Preparation method for nanometer graded porous carbon material used for high-performance electrochemical supercapacitor based on rice hull ash

A technology of supercapacitor and graded porous carbon, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of environmental pollution and resource waste, and achieve a large specific surface area, save resources, and be conducive to environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

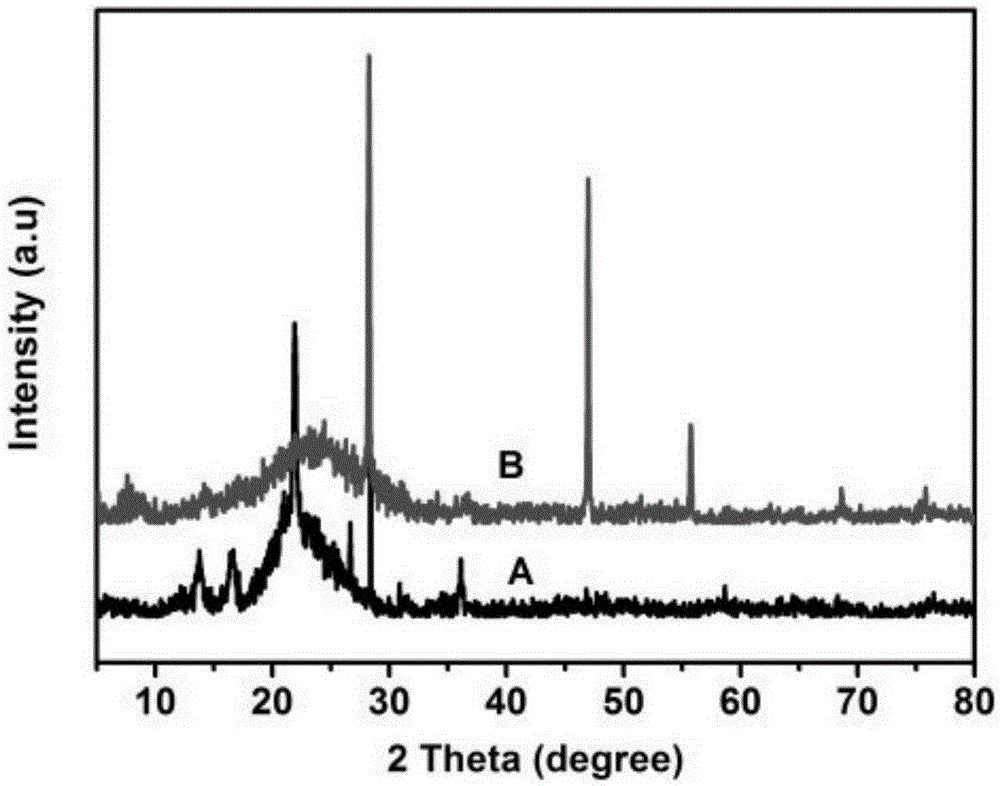

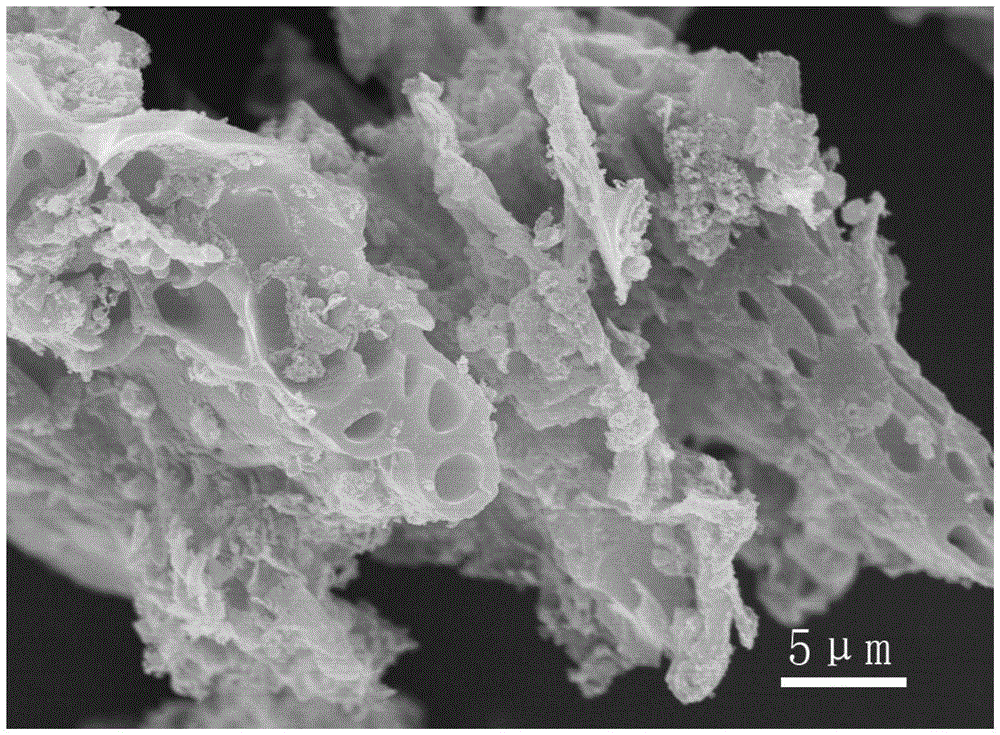

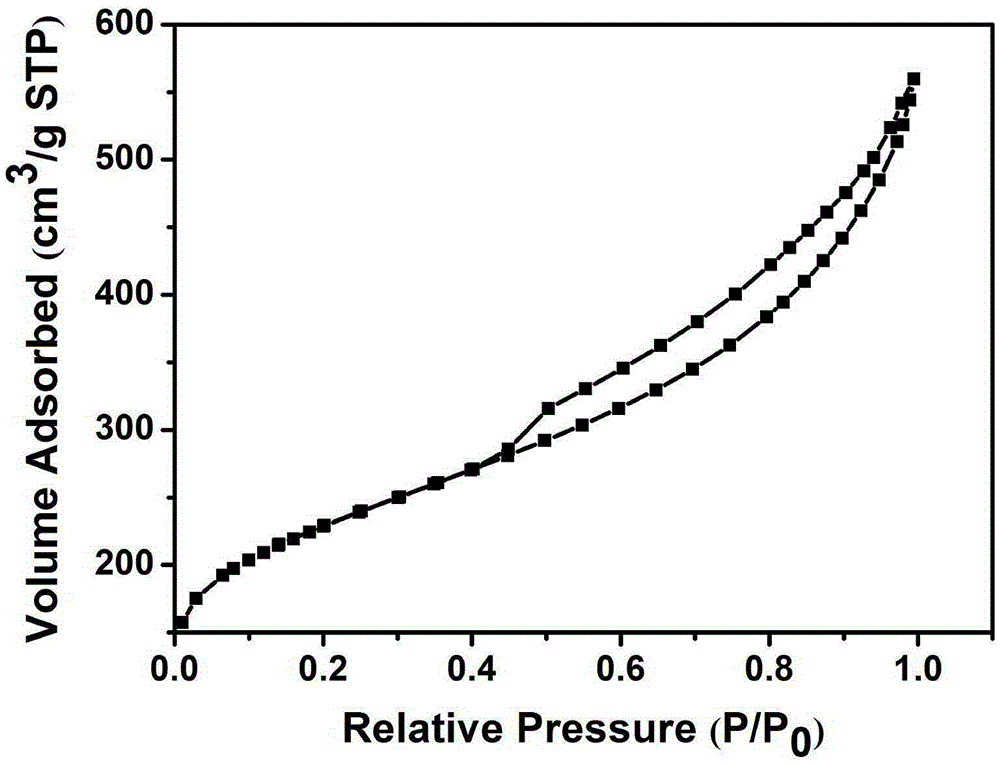

[0019] Embodiment 1: A method for preparing a nanoscale porous carbon material for high-performance electrochemical supercapacitors based on rice husk ash in this embodiment, specifically operates according to the following steps:

[0020] 1. Add rice husk ash to hydrofluoric acid under stirring conditions, and stir evenly to obtain a suspension; wherein, the volume concentration of hydrofluoric acid is 1% to 10%, and the stirring time is 12 to 24 hours;

[0021] 2. Wash the suspension obtained in step 1 with distilled water, and then dry it. The drying process is as follows: place it in a vacuum drying oven, and dry it at a temperature of 50-80°C for 12-24 hours;

[0022] 3. Add KOH to the sample obtained after drying in step 2 for activation, and carbonize in a tube furnace; wherein, the mass ratio of the sample to KOH is 1: (1-5), the activation temperature is 600-1000°C, and the holding time is 1~2h;

[0023] 4. Repeatedly wash the carbonized sample obtained in step 3 wit...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that: the volume concentration of hydrofluoric acid in step 1 is 2% to 10%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the mixing and stirring time of hydrofluoric acid in step 1 is 12-20 hours. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com