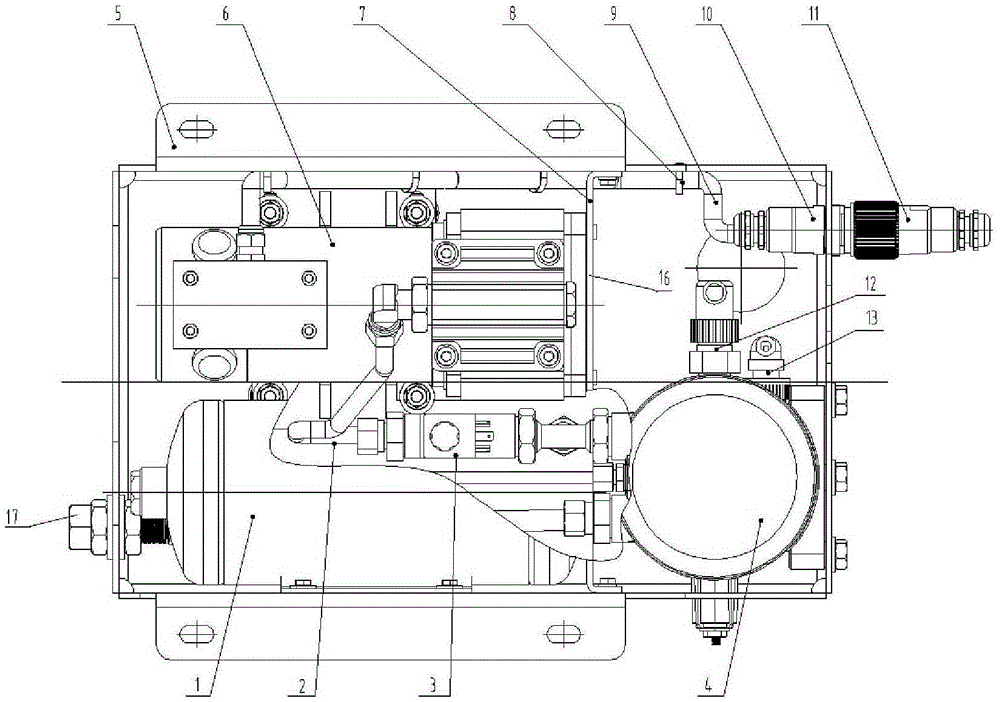

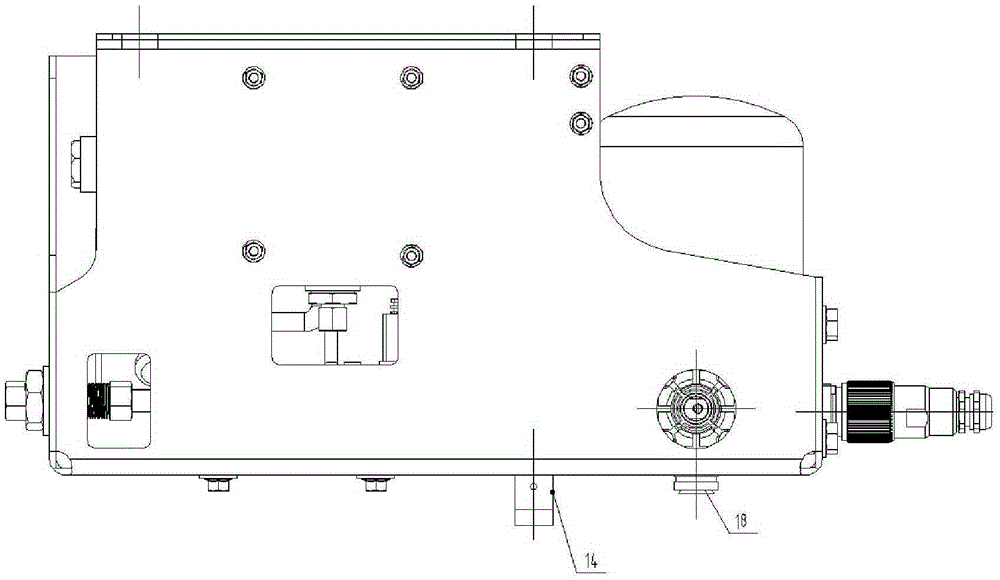

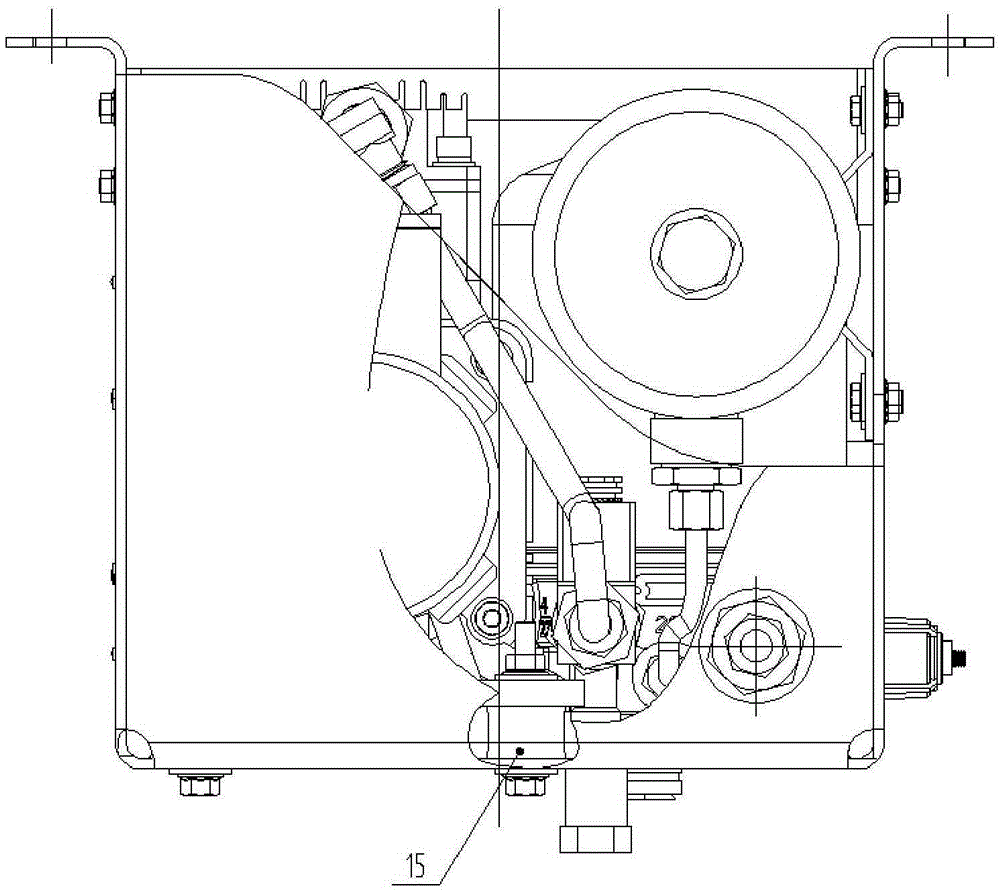

[0031] A rail vehicle bow lift wind source system, such as Figure 1 to Figure 5 As shown, the mounting frame 5 is included, and the mounting frame 5 is provided with an air compressor 6. One end of the air compressor 6 is connected to the socket 10 through the cable 9, the socket 10 is connected to the power supply through the plug 11, and the other end of the air compressor is connected through the The air guide pipe 2 is connected to the one-way solenoid valve 3, and the one-way solenoid valve 3 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com