a chemical reaction kettle

A technology of chemical reaction kettle and frame, which is applied in the direction of chemical/physical/physical chemical fixed reactors, etc., can solve the problems of increasing reaction time, incomplete reaction, and reducing reaction efficiency, so as to reduce reaction time and heat The effect of rapid transmission and improvement of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

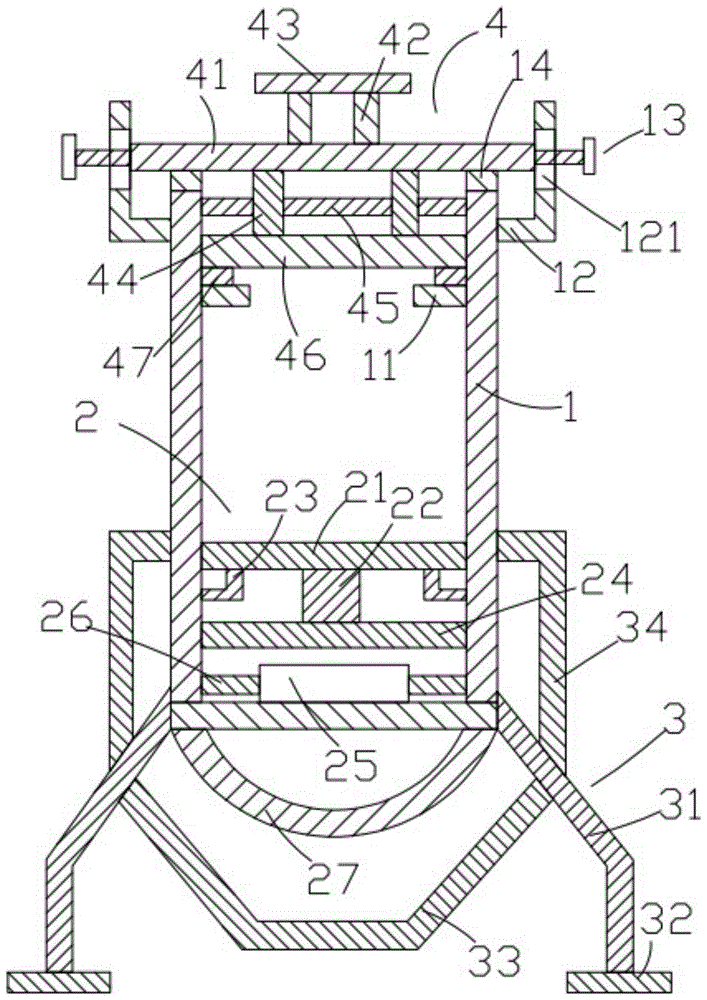

[0020] Such as figure 1 As shown, the chemical reaction kettle of the present invention includes a frame body 2 , a heating device 2 inside the frame body, a support device 3 below the frame body, and a cover plate device 4 above the frame body.

[0021] Such as figure 1 As shown, the frame body 1 includes first fixing blocks 11 located on the left and right sides inside the frame body 1, fasteners 12 located outside the frame body 1, and first fixing blocks 12 located on the sides of the fasteners 12. The rectangular hole 121, the fixing member 13 located in the first rectangular hole 121 and the sealing ring 14 located on the upper surface of the frame body 1, the frame body 1 is a hollow cylinder, and the frame body 1 is placed vertically , the first fixed block 11 is horizontal, the first fixed block 11 is provided with two and located on the left and right sides respectively, the first fixed blocks 11 located on the left and right sides are at the same height, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com