Multi-effect hot air drying tower

A hot air drying, multi-efficiency technology, applied in the field of drying towers, can solve the problems of high thermal energy consumption, low heat conversion rate, large volume, etc., and achieve the effect of reducing processing costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

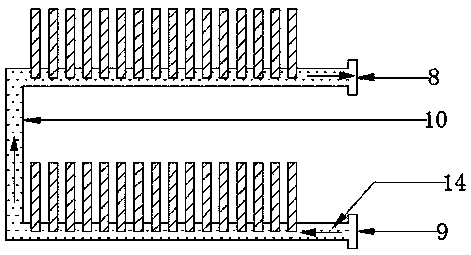

Image

Examples

Embodiment Construction

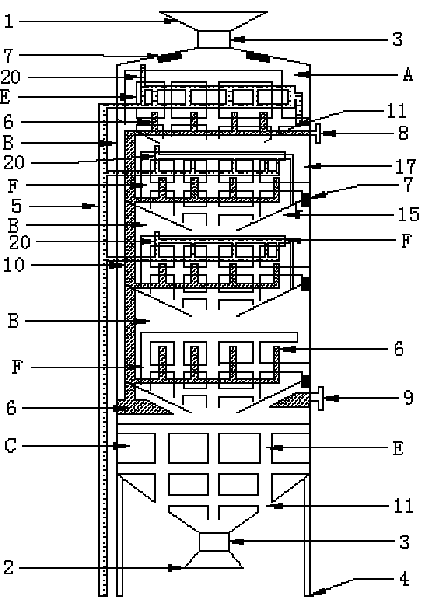

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

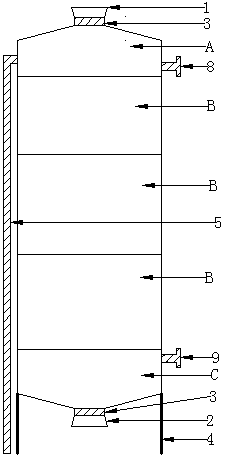

[0046] like figure 1 , figure 2 Shown: The multi-effect hot air drying tower consists of a preheating chamber (A), a drying chamber (B), a cooling chamber (C), a heat exchange and cooling device (6), a discharge valve (3), a circulation flow for ventilation and exhaust device (E), forward and reverse circulation ventilation device (F), heat pipe (10), feed inlet (1), condensation cooling device (20), exhaust pipe (17), drain pipe (5), outlet The feed port (2), the pipeline (13), and the bracket (4) are composed.

[0047] The multi-effect hot air drying tower is fixed and supported by the bracket (4) from bottom to top in order to install the cooling cabin (C), drying cabin (B) and preheating cabin (A).

[0048] The number of drying bins (B) is 3.

[0049] The upper end of the preheating chamber (A) is sequentially installed with a discharge valve (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com