Juicer

A juicer and juicing technology, applied in the field of kitchen utensils, can solve problems such as insufficient juice yield, insufficient juicing speed, and inability to successfully complete juicing, and achieve the effects of convenient cleaning and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

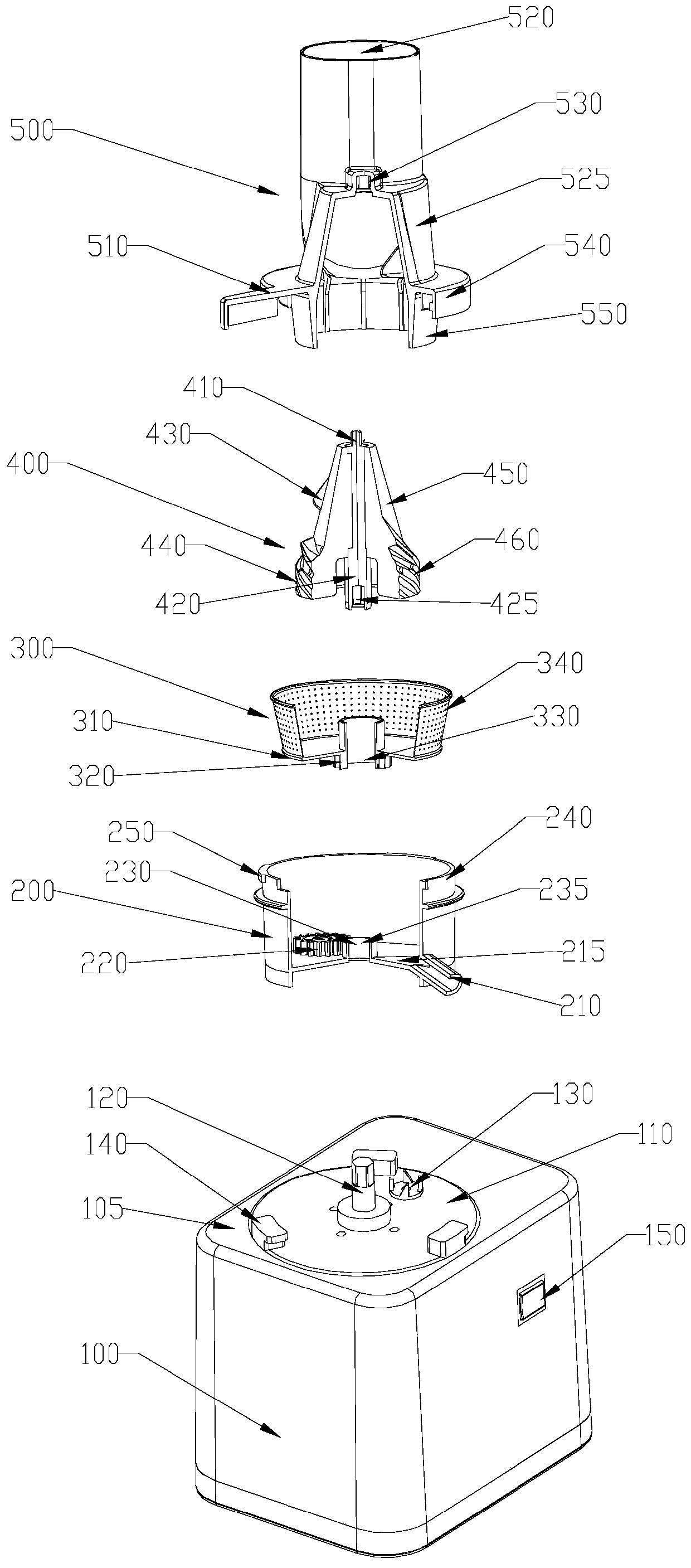

[0071] figure 1 and Figure 2a , Figure 2b Shown is a schematic structural view of the juice extractor in Embodiment 1 of the present invention. The juice extractor includes: a base 100, a housing 200, a filter basket 300, a juice extraction head 400 and a top cover 500, wherein the top surface 105 of the base 100 There is a support surface 110 for installing the housing 200 , on which three buckles 140 arranged along the circumferential direction are arranged on the support surface 110 . The shown first driving mechanism 120 and the second driving mechanism 130 are installed in the base 100 , and the output shaft of the first driving mechanism 120 protrudes from the through hole in the middle of the supporting surface 110 .

[0072] continue to see figure 1 and Figure 2a , Figure 2b , the top of the housing 200 is provided with an opening 240 , the outer surface of the opening 240 is provided with a plurality of second position-limiting protrusions 250 , and the botto...

Embodiment 2

[0078] like Figure 4a , Figure 4b As shown, in embodiment 2, the juice extraction head is a screw type juice extraction head, which includes:

[0079] The guide shaft 410 is arranged in the middle of the upper end face of the screw-type juicing head;

[0080] The driving connecting shaft 420 is formed by protruding downward from the lower end of the screw type juice extracting head, and the driving connecting shaft is connected with the driving mechanism;

[0081] Grinding the main body 440, which is the main body of the screw;

[0082] Multi-channel screw helix, which is protrudingly formed on the outer surface of the screw main body; the screw main body of the juice extraction head adopts a cone structure with the small end facing upwards, and a crushing knife 430 is formed on the top of the screw cone, and the outer surface of the screw helix The height of the surface protruding from the main body of the screw decreases gradually from top to bottom to form a grinding p...

Embodiment 3

[0091]In Embodiment 3, the structure of the shell of the juicer can be simplified, the juice outlet port is subtracted, the juice is stored in the shell, and the juice is poured out after the juice is squeezed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com