A new type of temperature sensor

A temperature sensor, a new type of technology, applied in thermometers, thermometer parts, instruments, etc., can solve problems such as the lack of real reflection of the temperature of the cooker, the influence of the use of the cooker, and the drift of the temperature curve, so as to reduce unfavorable factors and facilitate The effect of high precision in assembly and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

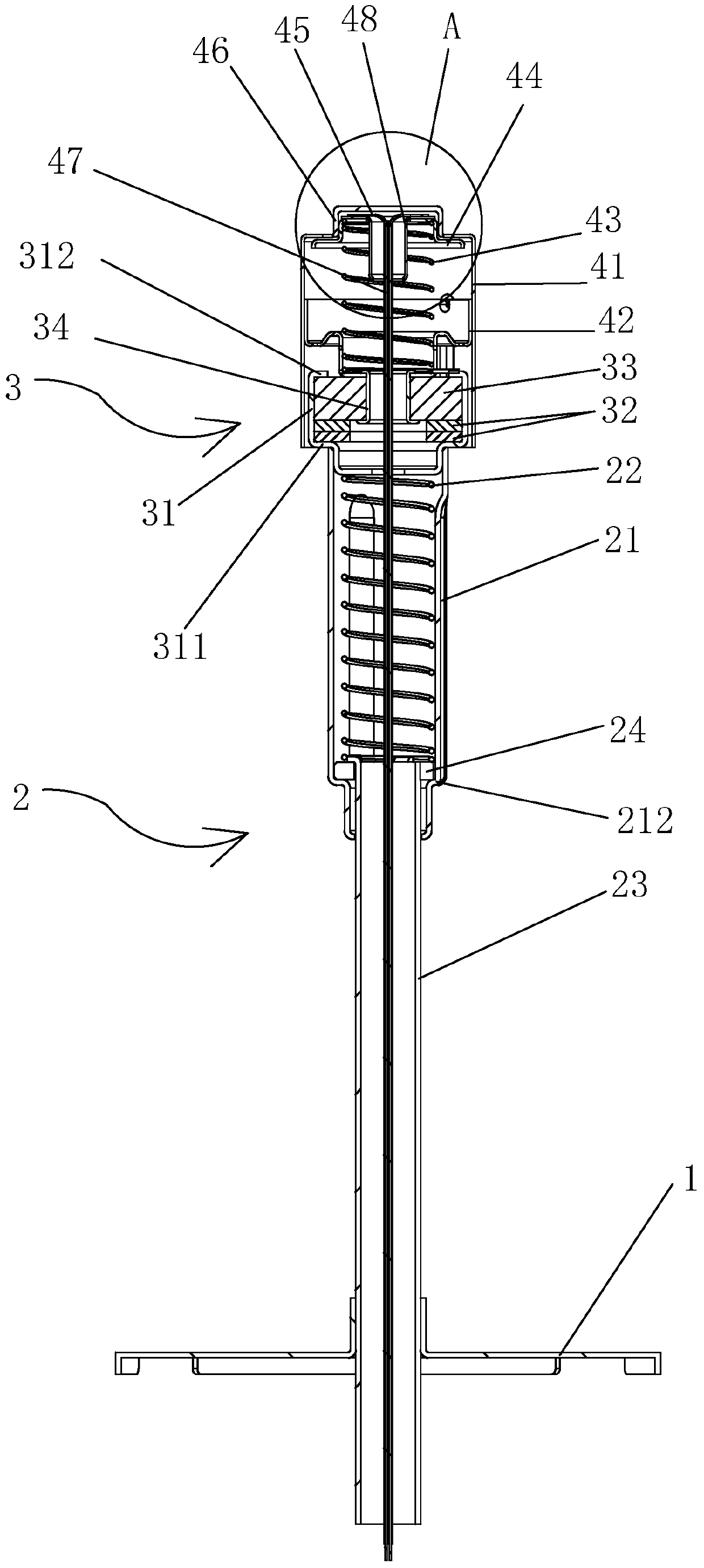

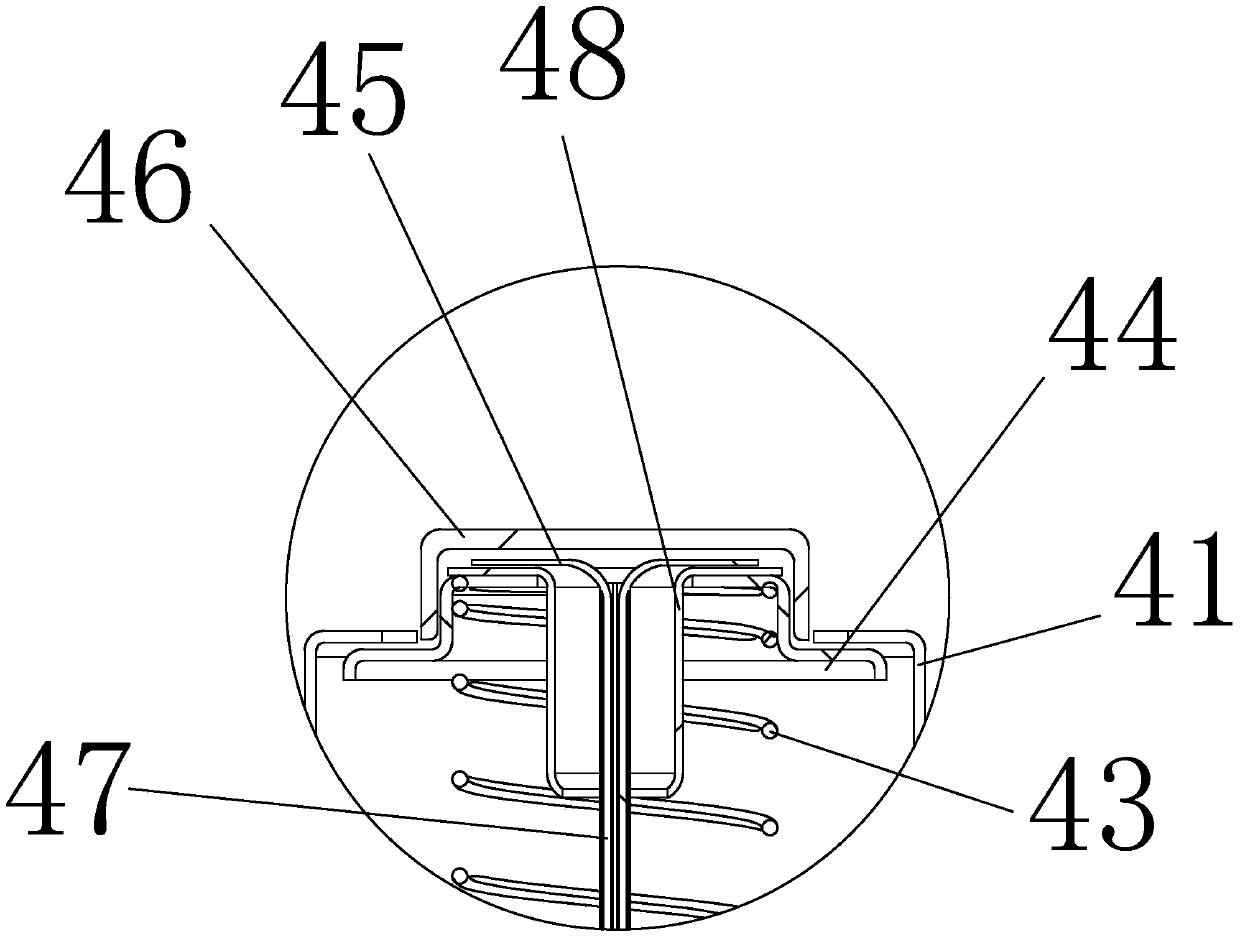

[0039] Such as Figure 4 As shown, the probe seat 44 is pressed inside the bushing 41, so that the spring seat 42, the probe seat 44, and the bushing 41 form a cavity structure. In the free state of the non-working state, the probe seat 44 in the cavity is closely attached to the upper end surface of the bushing 41 under the action of elastic force to prevent the intrusion of foreign oil, smoke and other sundries. In the working state, the high-temperature heating pot body, the bottom of the pot presses the probe 46, the probe base 46 is separated from the upper surface of the bushing 41, the probe 46 is flattened with the bottom of the pot so as to independently sense the temperature of the bottom of the pot, and the inner wall of the bushing 41 separates the probe 46 inside from the outside world , prevent external high temperature conduction in the transverse direction, and radiate to the probe seat 42, wire seat 48 and probe 46 in the cavity; the glass-ceramic 33 and the g...

Embodiment 2

[0041] Such as Figure 11 and Figure 12 As shown, the bushing 41 is provided with an outer cover.

[0042] Such as Figure 12As shown, the probe seat 44 is pressed in the bushing 41, so that the spring seat 42, the probe seat 44, the bushing 41 and the outer cover of the sliding sleeve form two cavity structures. The inner cavity and the outer cavity are free in the non-working state. Next, the probe seat 44 in the inner cavity and the upper end surface of the sliding sleeve cover are tightly fitted under the action of the spring force to prevent foreign oil, smoke and other sundries from invading. The bottom presses the probe 46, the probe base 44 is separated from the outer cover of the sliding sleeve, and the probe 46 is flattened with the bottom of the pot so as to sense the temperature of the bottom of the pot independently. Radiation to the inner cavity; glass ceramics 33 and glass fiber sheet 32 prevent the conduction of temperature in the longitudinal direction; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com