Control device and control method

A control device and control method technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve the problems of large volume of position sensor, complex structure of the whole motor, poor anti-disturbance ability, etc., and achieve detection High precision, improve the efficiency and stability of the whole machine, and the effect of small space structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In view of the technical problems of complex structure, unstable performance and high cost of the whole motor when the position sensor is used to detect the position of the rotor in the drive technology of the ironless disc motor in the prior art, the present invention proposes the use of the rotorless position sensor Control technology is used to detect the position of the rotor, thereby avoiding the above-mentioned technical problems in the prior art, improving the reliability of the performance of the motor as a whole, and reducing the cost.

[0048] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

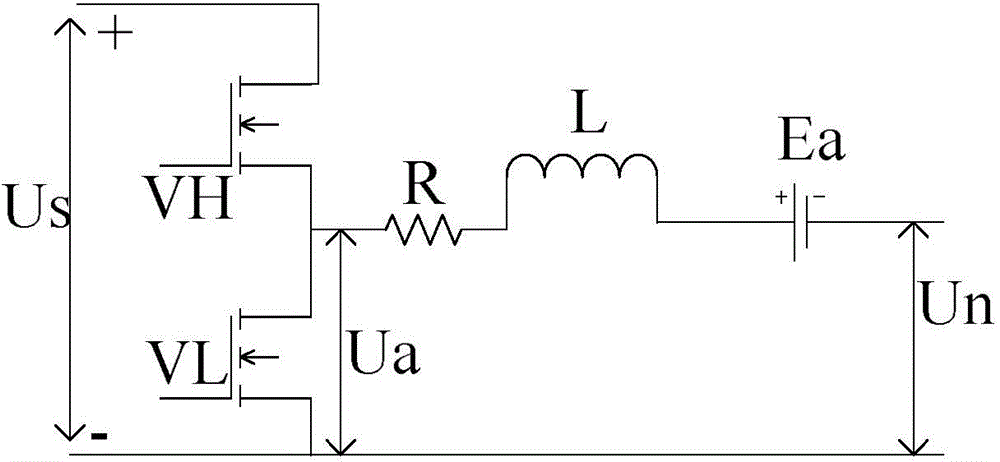

[0049] See figure 1 , which is a schematic structural diagram of a control device for controlling a motor provided by an embodiment of the present invention.

[0050] The control device, used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com