Printing ink box nozzle antiblocking device

A technology for printing ink and nozzles, which is applied in the field of nozzle blocking devices for printing ink cartridges, and can solve the problems of inconvenient operation, unsatisfactory anti blocking effect, dry blocking of nozzles and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

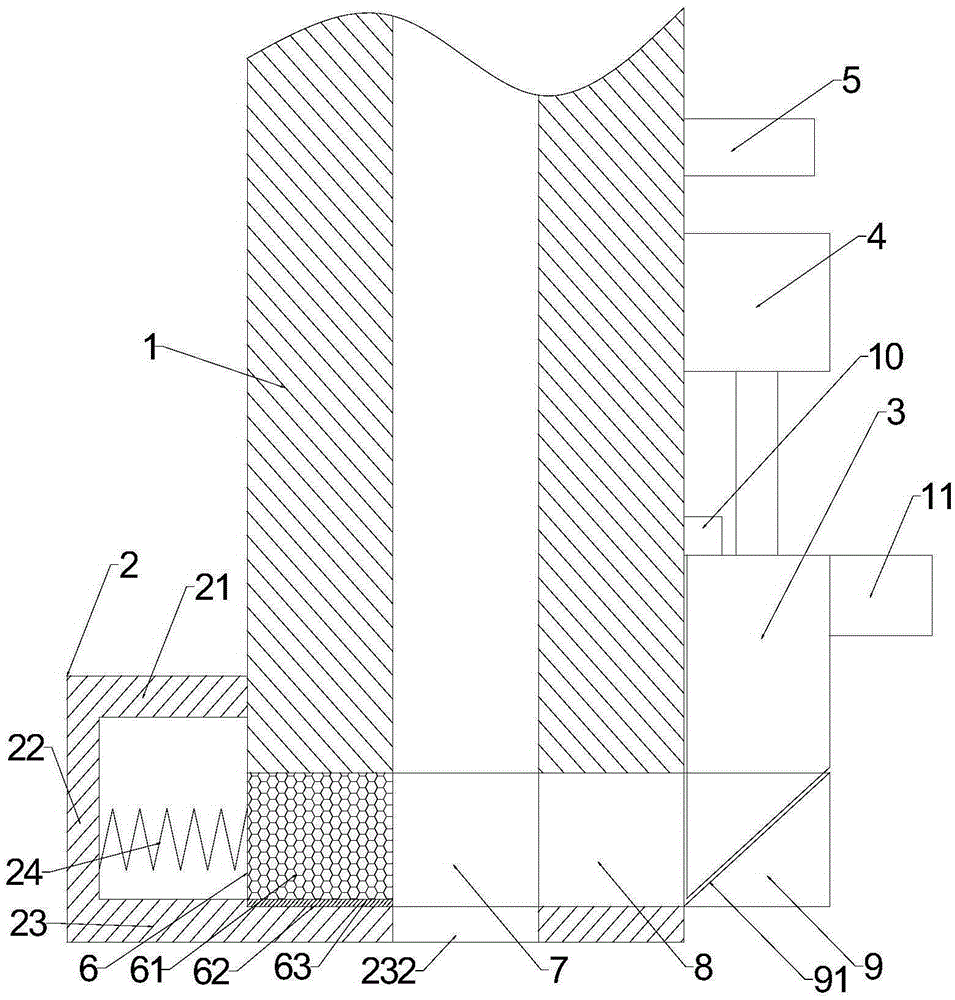

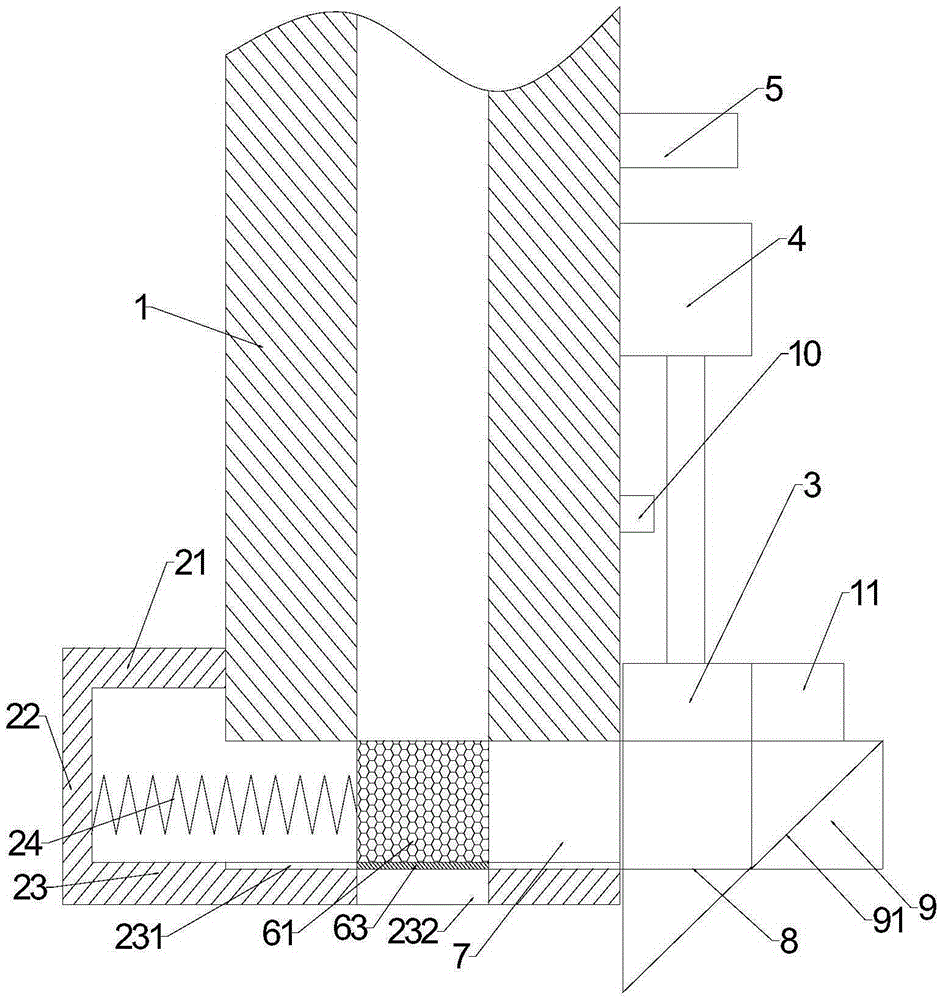

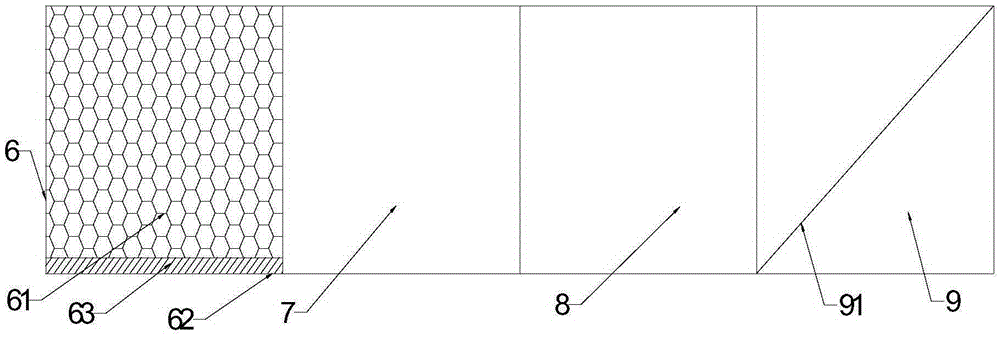

[0015] Depend on Figure 1 to Figure 4 It can be seen that the printing ink cartridge nozzle anti-blocking device of the present invention includes a baffle 2 fixed on the nozzle 1, an anti-blocking block, a push rod 3, a cylinder 4 and a controller 5, and the baffle 2 includes a connecting plate 21, a reset plate 22 and a guide Plate 23, the connecting plate 21 is fixed on the nozzle 1, the upper end of the reset plate 22 is fixedly connected with the connecting plate 21, and the lower end is fixedly connected with the guide plate 23, the reset plate 22 is fixedly provided with a spring 24, and the spring 24 is connected with the guide plate 23. The anti-blocking block is connected, the guide plate 23 is provided with a guide chute 231, and the guide plate 23 is provided with a first through hole 232 aligned with the nozzle 1, and the anti-blocking block is arranged in the guide chute 231, so The anti-blocking block is sequentially provided with a closed cavity 6, a second th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com