Charging method for improving charging efficiency of lithium ion battery

A lithium-ion battery, charging efficiency technology, applied in secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve problems such as reducing charging efficiency, and achieve the effect of improving charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a positive electrode is made of LiFePO 4 (Material 1, mass percent w=90%) and LiMn 2 o 4 (Material 2) A lithium-ion battery (hereinafter referred to as 1-1 battery) composed of two (i=2) active materials is charged. 1-1 In the battery, the mass ratio of the two materials is LiFePO 4 : LiMn 2 o 4 =9:1. The reference battery of the two materials is: the positive electrode material is only LiFePO 4 (hereinafter referred to as 1-2 battery), and the positive electrode material is only LiMn 2 o 4 (hereinafter referred to as 1-3 batteries). The manufacturing process of the three batteries is exactly the same.

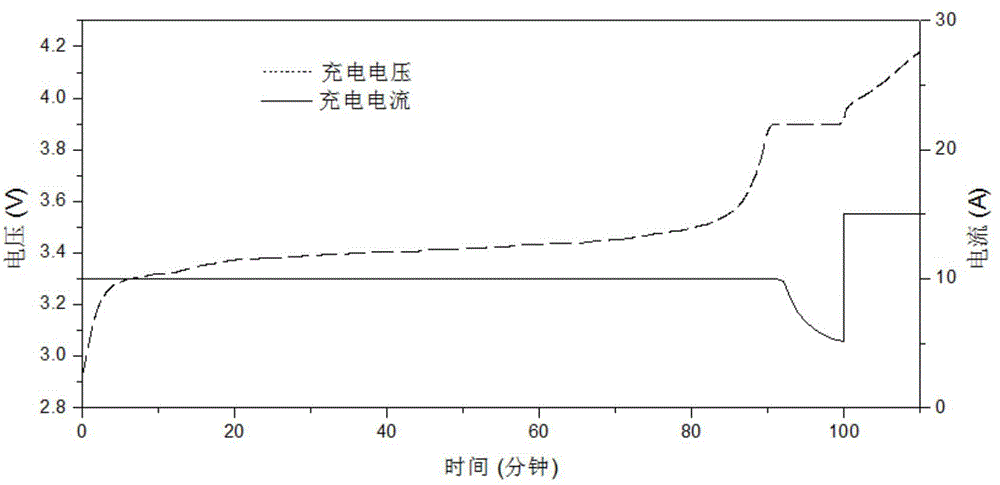

[0030] Charge the 1-1 battery with the following standard charging method to determine the battery capacity: charge at 4A constant current to 4.2V, then switch to constant voltage charging at 4.2V, and the charging cut-off current is 0.4A. It is obtained that the battery capacity is 20.1Ah, and the current corresponding rate of constant cur...

Embodiment 2

[0039] In this embodiment, a positive electrode is made of Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 (Material 1) and LiMn 2 o 4(Material 2) A lithium-ion battery composed of two active materials (hereinafter referred to as 2-1 battery) is charged. In the 2-1 battery, the material mass ratio is material 1: material 2 = 20:80. Reference battery: the positive electrode material is only Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 (hereinafter referred to as 2-2 battery), and the positive electrode material is only LiMn 2 o 4 (hereinafter referred to as 2-3 batteries). The manufacturing process of the three batteries is exactly the same.

