Modified adsorbent and application of same in preparation of ultra-pure hexafluoroethane

A technology of hexafluoroethane and adsorbent, applied in the field of modified adsorbent, can solve problems such as being unsuitable for industrial production, and achieve the effects of no secondary pollution, high adsorption efficiency, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

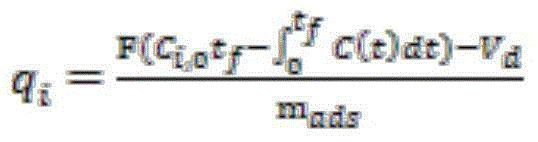

Method used

Image

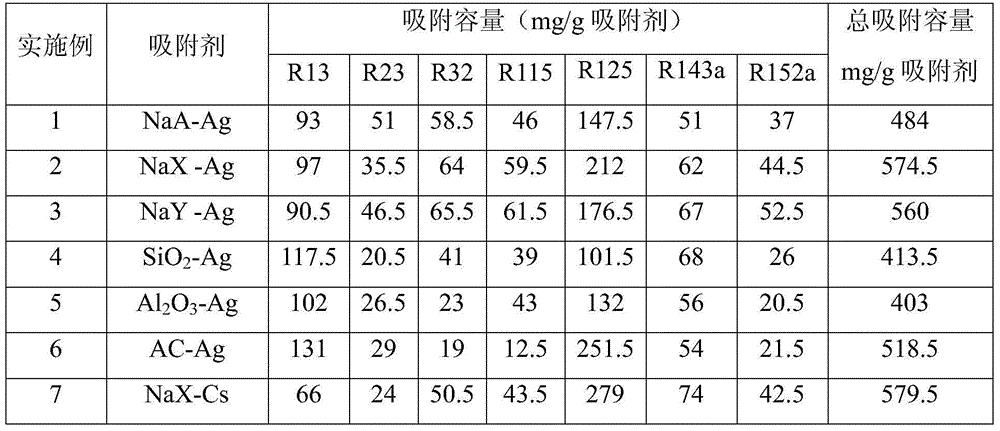

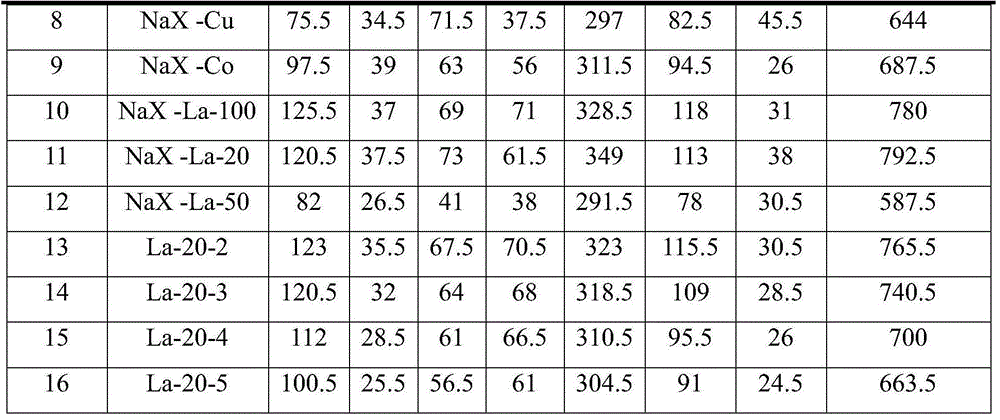

Examples

Embodiment 1

[0033] Weigh 10g of 4A (NaA) molecular sieve powder, and 0.1mol / L concentration of AgNO 3The solution was mixed at a solid-to-liquid ratio of 1:3, and stirred at 80°C for 4h. Filter molecular sieves, and add fresh AgNO at a concentration of 0.1mol / L again at a solid-to-liquid ratio of 1:3 3 The solution is ion exchanged. This process is repeated 4 times to ensure that Na + completely covered by Ag + Exchange, that is, the degree of exchange is 100%. Filter the solid and wash with distilled water until Ag-free + . Dry at 110°C for 8 hours. Take a certain amount of sample in the gas-solid phase adsorption device, at 350 ° C, N 2 Activate in situ in the atmosphere for 2 hours, and pass raw material gas hexafluoroethane to remove impurities after cooling down.

Embodiment 2-3

[0035] Weigh 10g13X (NaX) and NaY molecular sieve powder respectively, and mix with 0.1mol / L concentration AgNO 3 The solution was mixed at a solid-to-liquid ratio of 1:3, and stirred at 80°C for 4h. Filter molecular sieves, and add fresh AgNO at a concentration of 0.1mol / L again at a solid-to-liquid ratio of 1:3 3 The solution is ion exchanged. This process is repeated 4 times to ensure that Na + completely covered by Ag + Exchange, that is, the degree of exchange is 100%. Filter the solid and wash with distilled water until Ag-free + . Dry at 110°C for 8 hours. Take a certain amount of sample in the gas-solid phase adsorption device, at 350 ° C, N 2 Activate in situ in the atmosphere for 2 hours, and pass raw material gas hexafluoroethane to remove impurities after cooling down.

Embodiment 4

[0037] Weigh 10gSiO 2 and 20gAgNO 3 The solid was ground in a ball mill for 60 minutes, then taken out, and baked at 350°C for 8 hours to promote AgNO 3 in SiO 2 The surface is dispersed. Take a certain amount of sample in the gas-solid phase adsorption device, at 350 ° C, N 2 Activate in situ in the atmosphere for 2 hours, and pass raw material gas hexafluoroethane to remove impurities after cooling down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com