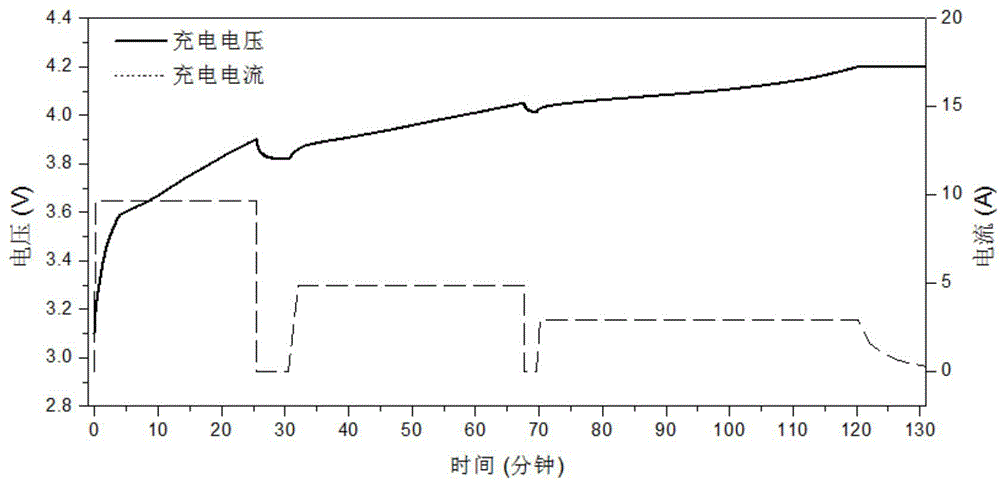

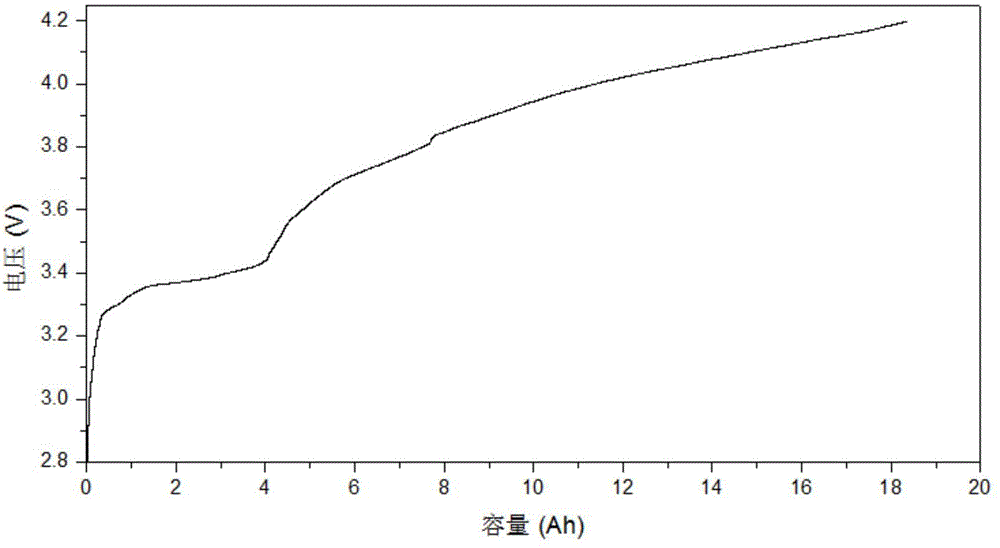

[0040] Charge the 2-1 battery with the following standard charging method to determine the battery capacity: charge with a constant current of 2A to 4.2V, then charge with a constant voltage at 4.2V, and the charging cut-off current is 0.2A. It is obtained that the battery capacity is 9.9Ah, and the constant current charging current corresponds to a rate of 0....

Embodiment 3

[0049] In this embodiment, a positive electrode is made of LiFePO 4 (Material 1), Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 (Material 2), LiMn 2 o 4 (Material 3) A lithium-ion battery composed of three active materials (hereinafter referred to as 3-1 battery) is charged. The mass ratio of the three materials is 1:1:3. Reference battery: the positive electrode material is LiFePO only 4 (hereinafter referred to as 3-2 battery), the positive electrode material is only Li(Ni 1 / 3 co 1 / 3 mn 1 / 3 )O 2 (hereinafter referred to as 3-3 battery), the positive electrode material is only LiMn 2 o 4 (hereinafter referred to as 3-4 batteries). The manufacturing process of the four batteries is exactly the same.

[0050] Charge the 3-1 battery with the following standard charging method to determine the battery capacity: charge with a constant current of 4A to 4.2V, then charge with a constant voltage at 4.2V, and the charging cut-off current is 0.4A. The battery capacity is obtained as 20.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charging efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com